Novel laser cutting machine

A technology of laser cutting machine and laser cutting head, applied in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve the problems of difficult cutting of similar products, limited moving range of cutting head, narrow product category, etc., to achieve the processing range Large, versatile and flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings.

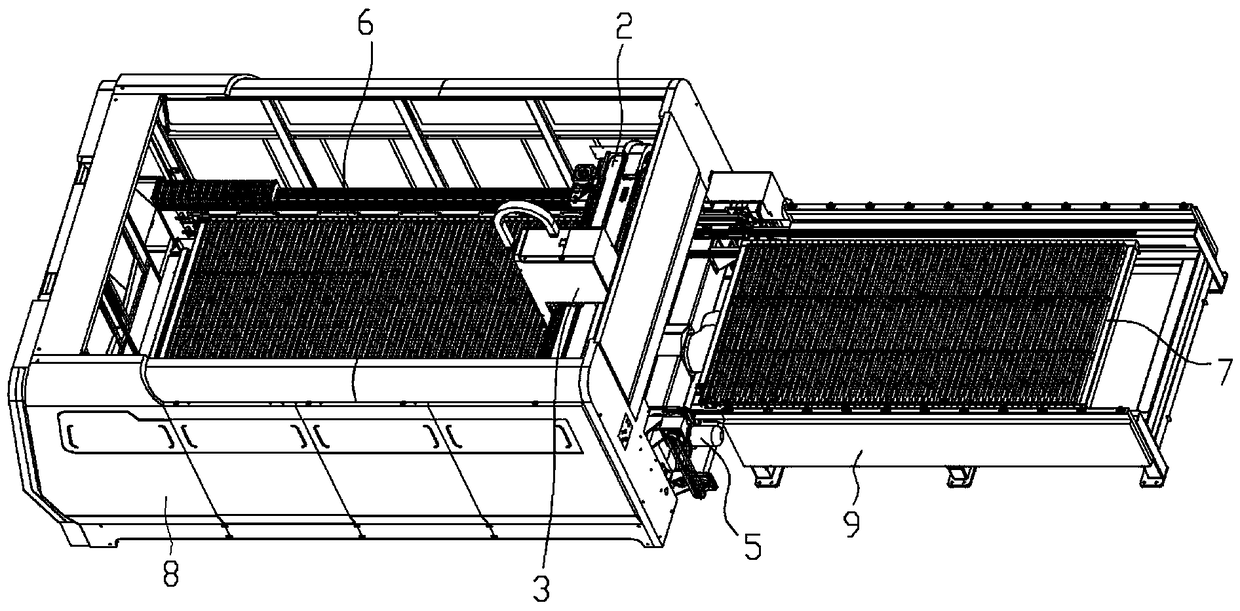

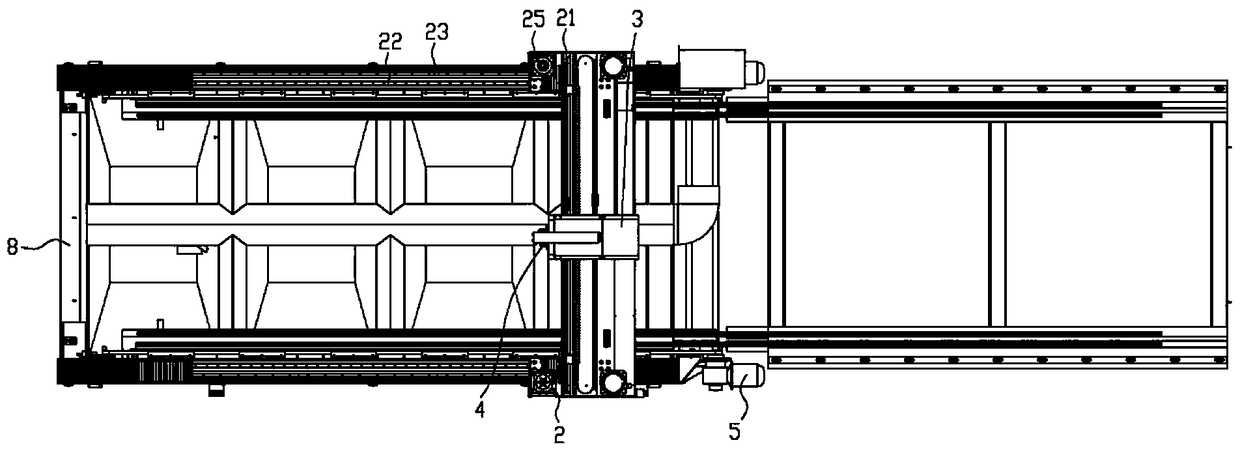

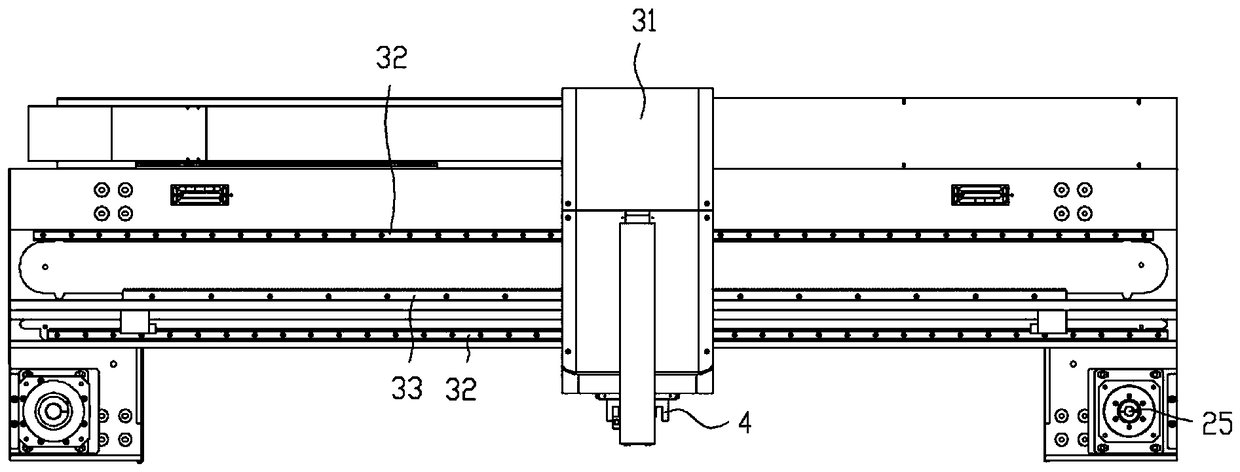

[0028] refer to figure 1 — Figure 11 , a new type of laser cutting machine of the present invention, including a laser cutting head 1, a left and right moving mechanism 2, a front and rear moving mechanism 3, an up and down moving mechanism 4, a dual-power double-drag mechanism 5, an upper workbench 6, a lower workbench 7, Working fuselage 8 and feeding fuselage 9.

[0029]The working body 8 comprises a bed 81, a front support 82, a rear support 83, an outer cover 84, and an air extraction interface 85. One side of the bed 81 is fixedly connected with the front support 82 by bolts, and the other side is fixedly connected with the rear support 83 by bolts. , the inner wall of one end of the front bracket 82 and the outer cover 84 is fixedly connected by bolts, and the inner side wall of the other end of the rear bracket 83 and the outer cover 84 is fixedly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com