High-accuracy full-automatic film adhering equipment

A film lamination equipment and fully automatic technology, applied in the field of high-precision automatic lamination equipment, can solve the problems of inability to protect the film and lamination, insufficient automation, poor lamination accuracy, etc., to improve lamination precision and lamination efficiency, and overall reliability. The effect of saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings.

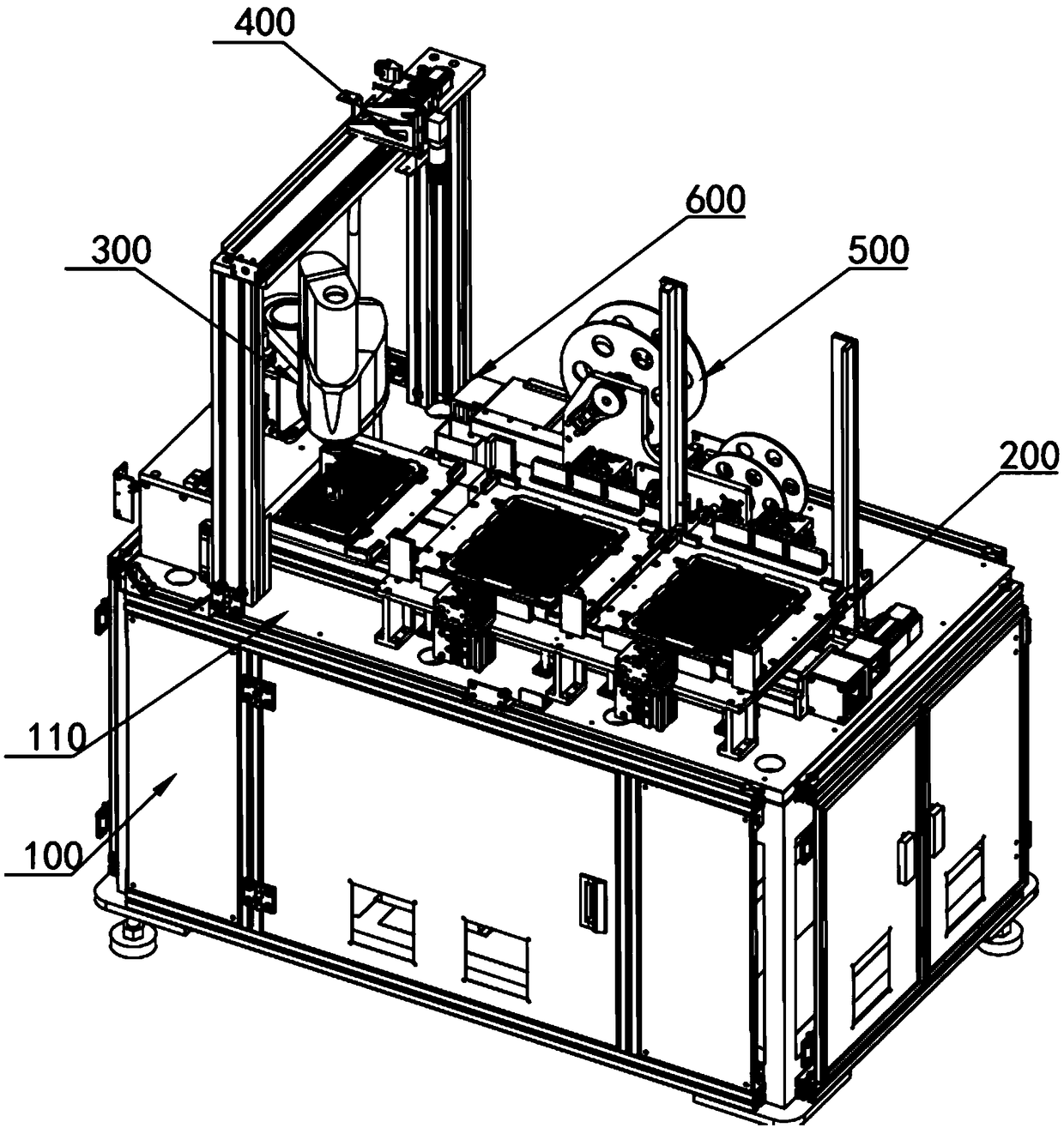

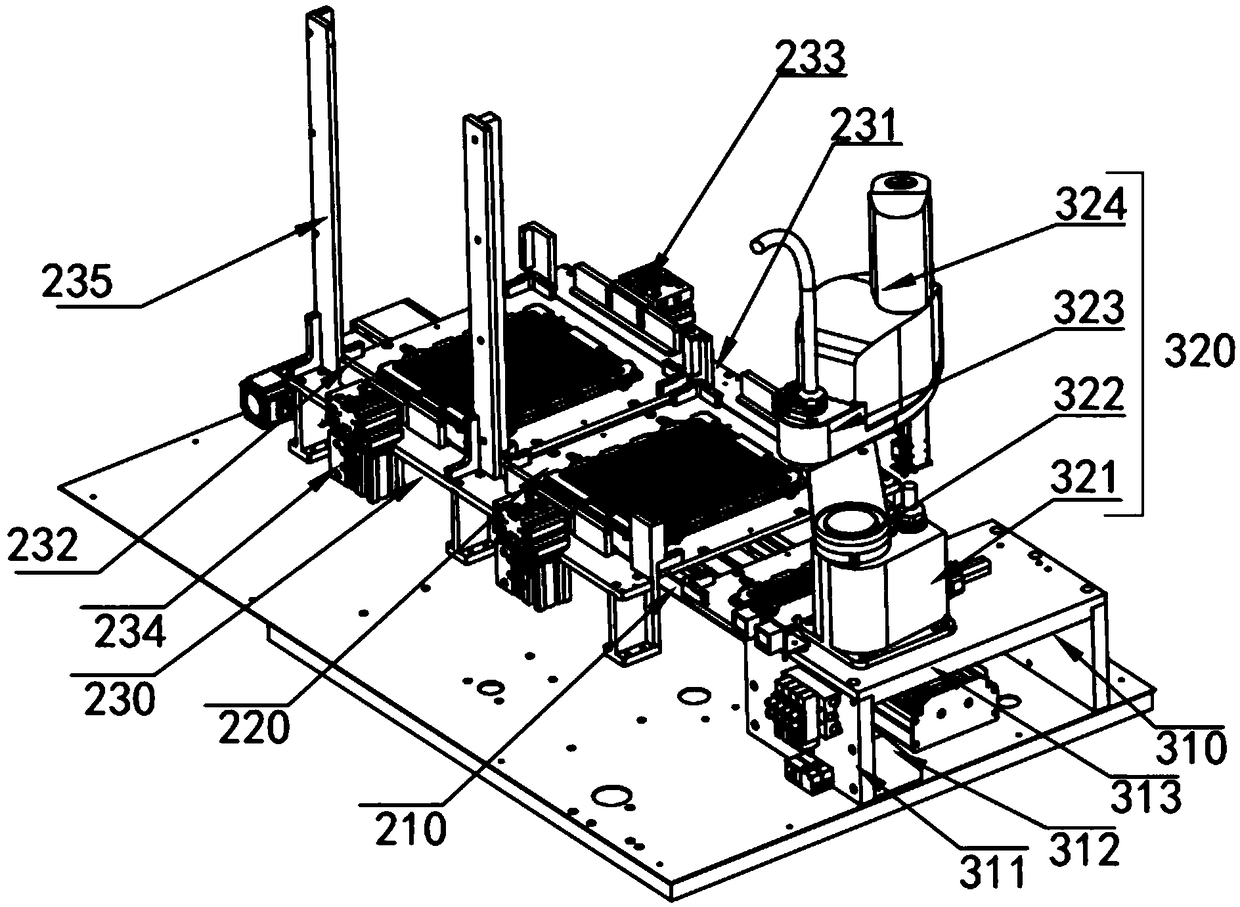

[0033] Such as Figure 1 ~ Figure 2 As shown, a high-precision automatic film sticking equipment 10 includes a frame 100, a workbench 110 arranged on the upper part of the frame 100, and a feed-in and out-feed mechanism 200 arranged on the workbench 110 for loading and unloading products, and arranged on the workbench 110 is located at one end of the feeding and discharging mechanism 200, and the automatic film sticking manipulator 300 that automatically takes the material and sticks the film is set on the workbench 110 and is located above the manipulator. The unwinding mechanism 500 for unwinding and rewinding the film material is located on the side of the unwinding mechanism 500 and the stripping mechanism 600 for peeling off the film material is arranged on the frame 100 for controlling the control mechanism 700 for controlling the work of the film sticking equipm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com