Multi-station riveting and pressing device

A multi-station, riveting technology, applied in the field of riveting, can solve the problems of complex process, damage, difficult to fit parts, etc., to achieve the effect of strong pertinence, easy fixation, and increased work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below in conjunction with illustrations and specific embodiments.

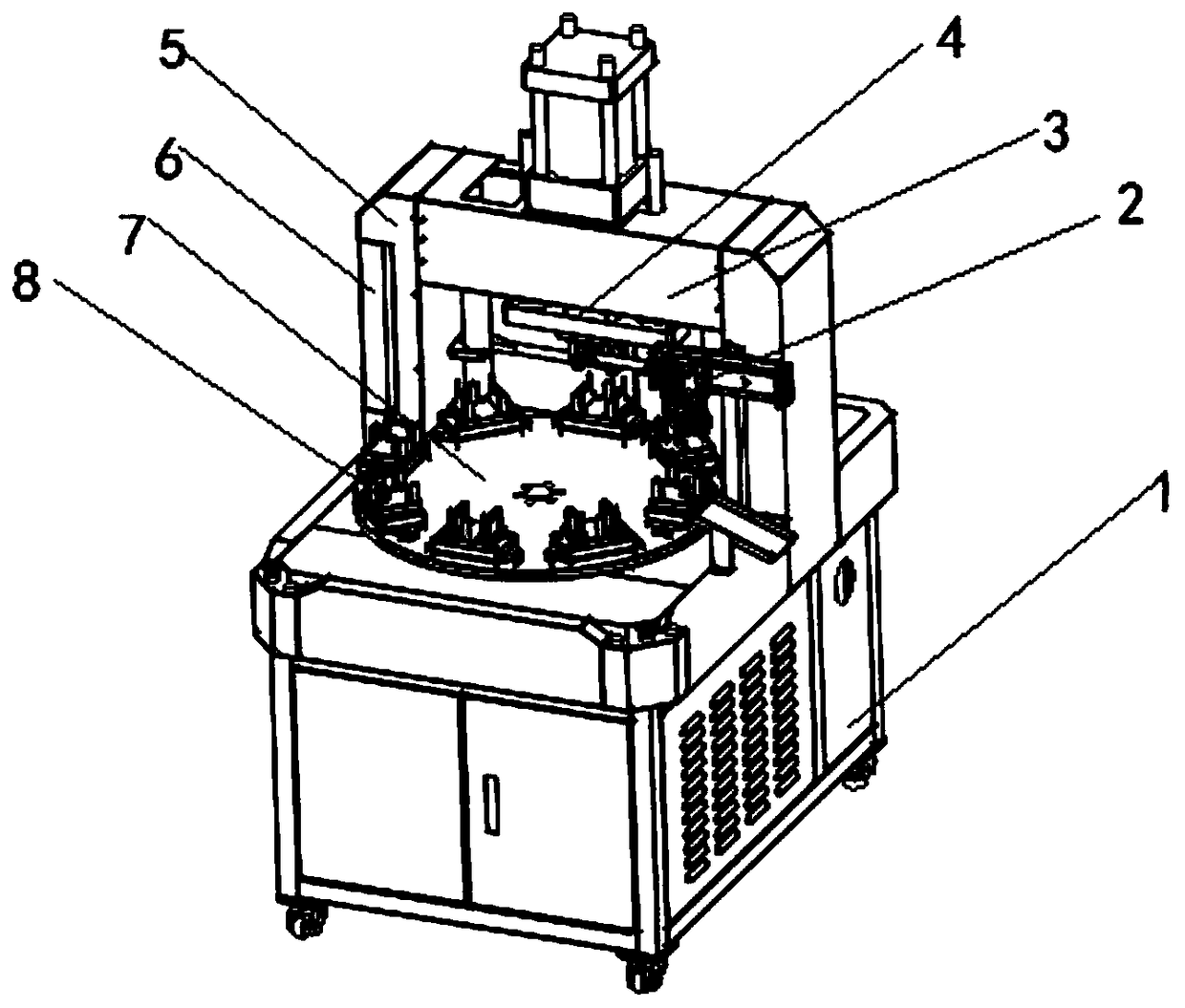

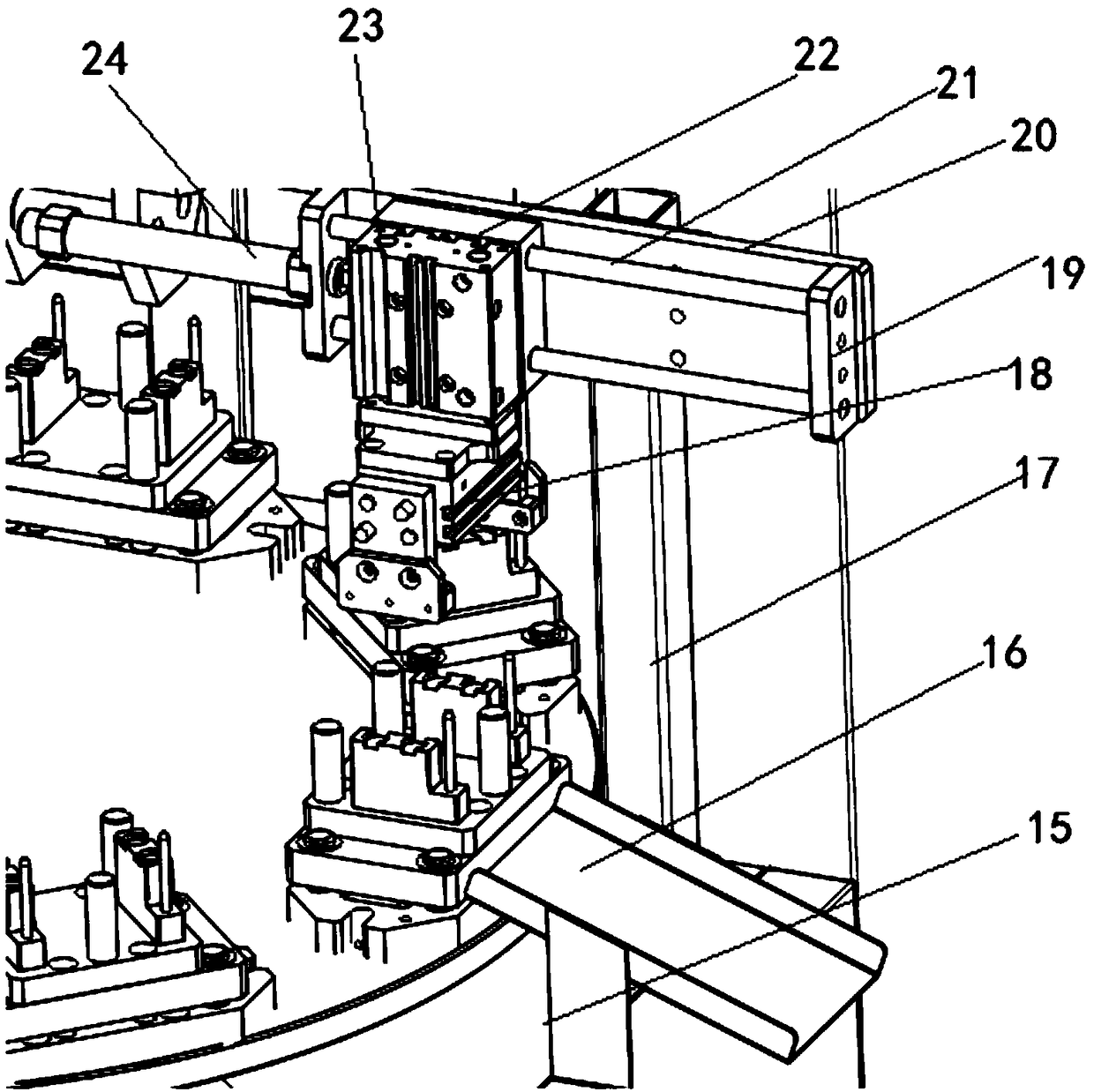

[0020] Such as Figure 1-4 A multi-station riveting device is shown, comprising a workbench 1, a turntable 7 is installed on the workbench 1, eight clamps 8 are evenly installed on the circumference of the turntable 7, and the turntable 7 A support frame is installed on the rear end workbench, a riveting mechanism 4 is installed on the support frame, and a material transfer mechanism 2 is also installed on one side of the turntable 7;

[0021] The rotating shaft at the lower end of the turntable 7 is connected with a geared motor, and the geared motor drives the turntable to rotate;

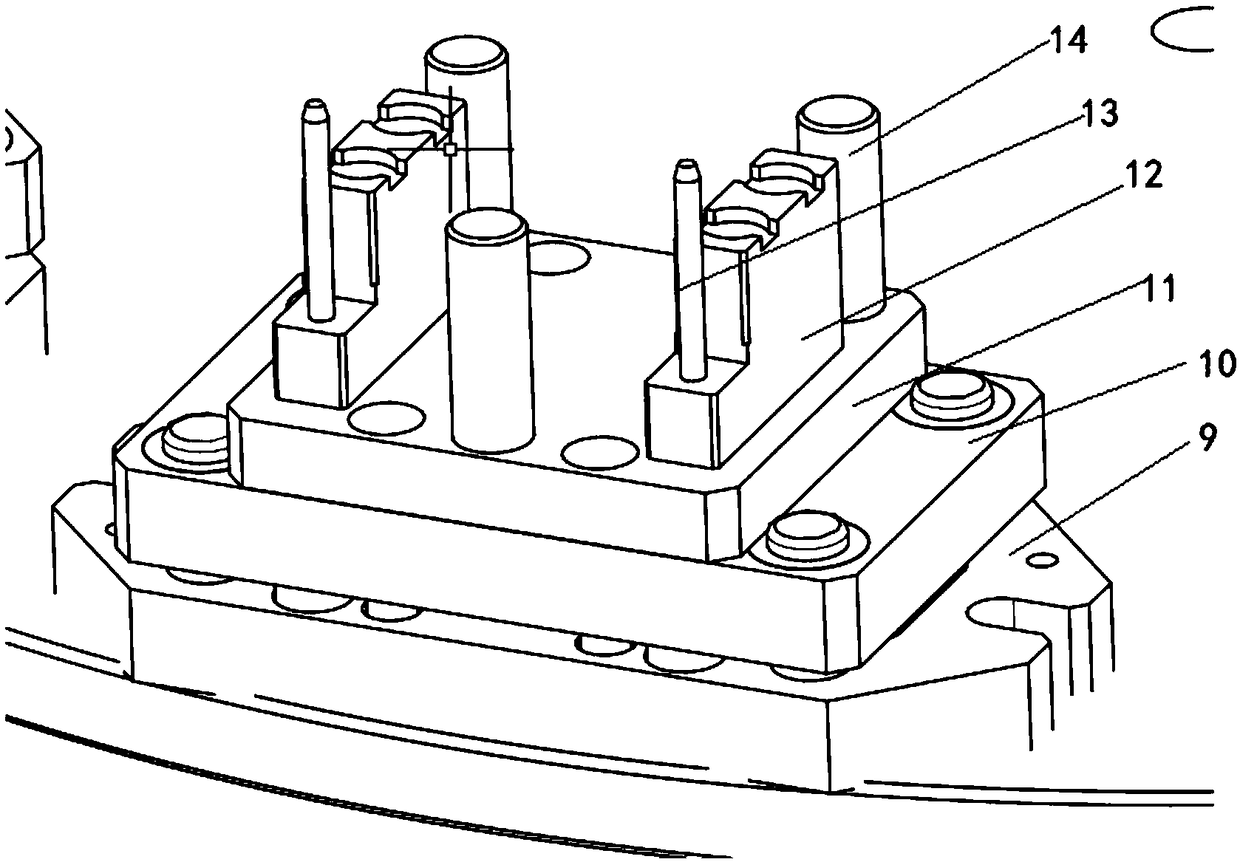

[0022] The clamp 8 includes a clamp connecting plate 9, the clamp connecting plate 9 is a rectangular plate with 45 degree chamfering at four cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com