Overhead line system fault identification device and method thereof for electrified railway AT power supply system

A technology for electrified railways and power supply systems, which is applied in the direction of fault location and detection of faults according to conductor types, etc., can solve the problems of difficulty in setting up the catenary sectionalizer nearby, burnt contact wires, burn out contact wires, etc., and reduce the scope of power outages. , Improve reliability and facilitate the effect of old line transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

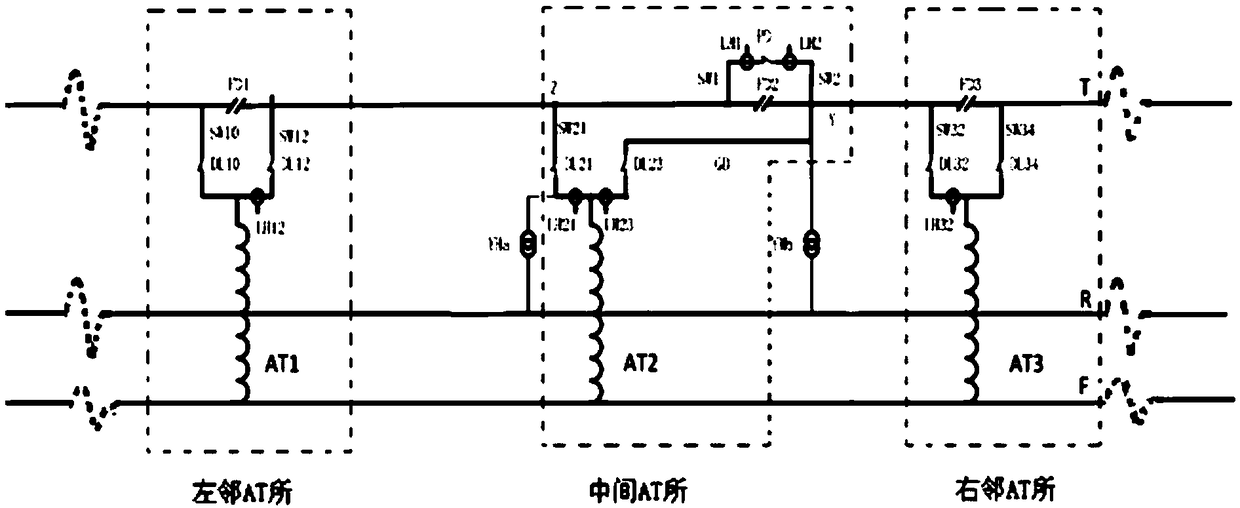

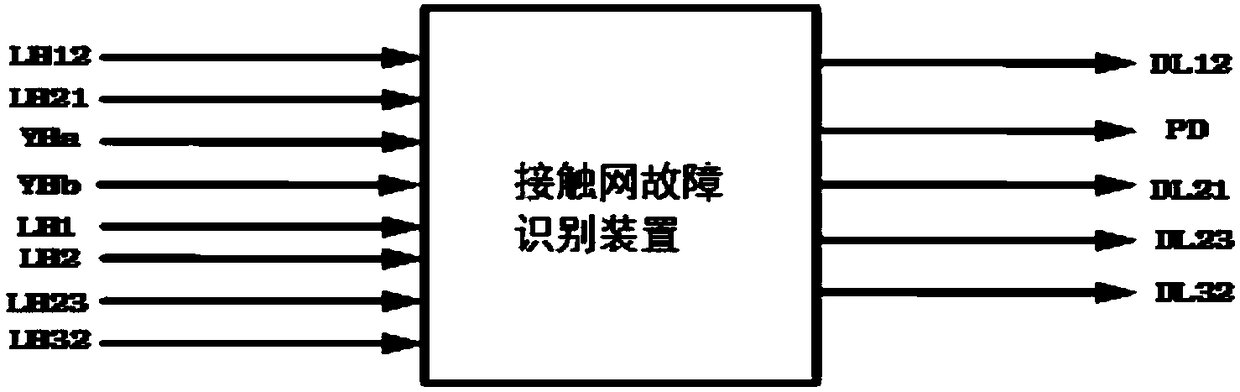

[0026] according to figure 1 and figure 2 As shown, the embodiment of the present invention provides a catenary fault identification device for an AT power supply system of an electrified railway. is an interval, the three AT stations are respectively the left neighbor AT station, the middle AT station and the right neighbor AT station, the fault identification device is arranged in the middle AT station, and the input terminals of the fault recognition device are respectively arranged in parallel with the middle AT station A voltage transformer YHa between the catenary T and the rail R, a voltage transformer YHb installed in parallel between the catenary T where the middle AT is located and the rail R, the left adjacent AT station, and the middle AT The test terminal of the station and the right neighbor AT station is connected, and its output terminal is respectively connected with the control terminals of the left neighbor AT station, the middle AT station and the right n...

Embodiment 2

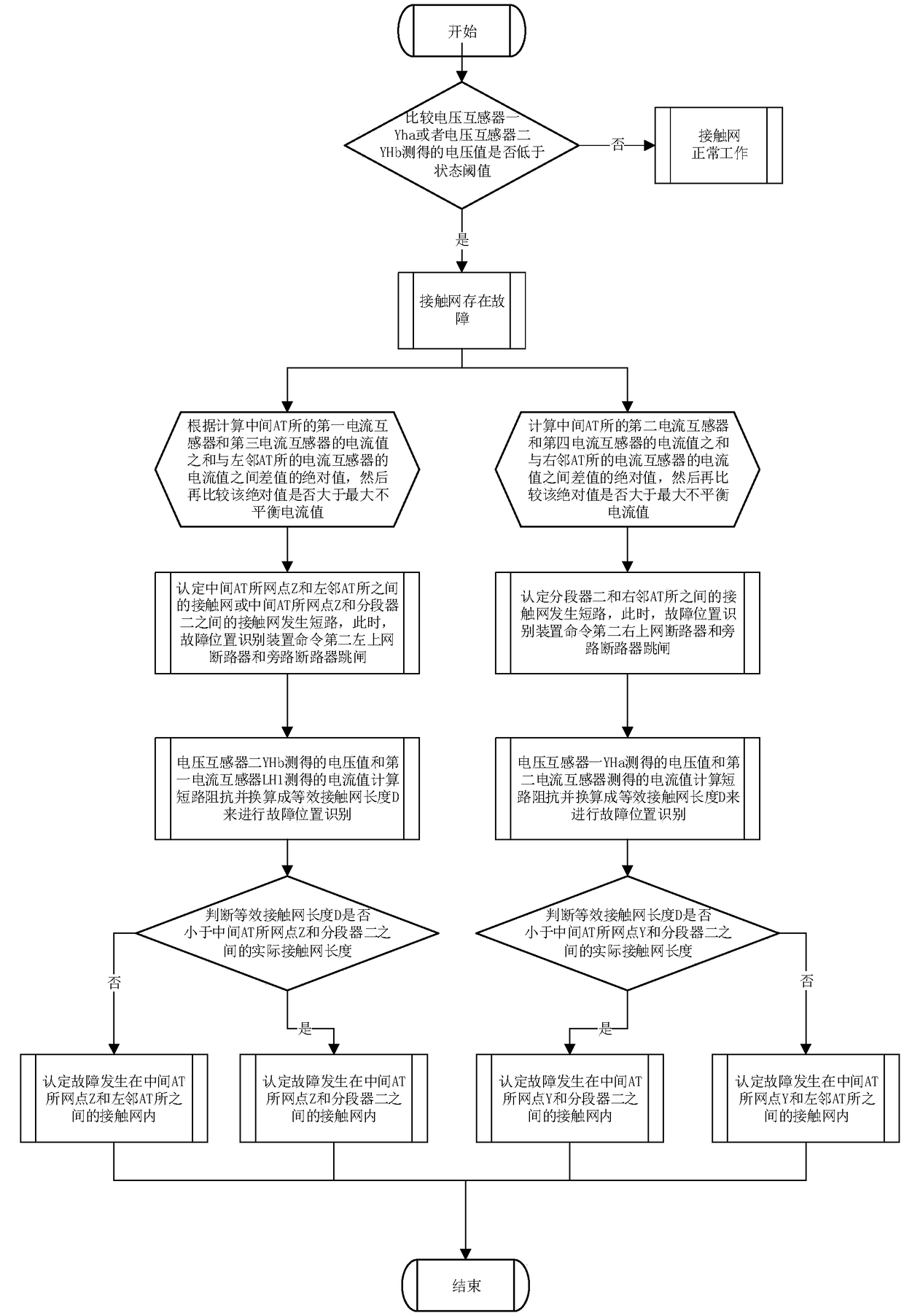

[0035] according to image 3 As shown, the embodiment of the present invention provides a catenary fault identification method for an electrified railway AT power supply system. The specific steps of the catenary fault identification method are as follows:

[0036] Compare the relationship between the voltage value measured by voltage transformer one YHa or voltage transformer two YHb and the state threshold;

[0037] If the voltage measured by voltage transformer 1 YHa or voltage transformer 2 YHb is lower than the state threshold, there is a fault in the catenary of the electrified railway AT power supply system; if the voltage measured by voltage transformer 1 YHa or voltage transformer 2 YHb is equal to or greater than the state threshold, then there is no fault in the catenary of the electrified railway AT power supply system. In the embodiment of the present invention, the state threshold means that the catenary voltage drops to a voltage value that makes the train unab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com