End suturing device for suture manipulator for composite material and stitch forming method thereof

A composite material and sewing device technology, applied in the direction of sewing machine control devices, sewing equipment, sewing machine components, etc., to achieve the effect of reducing the puncture space, overcoming the limited position, and small puncture space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

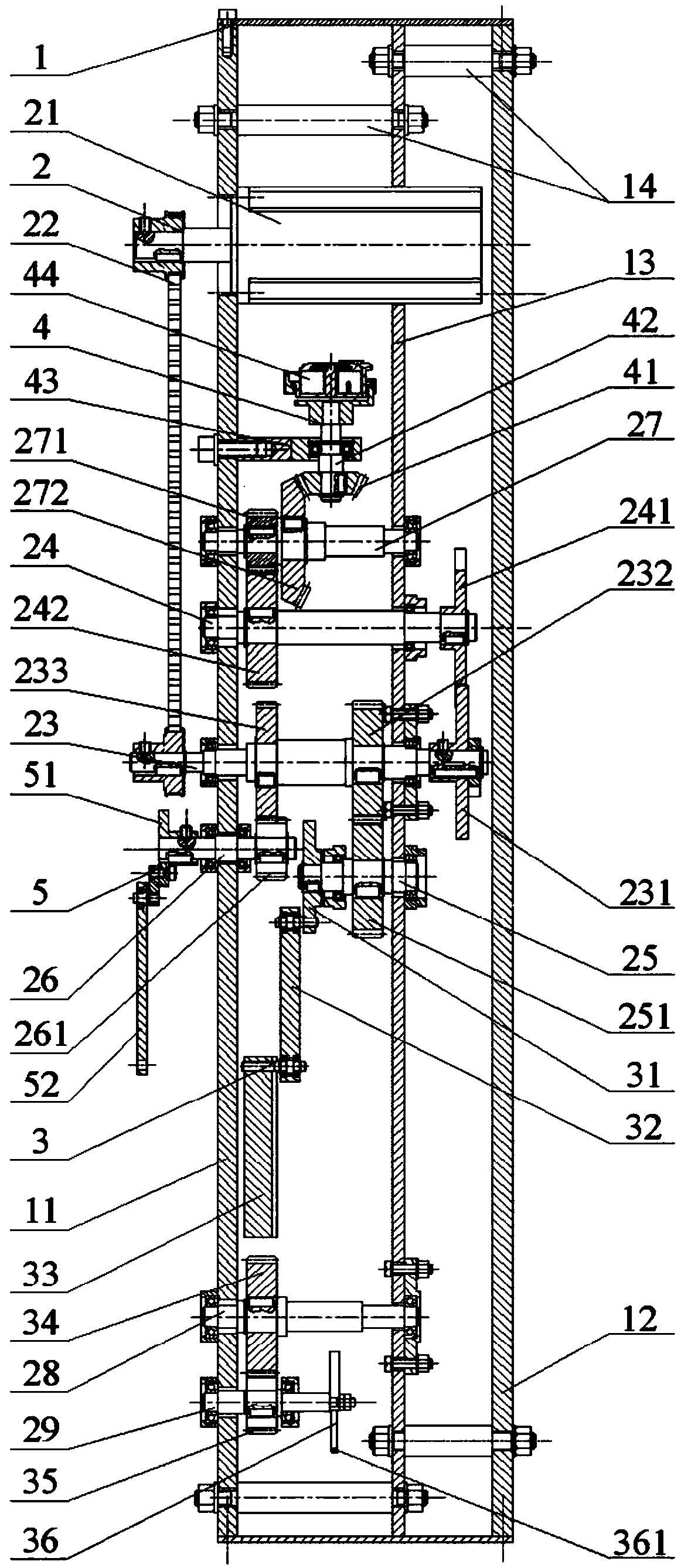

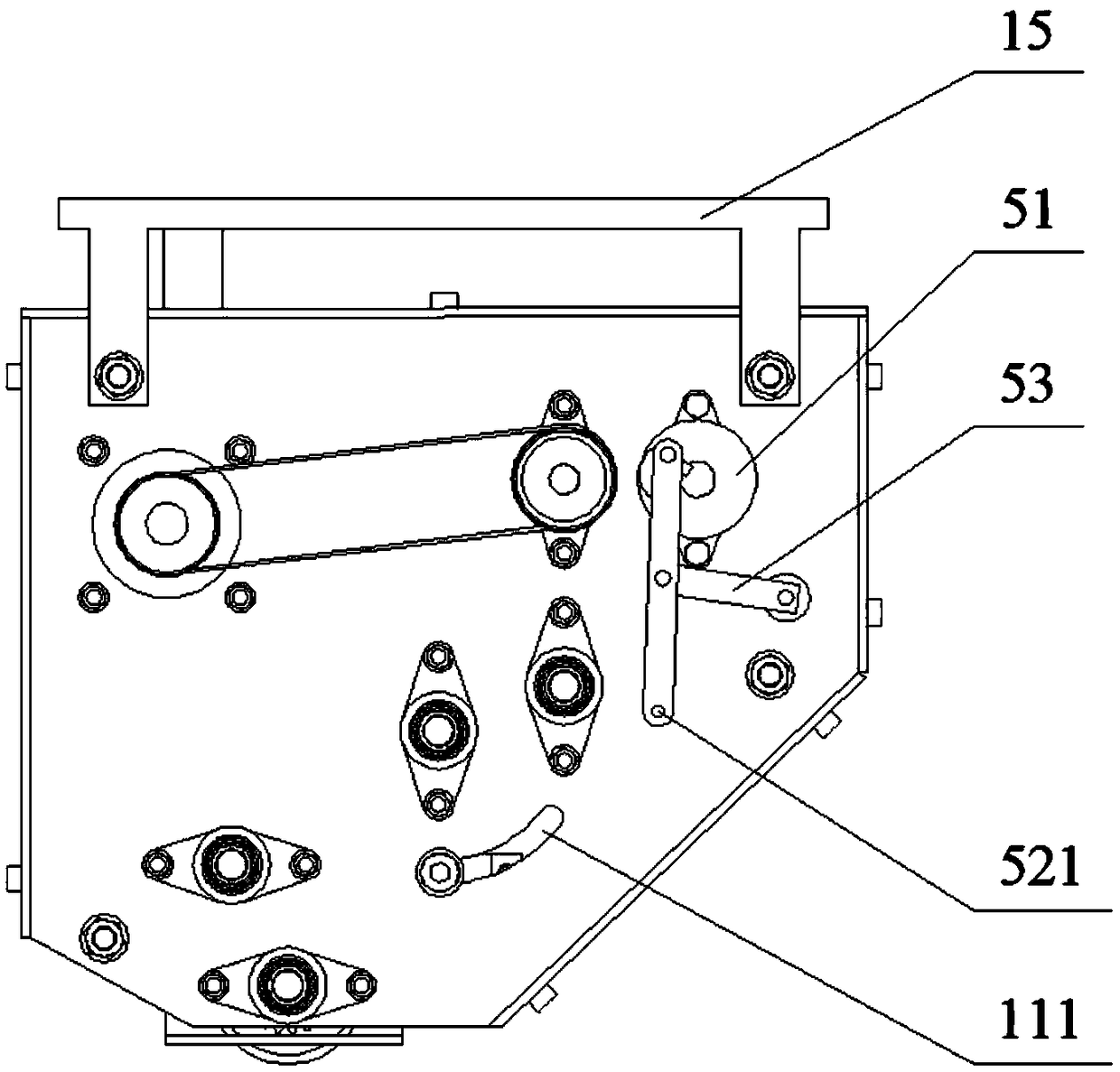

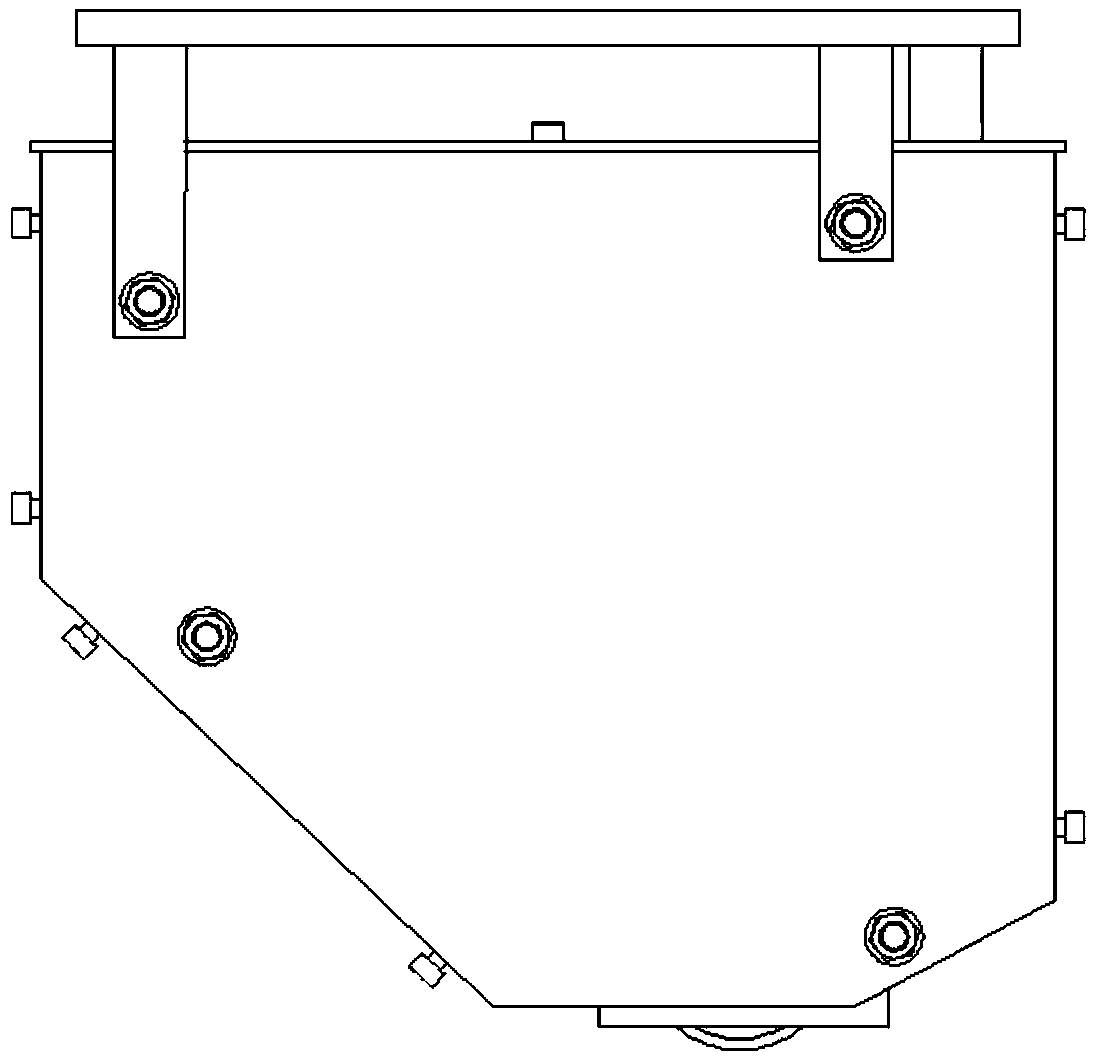

[0058] Such as Figure 1 to Figure 7 As shown, a terminal sewing device of a three-dimensional textile composite sewing manipulator of the present invention includes a frame 1, a driving mechanism 2, a stabbing mechanism 3, a thread locking mechanism 4, and a thread feeding mechanism 5; The front baffle 11, the back baffle 12 and the liner 13; between the front baffle 11 and the liner 13, between the liner 13 and the back baffle 12 are fixed with several support shafts 14 by bolts, so The top of the frame 1 is provided with a flange 15 for matching with the end of the industrial robot, and the flange 15 is fixedly connected to the top of the front baffle 11 and the rear baffle 12 through bolts; the drive mechanism 2 includes a through The motor 21 arranged between the front baffle 11 and the liner 13 is fixedly connected to the front baffle 11 by screws, and the end of the output shaft of the motor 21 is connected to one end of the first transmission shaft 23 through a belt dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com