A handbag automatic thread cutting device

An automatic, handbag technology, applied in the cutting of textile materials, the mechanism of cutting threads in sewing machines, textiles and papermaking, etc., can solve the problems of scratches on PU leather, fission of the stitching mouth, and affect the appearance, so as to achieve full thread cutting, The effect of increasing the tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

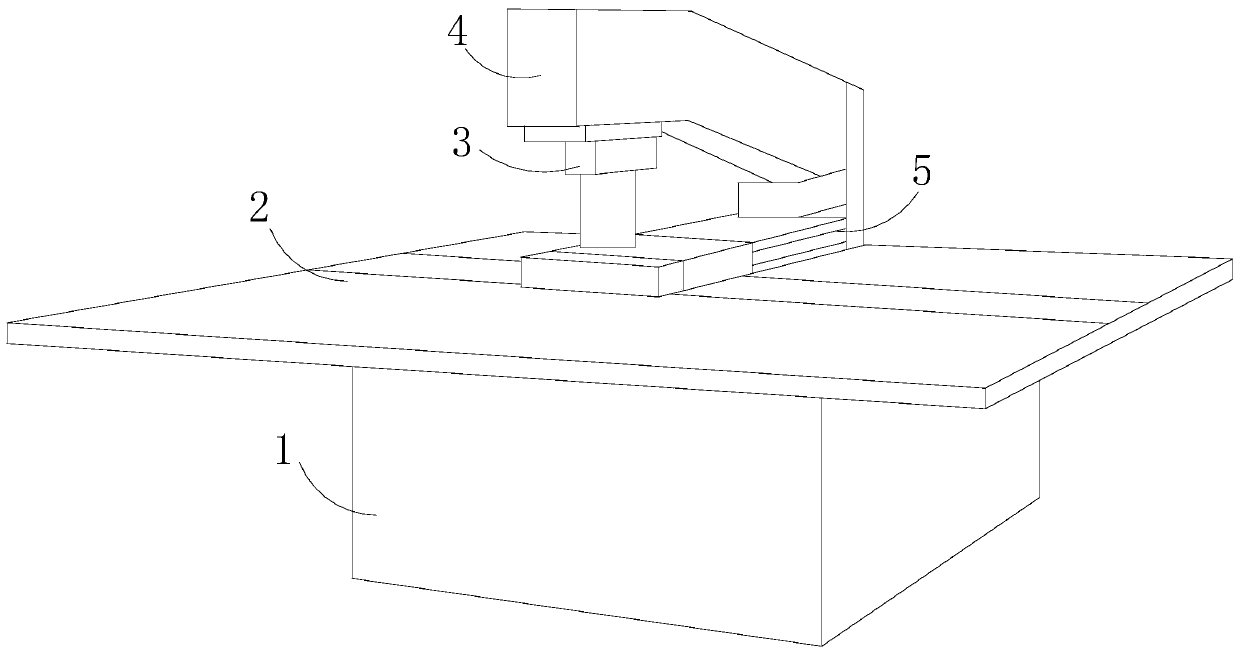

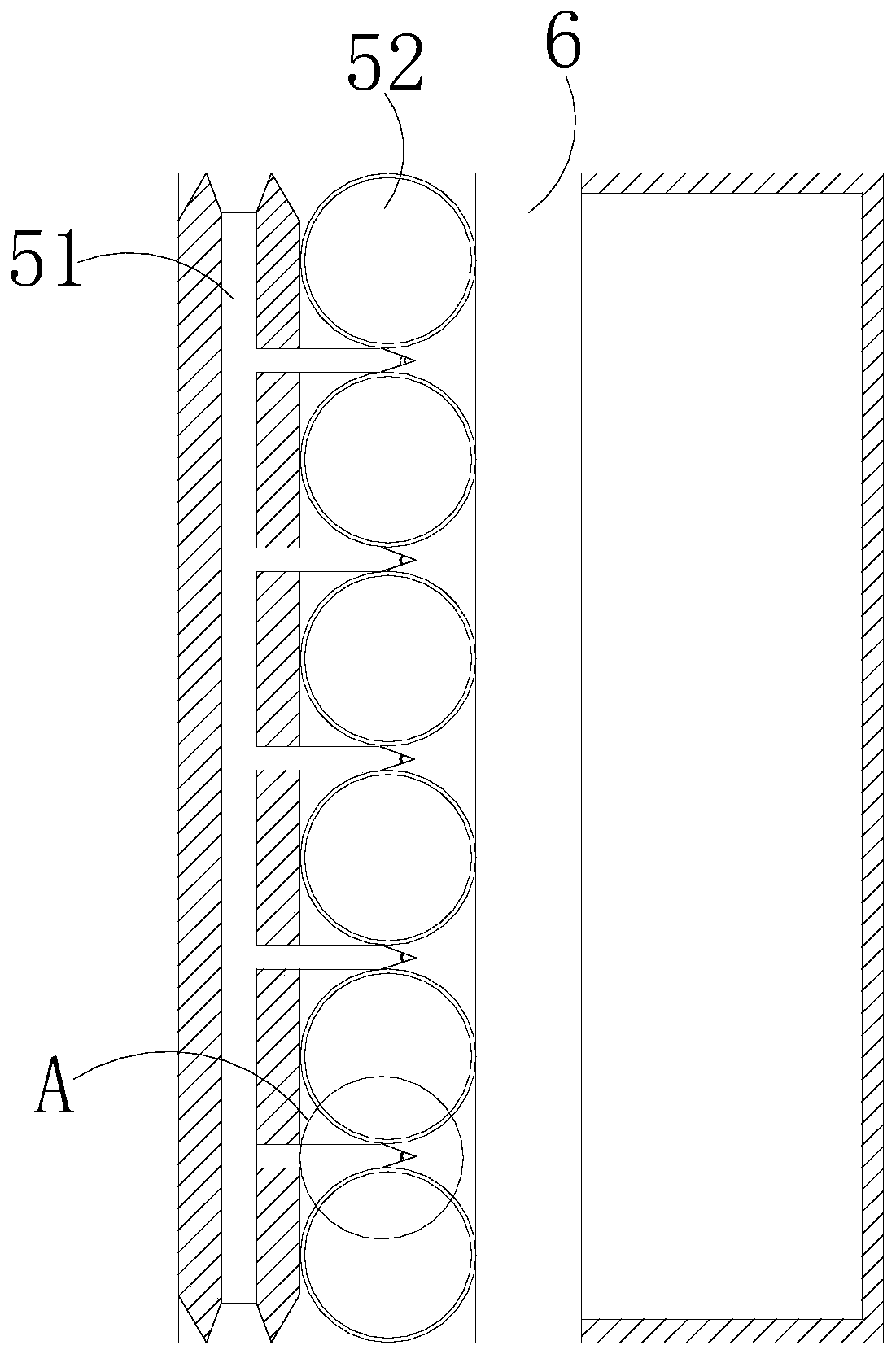

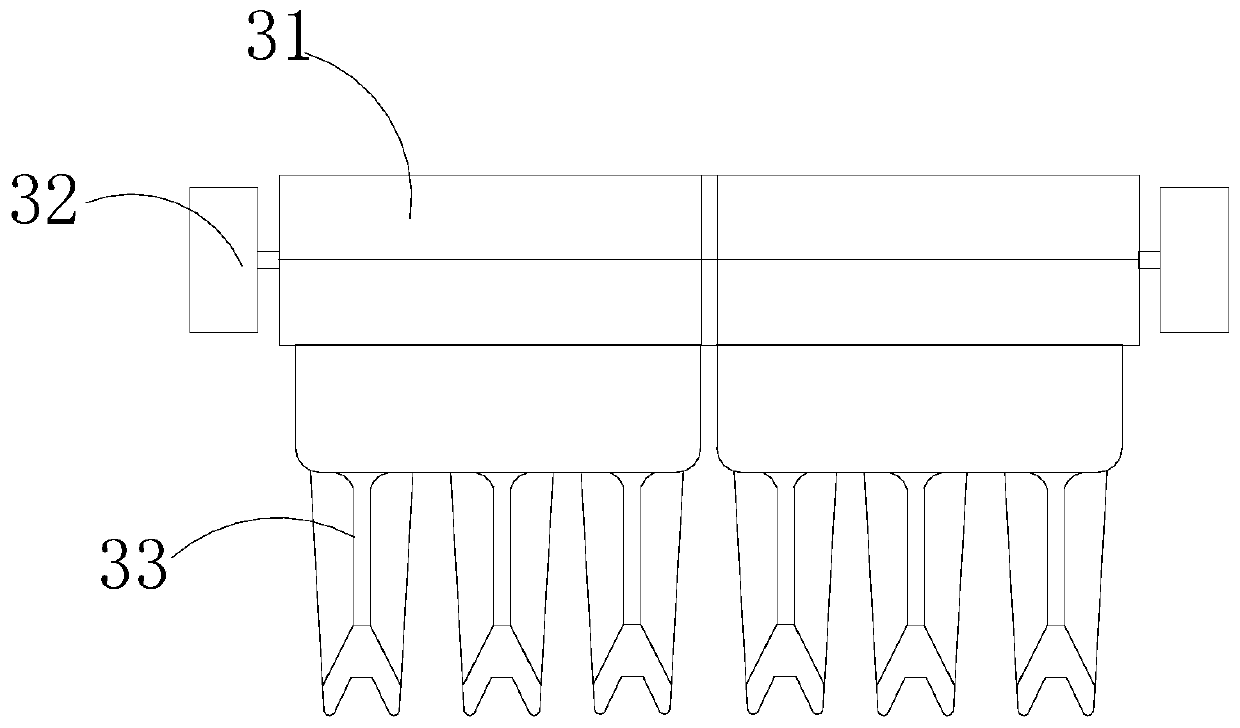

[0033] like Figure 1-Figure 9 As shown in the figure, the present invention provides an automatic thread trimming device for handbags. The platform 2 is an integrated structure, and a placement mechanism 5 is installed on the side of the support platform 2, wherein the placement mechanism 5 is mechanically connected with the machine head 4, and the other bottom end of the machine head 4 away from the placement mechanism 5 is provided. There is a cutter mechanism 3 and is matched with the horizontal extension end of the placement mechanism 5. The placement mechanism 5 is divided into a left cavity and a right cavity, and a trimming line matched with the cutter mechanism 3 is formed between the left cavity and the right cavity. Channel 6, and the left chamber contains a gas generating tube 51 and an electrostatic ball 52, while the right chamber is provided with a counterweight pressure plate 53 and a pressing assembly 54, the cutter mechanism 3 includes a control end 31, beari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com