PDS efficient fly ash stabilizing system

A technology of stabilization treatment and fly ash, applied in the removal of solid waste, etc., can solve the problems of low test pass rate, harsh working environment, corroded equipment, etc., to reduce pollutant concentration, improve working environment, and prevent ammonia. escape effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

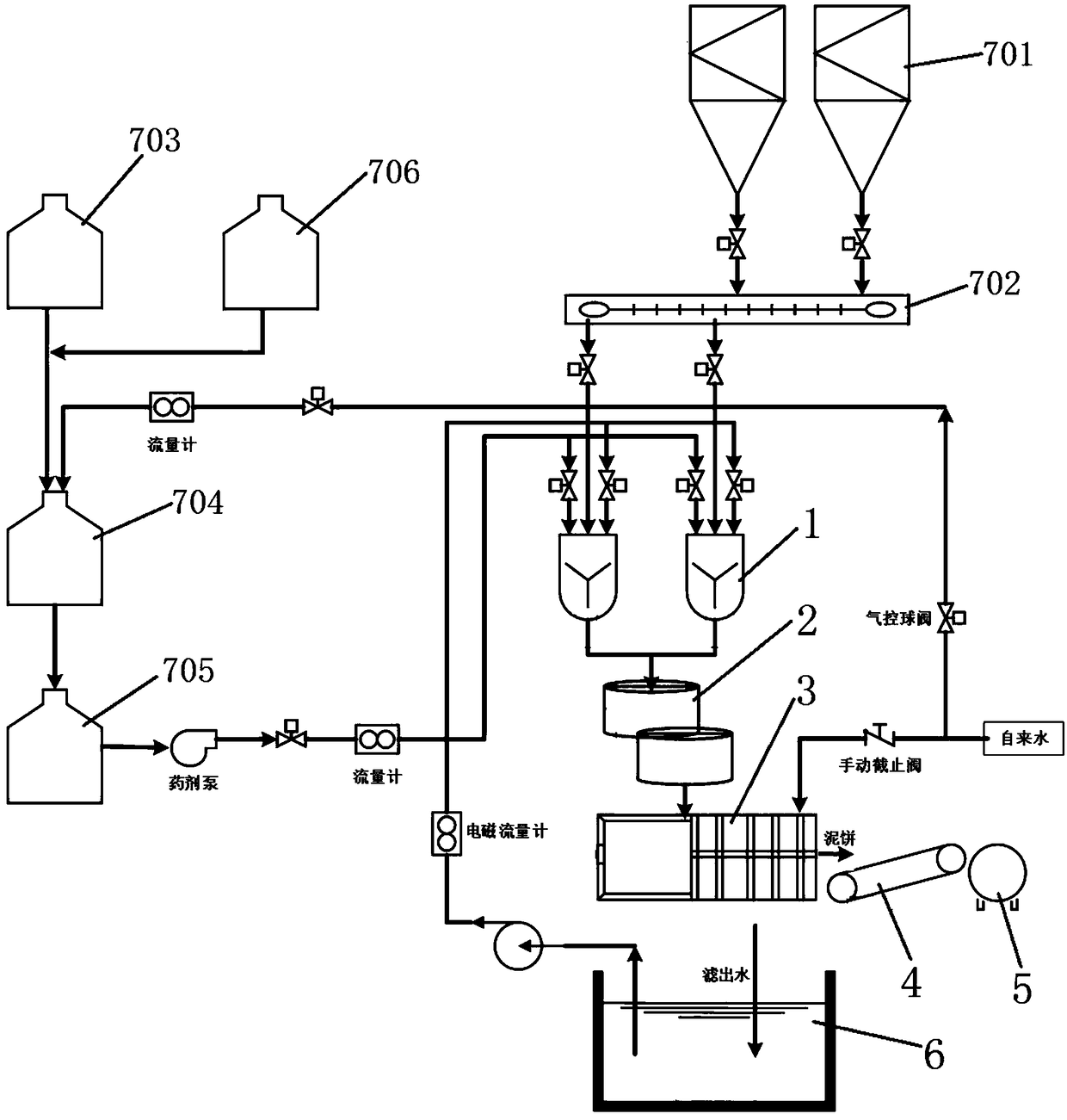

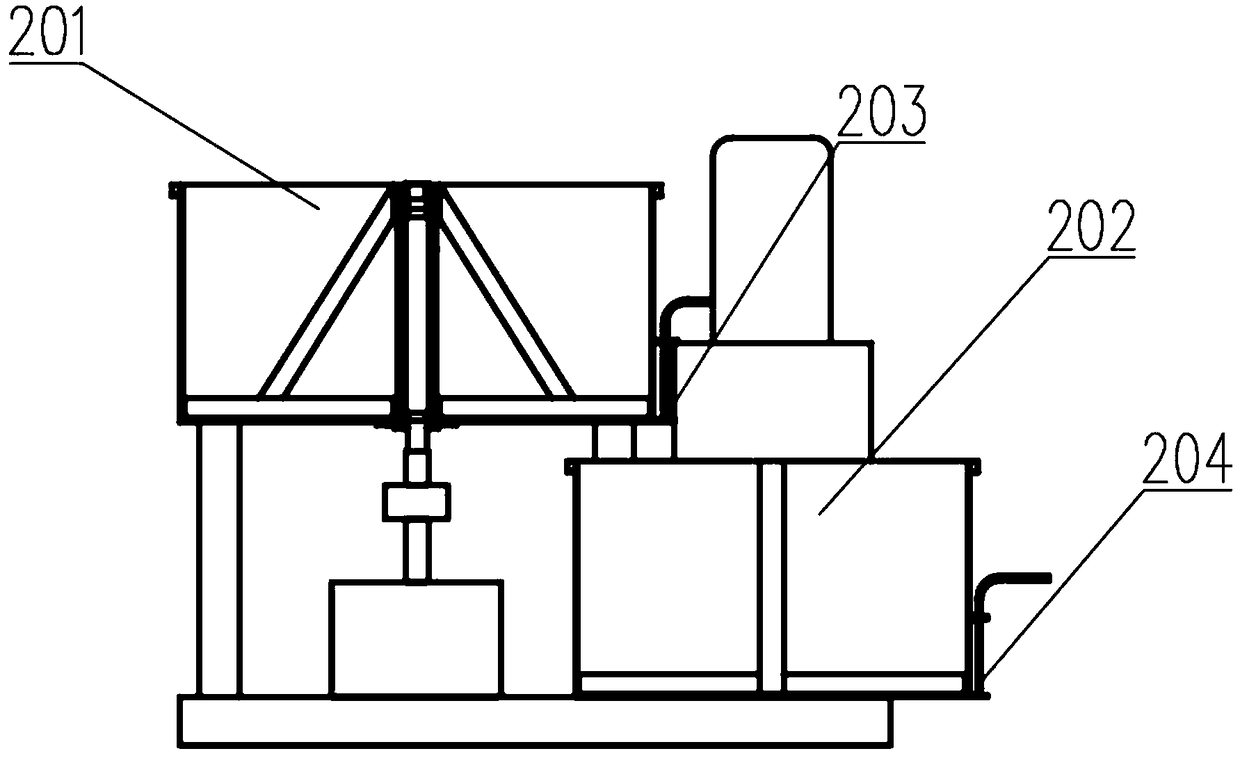

[0026] Such as figure 1 , figure 2 The PDS high-efficiency fly ash stabilization treatment system shown includes a stirring device 1 for mixing raw materials, and the stirring device 1 is connected with a feeding system for feeding the stirring device 1, and the feeding system includes fly ash Feeding system, chelating agent feeding system, water supply system, retarder feeding system.

[0027]Described fly ash feeding system comprises ash bin 701 and scraper machine 702; Described chelating agent feeding system comprises the liquid medicine storage tank 703 that is connected successively, chelating agent preparation tank 704, chelating agent storage tank 705; Described water supply system is Water supply pipeline, described water supply pipeline links to each other with chelating agent preparation tank 704 and stirring equipment 1; Described retarder feeding system comprises retarder storage tank 706, and described retarder storage tank 706 links to each other with chelatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com