Integrated upward-spiral steel dam

A steel dam and integral technology, applied in water conservancy projects, sea area projects, coastline protection, etc., to achieve good sand washing effect, simple structure, and large span of dam surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

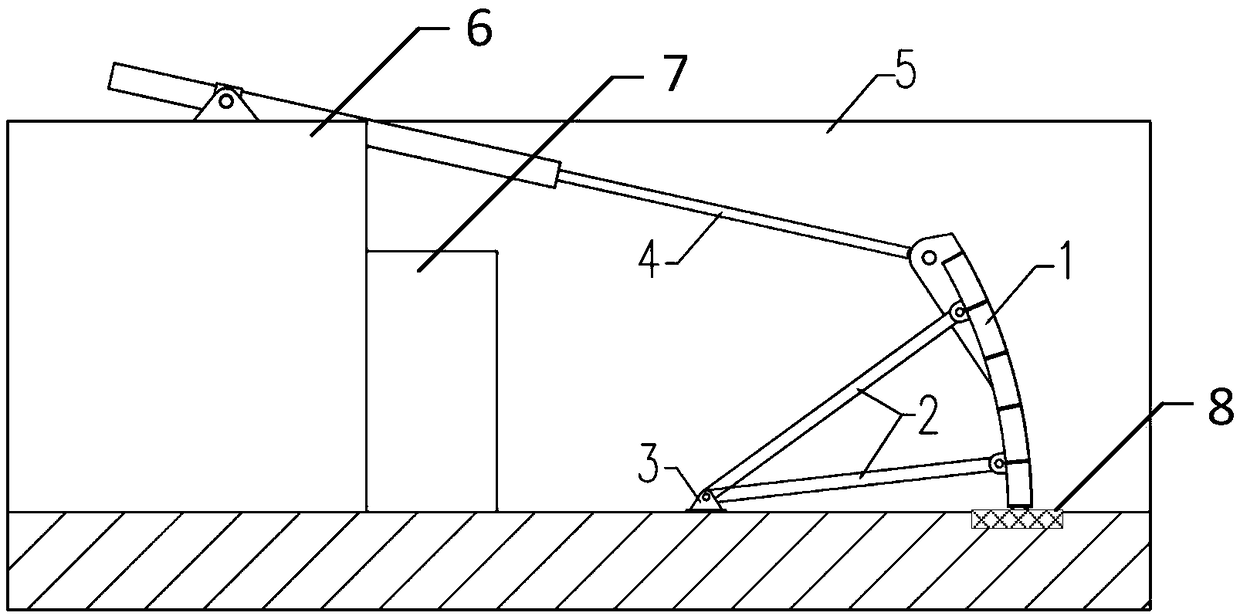

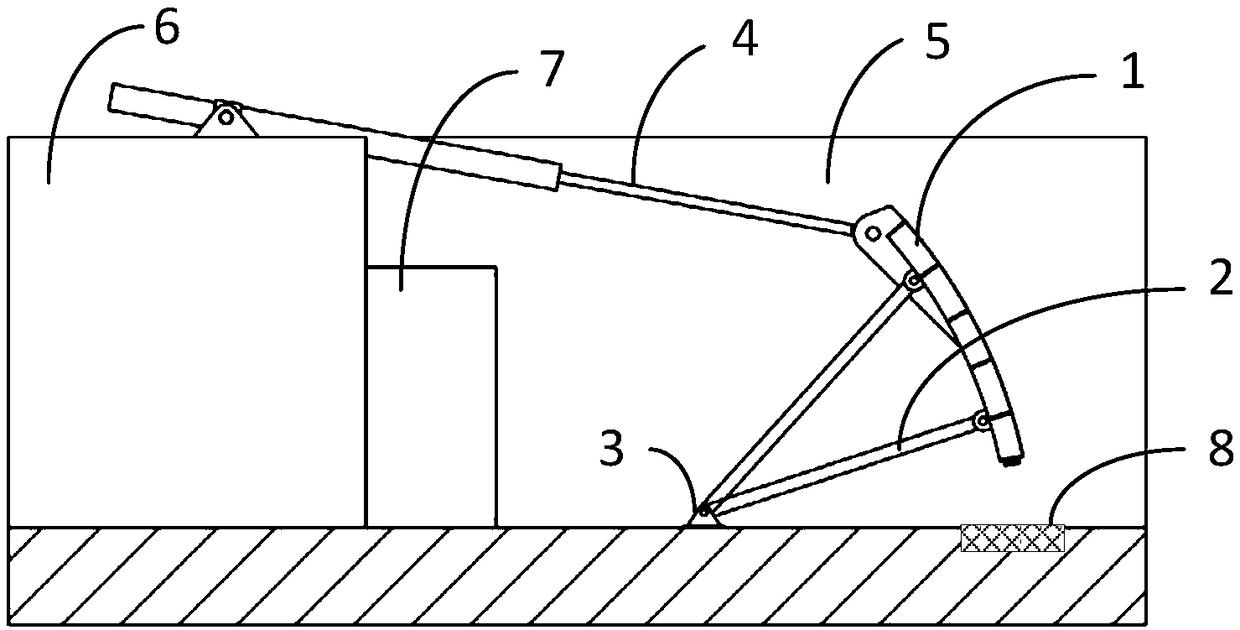

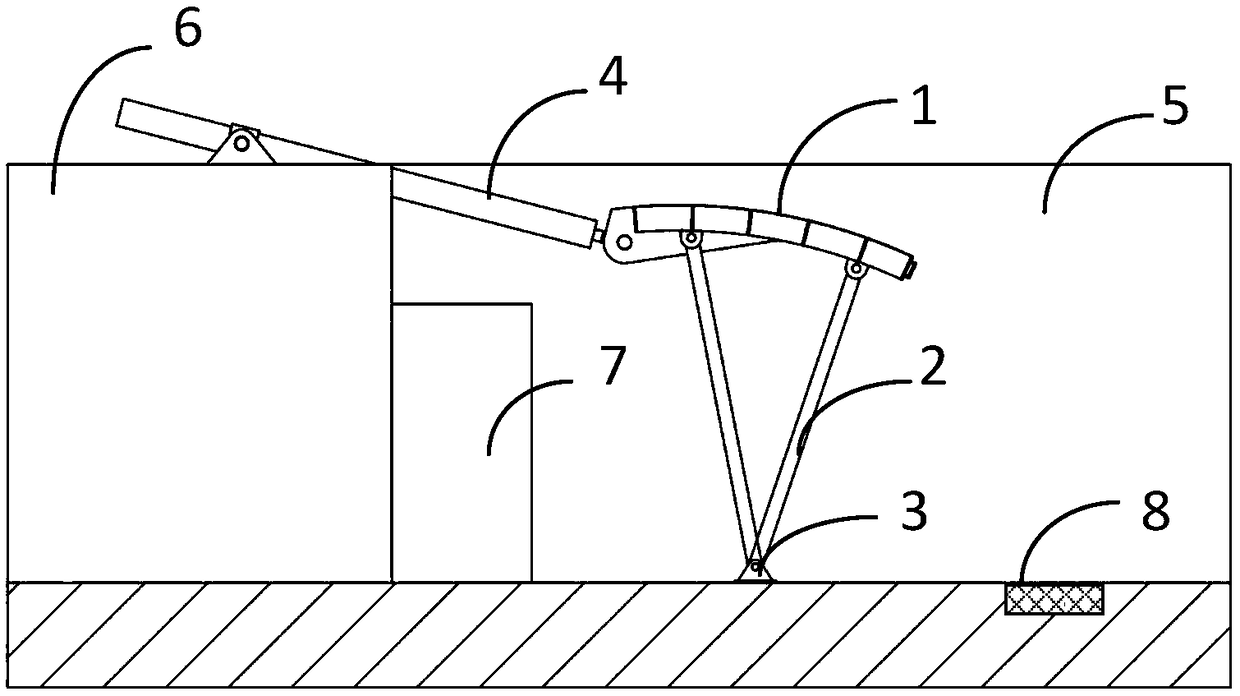

[0034] Such as Figure 1-3 As shown, the sectional view of the overall upward-swing steel dam water retention state, the sand washing and partial water release state, and the complete water release state provided by the embodiment of the present invention is shown. The overall upward-spinning steel dam includes a retaining dam surface 1, the retaining dam surface 1 is an integral structure, and the back is supported by multiple groups of supporting rotating rods 2, and each group of supporting rotating rods 2 includes multiple rotating rods that rotate around the common hinge support 3 in each group. Roots support rotating rods 2, one end of these supporting rotating rods 2 is connected to the hinge support 3, and the other end is radially connected to the back surface of the dam surface 1. The integral upturn steel dam also includes a hydraulic cylinder 4 connected to the dam surface at the end of the river. One end of the hydraulic cylinder 4 is fixed on the installation par...

Embodiment 2

[0037] Such as Figure 4-5As shown, it shows the rear view elevation view of the integral upward-swivel steel dam provided by the embodiment of the present invention when it is fully released and blocked. Comparing the two pictures, it can be seen that when the overall upper-swing steel dam is raised, the obstruction to the water flow is very small, and when the dam is erected, due to the overall dam surface structure, and the configuration of the water-stop device and the sand washing part, the water-stop effect is good.

Embodiment 3

[0039] Such as Image 6 As shown in FIG. 1 , it shows the three-dimensional display diagram of the overall upturn steel dam provided by the embodiment of the present invention. The overall upward-spinning steel dam includes a dam surface 1 spanning the entire width of the river, the dam surface 1 is an integral structure, the back is supported by multiple sets of supporting rotating rods 2, and each group of supporting rotating rods 2 is along the width direction of the river, etc. The intervals are arranged in parallel, so that the pressure exerted by the overall upward-swivel steel dam on each group of supporting rotating rods is evenly distributed, which is beneficial to improving the structural strength of the steel dam.

[0040] The hinge supports 3 are pre-buried in the dam foundation, and the connecting lines of each hinge support 3 are basically parallel to the dam surface 1 . The above setting means that each group of supporting rotating rods is arranged concentrical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com