Garbage Transfer Structure for Sweeper

A technology for transferring structures and sweeping vehicles, applied in construction, cleaning methods, road surface cleaning, etc., can solve the problems of complex structure, time-consuming, laborious, bulky, etc., and achieve the effect of simple mechanism and weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

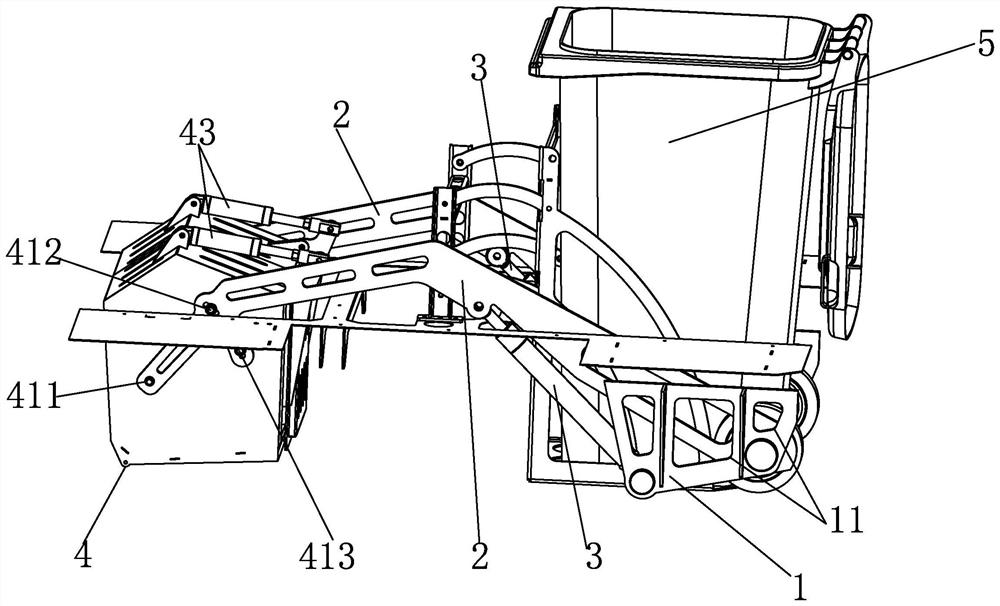

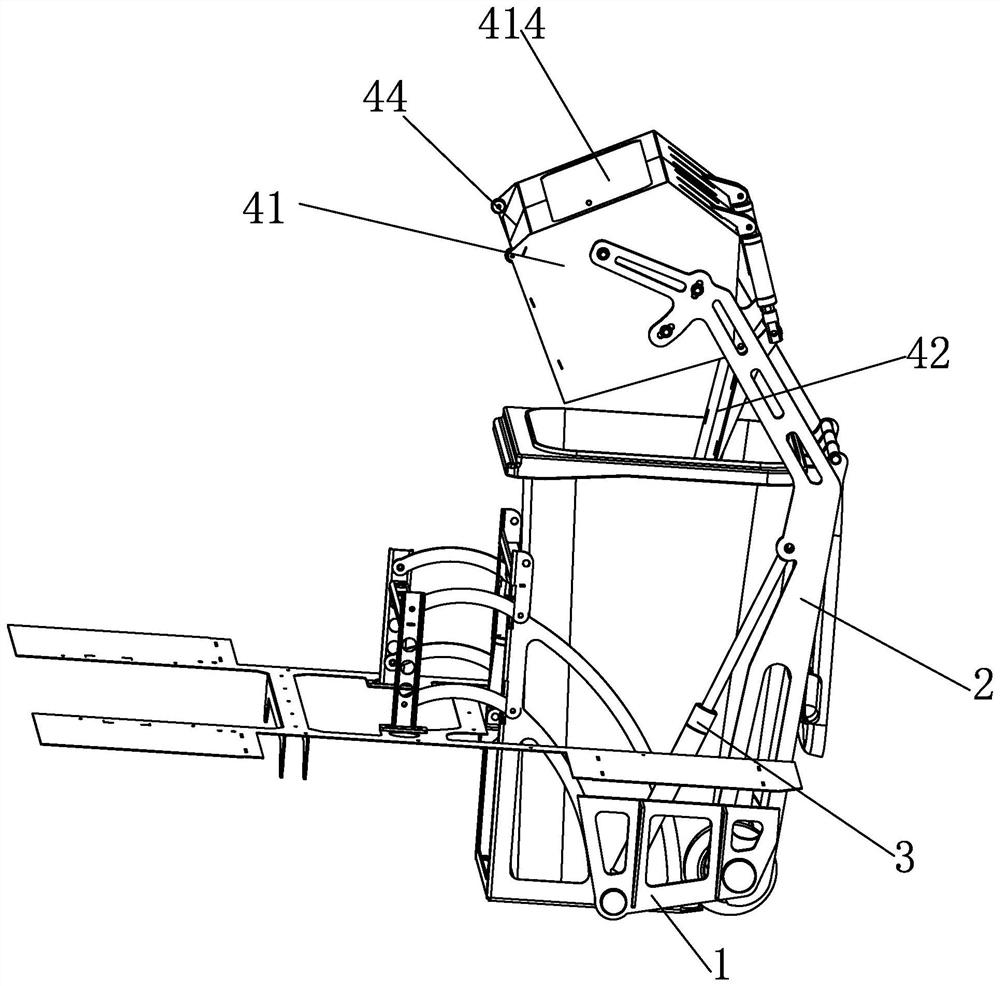

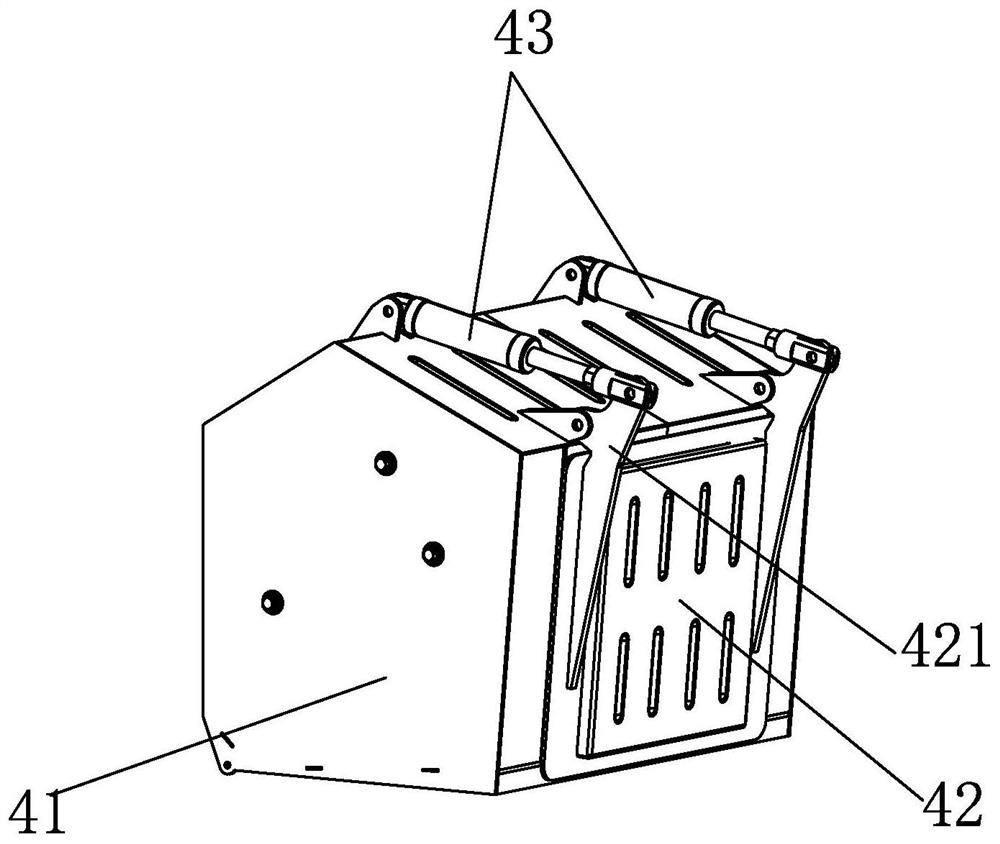

[0025] refer to Figure 1 to Figure 7 , the garbage transfer structure for sweeping vehicles, including a garbage can lifting device, the garbage can lifting device is correspondingly provided with a garbage dump structure for transferring garbage, and the garbage can lifting device includes a lifting frame 6, a fixed frame 7, and a hydraulic mechanism 8, 4 movable connecting rods 9, 2 vertical columns 10, garbage can 5.

[0026] The hydraulic mechanism 8 includes a cylinder body 81 and a piston 82 .

[0027] The movable connecting rod 9 is configured as an arc.

[0028] The fixed frame 7 includes a main body 71, a connecting small plate 72, two vertical bars 73, a cross bar 74, and a large connecting plate 75. The main body 71 is fixed on the sweeper, and one end of the vertical bar 73 is connected to the small The plate 72 is fixed on the main body 71 and symmetrically distributed on both sides of the center line of the main body 71. The two ends of the horizontal bar 74 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com