Microwave radiation water-film-type drinking water sterilizing system

A microwave radiation and drinking water technology, applied in water/sewage treatment, light water/sewage treatment, water/sewage treatment equipment, etc. Harm and other problems, to achieve the effects of high microwave energy utilization, improved microwave sterilization effect, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

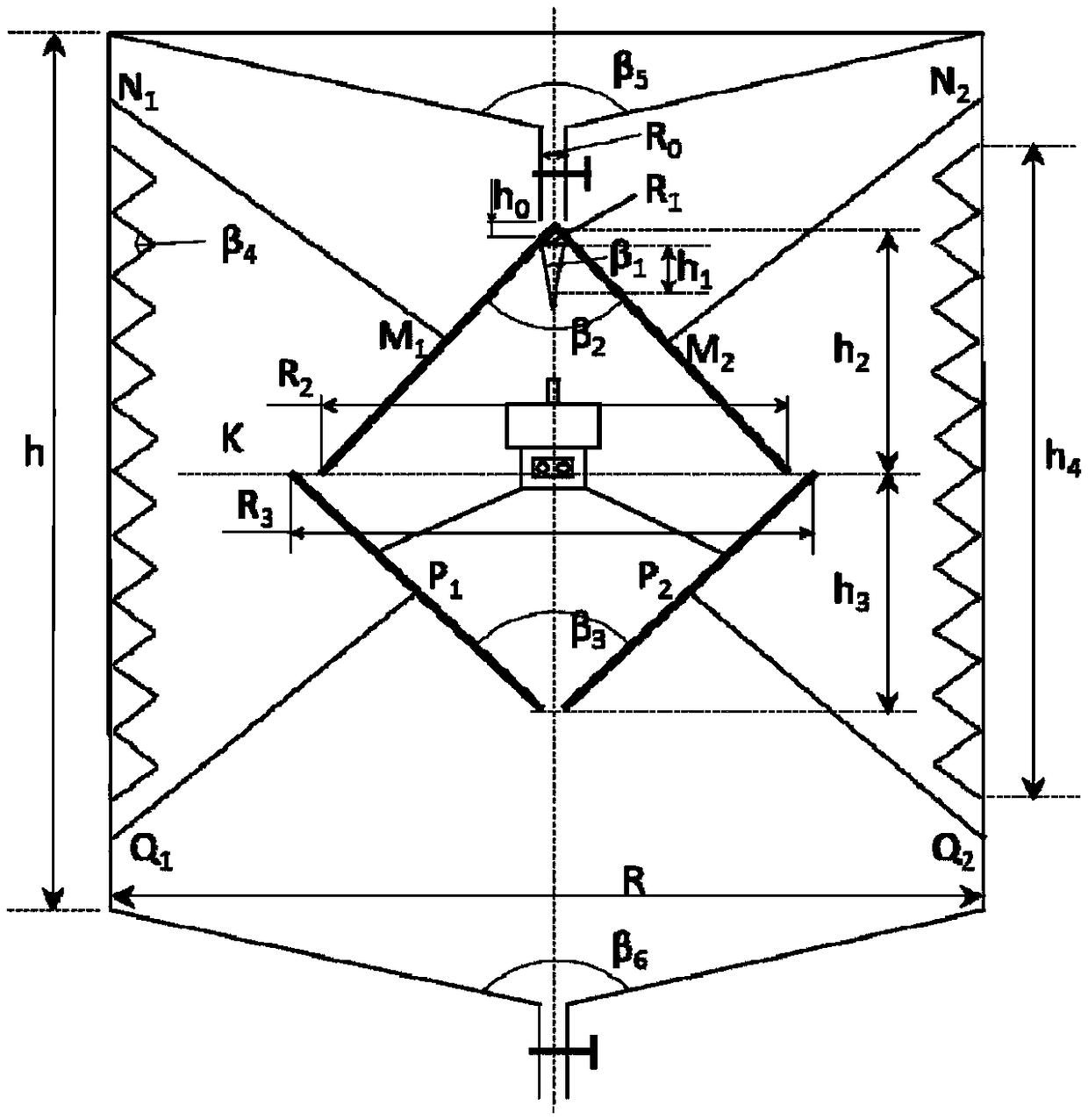

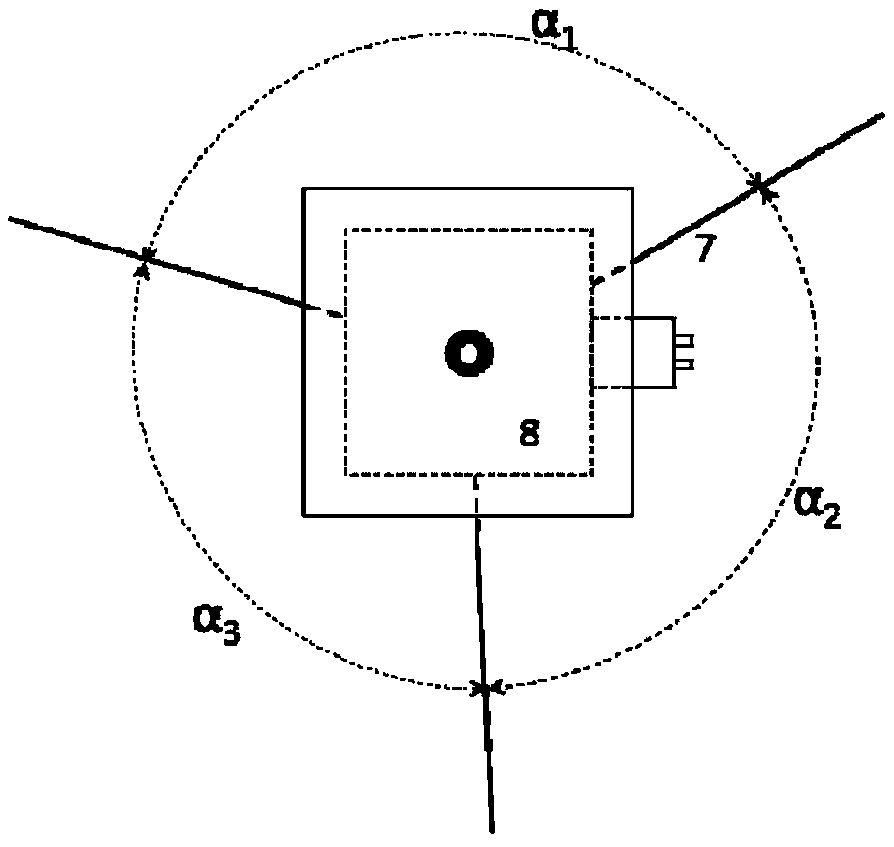

[0033] Such as Figure 1 ~ Figure 4 As shown, it includes water storage room 1 to be disinfected, zigzag microwave scattering plate 2, microwave cavity 3, built-in flow regulating valve 4, microwave scattering cone 5, upper water film forming plate 6, magnetron pillar 7, magnetron Pipe 8, lower water film forming plate 9, sterilized water storage area 10, external valve 11, wall 12, the microwave cavity 3 is surrounded by the upper water film forming plate 6 and the lower water film forming plate 9 Divided into microwave work area I and microwave work area II, the lower part of the sterilized water storage room 1 is a circular vertical water inlet A, and the lower part of the sterilized water storage area 10 is a circular vertical water outlet B. The upper water film forming plate 6 is suspended by three suspension chains 13 , and the lower water film forming plate 9 is supported by three inclined columns 14 . The system directly places the magnetron inside the microwave cavi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com