Automobile cylinder cover feeding and discharging device

A technology of reclaiming device and cylinder head, which is applied to conveyor objects, transportation and packaging, etc., can solve the problems of slowing down work efficiency, affecting the accuracy of detection, skew penetration, etc., achieving high safety, high grasping rate, smooth forward effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

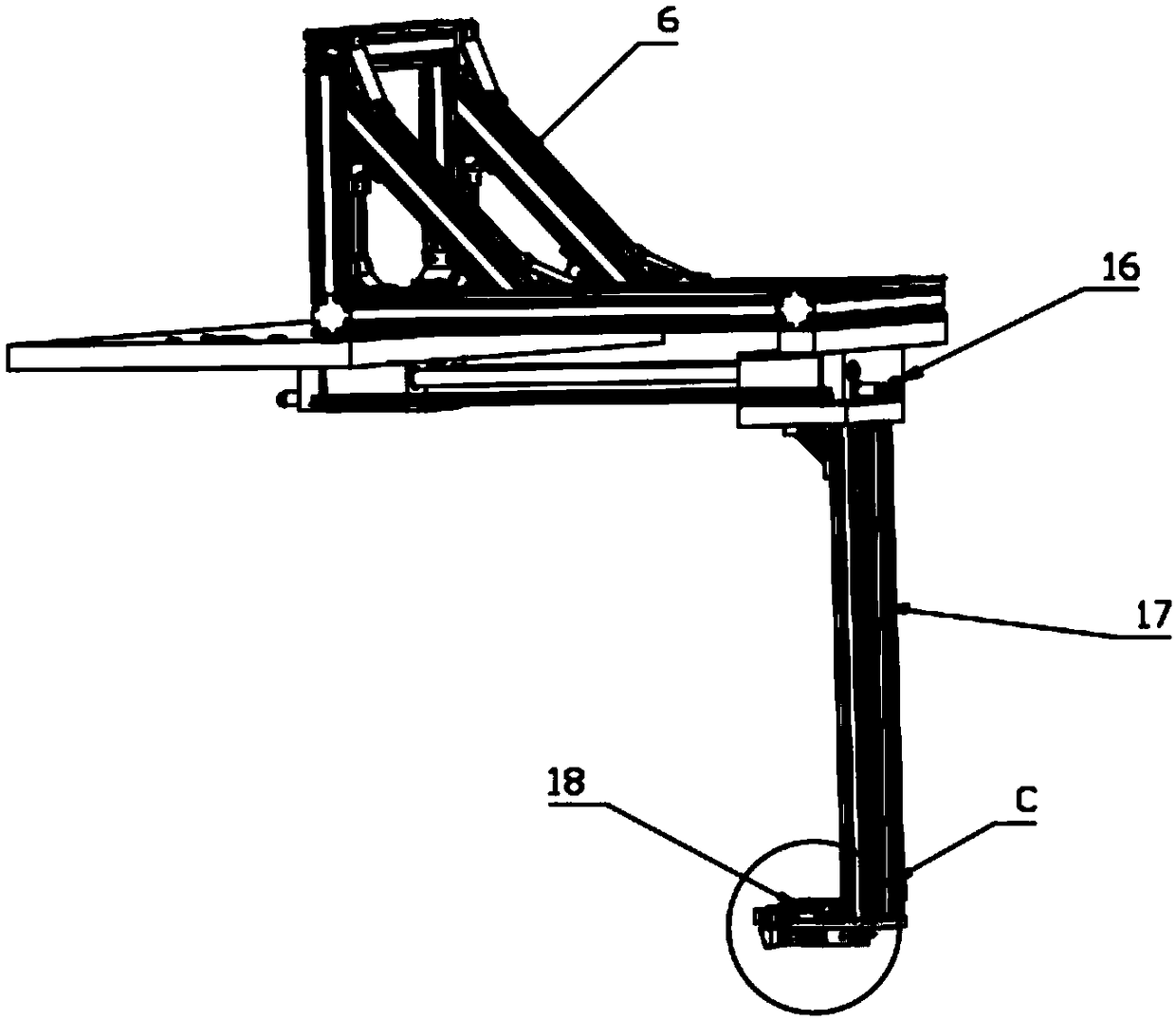

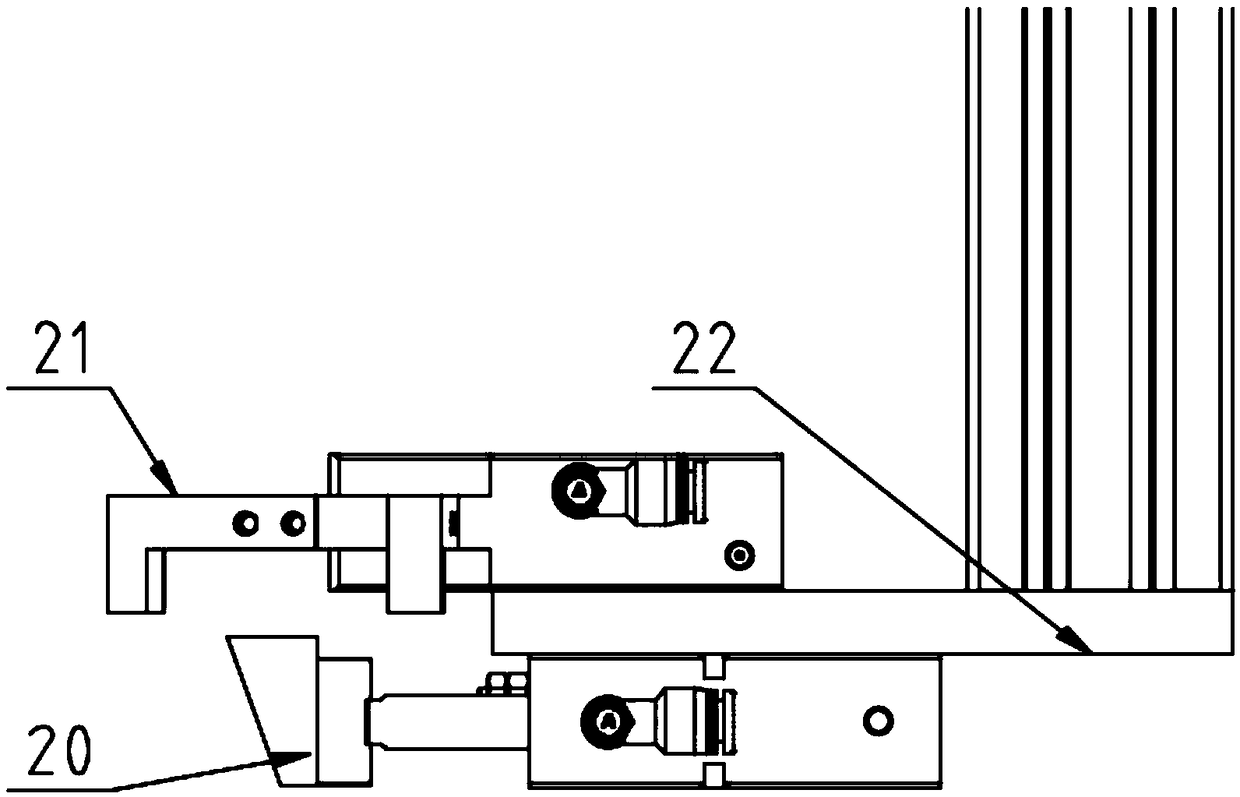

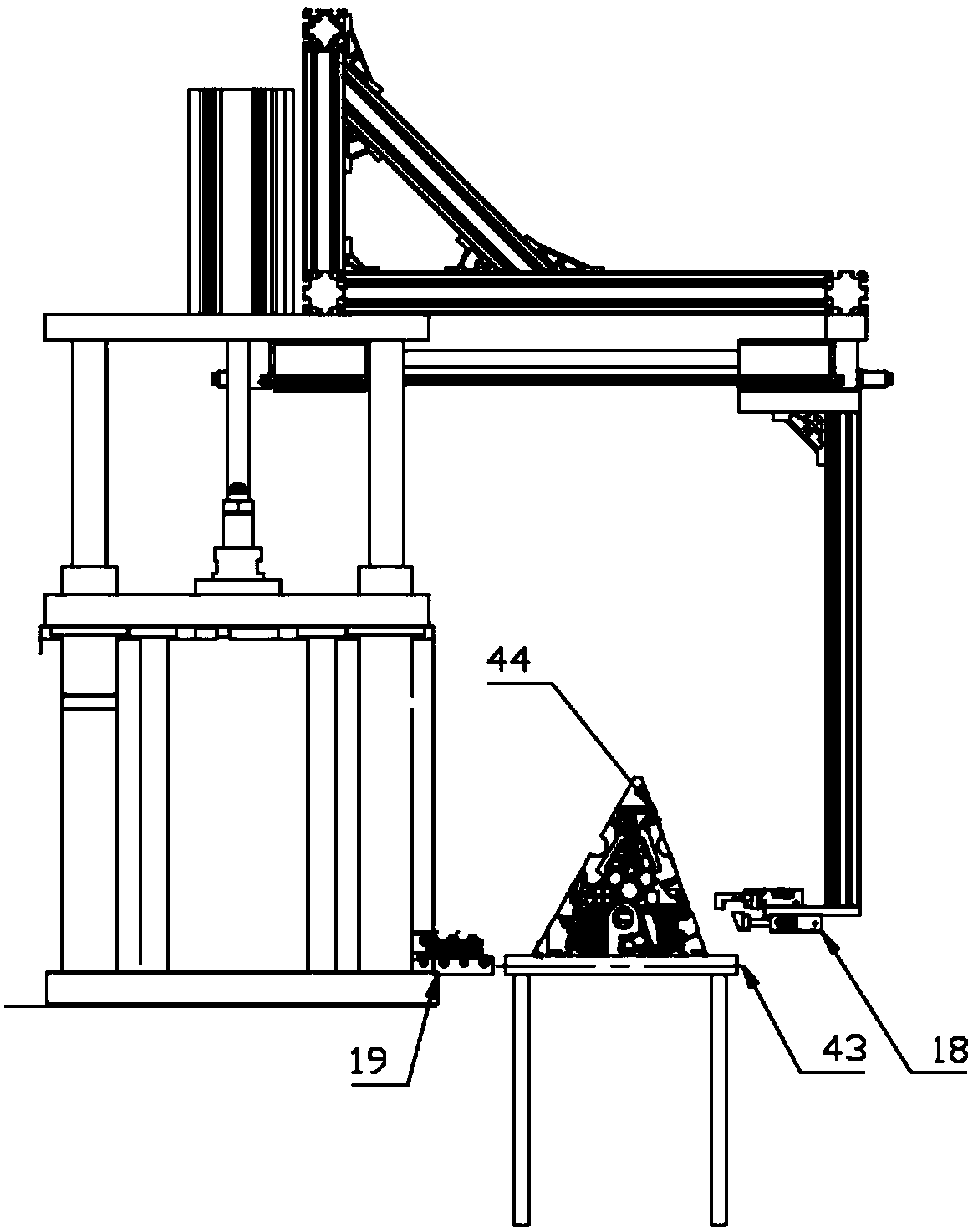

[0022] Such as figure 1 As shown, the automobile cylinder head feeding and retrieving device includes a mounting frame 6, a rodless cylinder 16, a connecting rod 17, and a feeding handle 18. The mounting frame 6 is an aluminum alloy profile, and the rodless cylinder 16 is located on the mounting frame 6. On the top, the connecting rod 17 is installed on the slider of the rodless cylinder 16, and the lower end of the connecting rod 17 is equipped with a mounting plate 22; The upper side of the pusher rod 20 is installed on the lower side of the mounting plate 22; when the feeding gripper 18 is feeding, the ejector rod 21 is in the state of opening to both sides, and the cylinder that controls the pusher rod stretches out to feed, and the ejector When push rod cylinder is retracted and material return rod 21 merges to the center and hooks the casting rib on the cylinder head to be tested under the drive of the cylinder controlling the material return rod, the cylinder head to be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com