High temperature resistance microcapsule beef flavor and preparation method thereof

A beef essence and microcapsule technology, which is applied in the field of food additives, can solve the problems of poor fragrance retention, not soft enough fragrance, and narrow application surface, and achieves the effects of good embedding effect, improved quality and stable quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

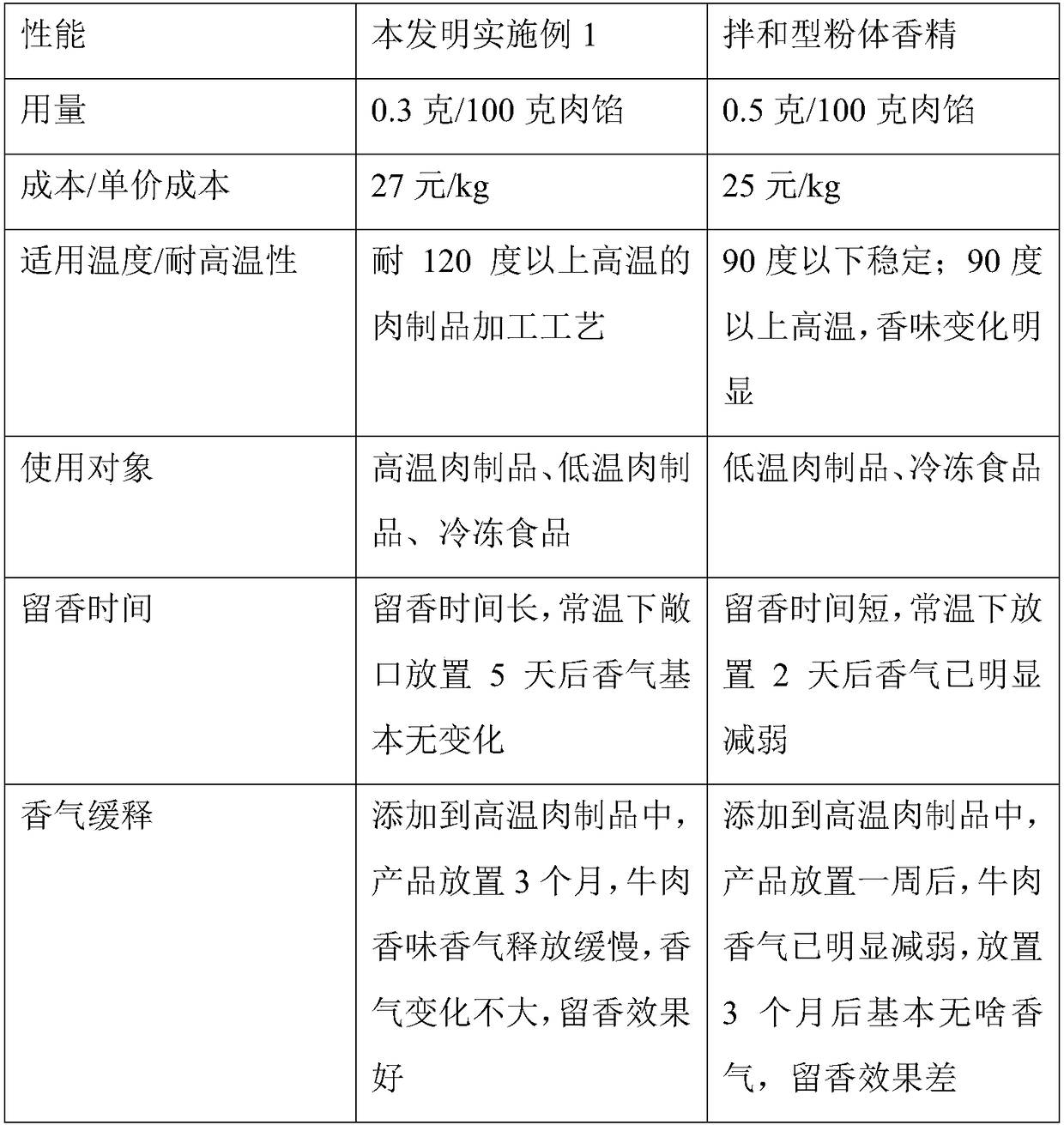

Examples

Embodiment 1

[0024] The beef enzymatic hydrolysis solution is prepared from the following components: 42 parts of beef shank, 0.05 part of compound protease, 0.15 part of flavor protease, 12 parts of table salt and 46 parts of water.

[0025] Wherein, the above-mentioned beef fragrance base is prepared from the following components: 0.5 part of 4-hydroxy-2,5-dimethyl-3(2H) furanone, 1 part of ethyl maltol, 0.3 part of Methylcyclopentenolone, 0.5 parts of 5-hydroxyethyl-4-methyl-thiazole, 0.5 parts of 4-methyl-5-(2-acetoxyethyl)-thiazole, 0.3 parts of cinnamon bark Oleoresin, 2 parts of 1% 2-methyl-3-furanthiol, 7 parts of 1% 3-mercapto-2-butanol, 0.3 parts of tetrahydrothiophen-3-one, 2 parts Concentration of 1% anisaldehyde, 3 parts of 1% 3-methylthiopropanal, 0.4 parts of 3-methylthiopropanol, 3 parts of 1% methyl (2-methyl- 3-furyl)disulfide, 0.8 parts of 1% 2,3,5-trimethylpyrazine, 0.2 parts of octanoic acid, 1 part of 1% 12-methyl-tridecanal and 50 parts of caprylic and capric glyce...

Embodiment 2

[0040] The beef enzymatic hydrolyzate is prepared from the following components: 40 parts of beef, 0.2 parts of compound protease, 0.2 part of flavor protease, 13 parts of salt and 45 parts of water.

[0041]Wherein, the above-mentioned beef fragrance base is prepared from the following components in parts by weight: 0.8 parts of 4-hydroxy-2,5-dimethyl-3(2H) furanone, 4 parts of ethyl maltol, 0.3 parts of Methylcyclopentenolone, 2 parts of 5-hydroxyethyl-4-methyl-thiazole, 1 part of 4-methyl-5-(2-acetoxyethyl)-thiazole, 0.5 parts of cinnamon Leather oil resin, 4 parts of 1% 2-methyl-3-furanthiol, 8 parts of 1% 3-mercapto-2-butanol, 0.6 part of tetrahydrothiophene-3-one, 3 A concentration of 1% anisaldehyde, 2 parts of 1% 3-methylthiopropanal, 0.6 parts of 3-methylthiopropanol, 2 parts of 1% methyl (2-methyl -3-furyl)disulfide, 1 part of 2,3,5-trimethylpyrazine at a concentration of 1%, 0.6 parts of octanoic acid, 6 parts of 12-methyl-tridecanal at a concentration of 1% And 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com