a composite cable

A composite and cable technology, which is applied in the direction of power cables, insulated cables, cables, etc., can solve the problems of lack of integrated composite cables, difficult winding of cable cores, inaccurate positioning, etc., and achieve low processing and manufacturing difficulties, shorten construction period, The effect of avoiding signal interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

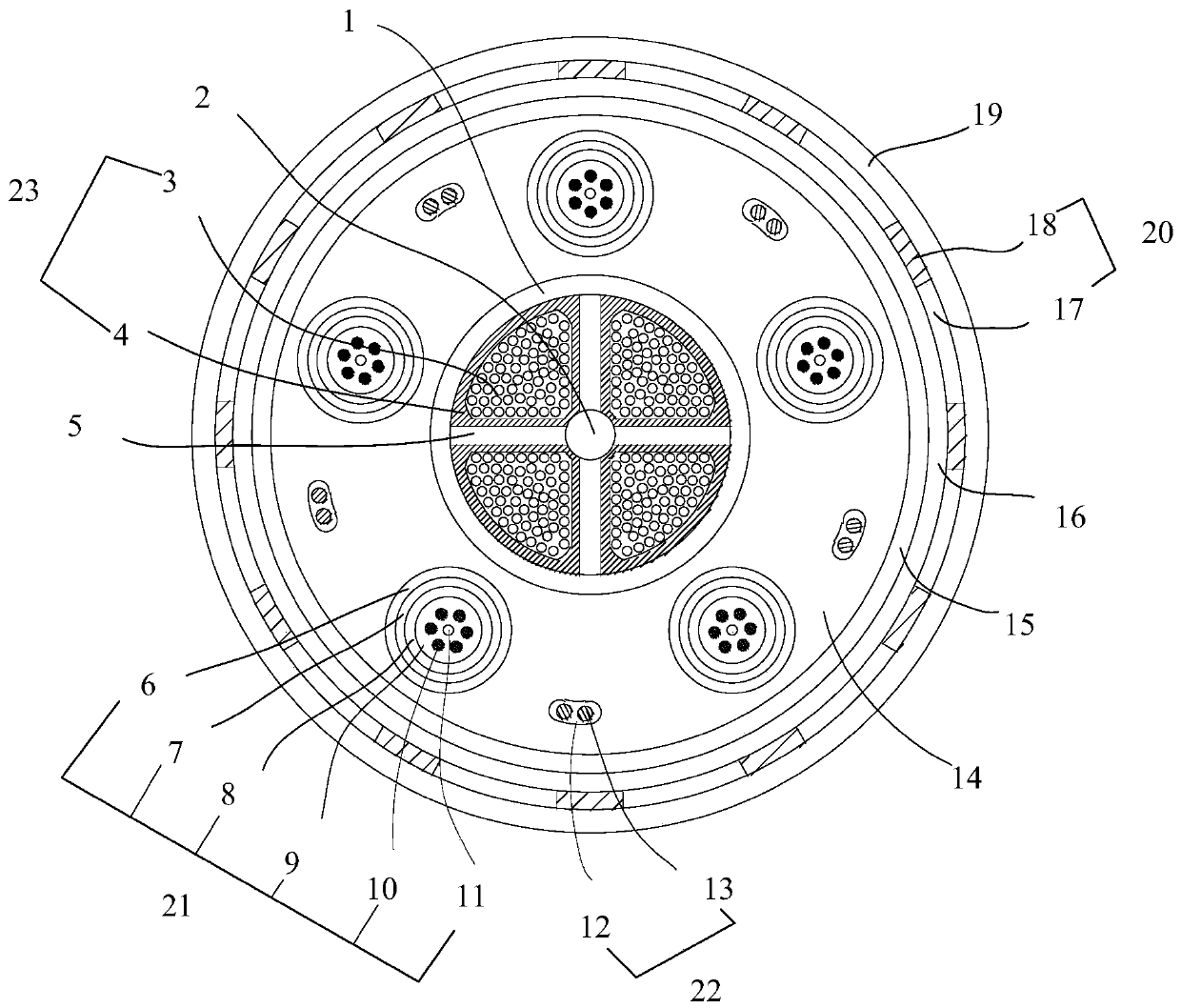

[0029] Such as figure 1 As shown, a composite cable in this embodiment includes: a first strengthening core 2, a plurality of baffles 5, a plurality of conductive cores 23, a first shielding layer 1, a plurality of optical fiber cores 21, a second The shielding layer 15, the cable outer sheath 19 and the first filling layer 14; the outer peripheral side of the first reinforcing core 2 is evenly and fixedly connected with a plurality of baffles 5, and each two adjacent baffles 5 are provided in the cavity formed There is a conductive wire core 23, the first shielding layer 1 is sleeved on the outside of all the baffles 5, the second shielding layer 15 is sleeved on the outer peripheral side of the first shielding lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap