Preparation method of enzyme-labeled antibody

An enzyme-labeled antibody and antibody technology, which is applied to measuring devices, instruments, scientific instruments, etc., to achieve the effects of enhanced stability, low price, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

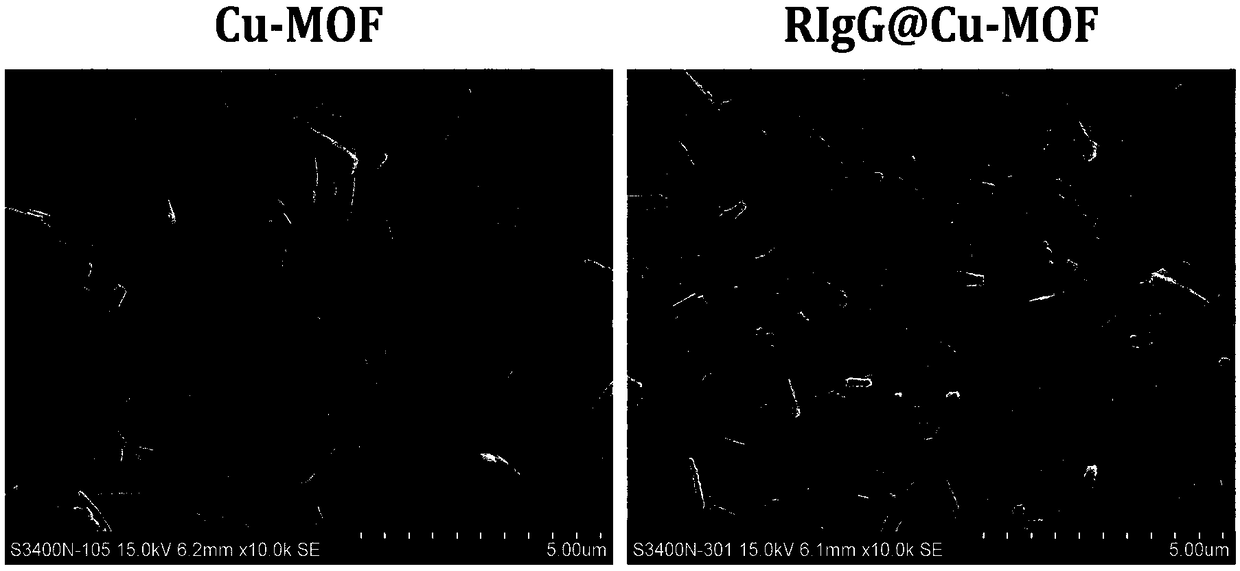

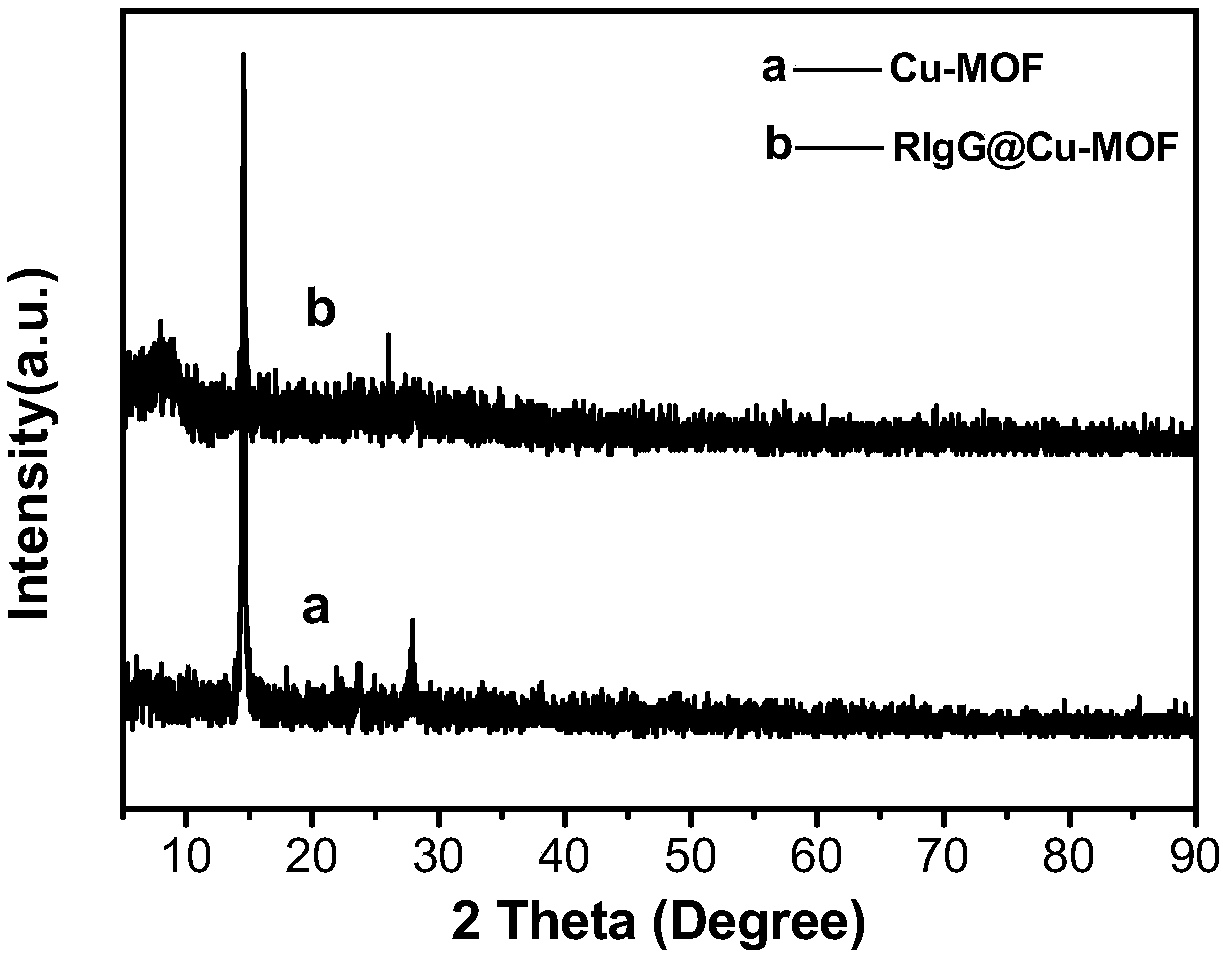

[0027] Follow the steps below to prepare RIgG@Cu-MOF:

[0028] (1) 0.7mg copper chloride dihydrate is dissolved in 1mL water to obtain an aqueous solution of copper chloride dihydrate;

[0029] (2) Mix ethanol and water according to v / v=1:1 to form 1mL ethanol-water mixed solution, and then add 2.4mg 4,4'-bipyridine ligand to obtain 4,4'-bipyridine ligand Ethanol-water mixed solution;

[0030] (3) Mix 1mL copper chloride dihydrate aqueous solution with 1mL ligand ethanol-water mixed solution, add 0.1mg RIgG, stir at 4°C for 12h, centrifuge (13000rpm, 5min), and wash 3 times with water to obtain RIgG@ Cu-MOFs.

Embodiment 2

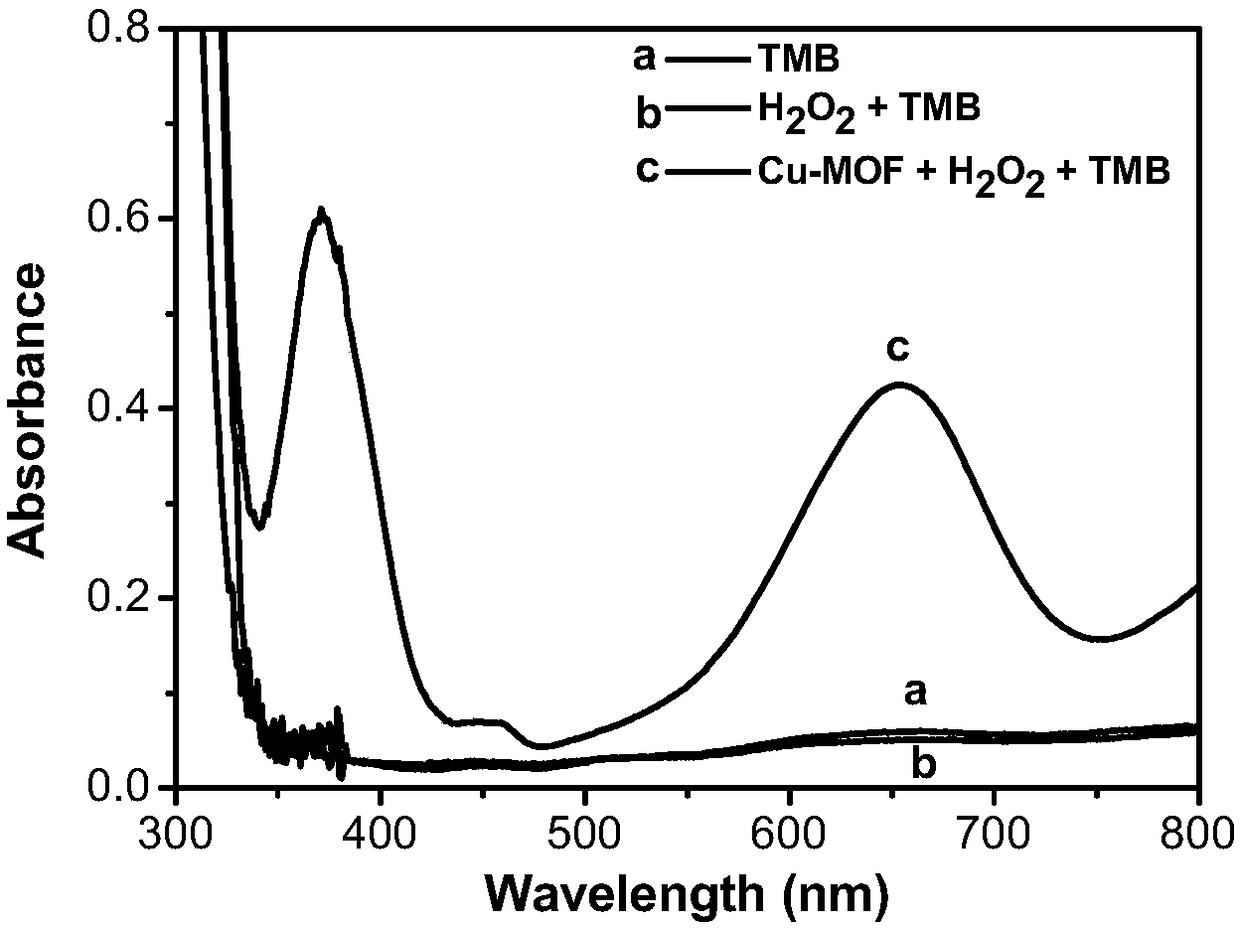

[0032] Combined with the 3,3',5,5'-tetramethylbenzidine (TMB) oxidation experiment, the absorbance corresponding to its maximum absorption peak was recorded by a UV spectrophotometer to prove the simulated enzyme activity of Cu-MOF. Its method steps are:

[0033] (1) Sodium acetate (NaAc) with pH = 4.0 was used as a buffer solution with a total volume of 100 μL and a reaction temperature of 37° C.;

[0034] (2) Use three 0.5mL centrifuge tubes, numbered a, b, and c respectively. The preparation method of the solution in centrifuge tube a is as follows: Take 3 μL of 2 mg / mL 3,3',5,5'-tetramethylbenzidine (TMB) in 97 μL of sodium acetate (NaAc) buffer solution with pH=4.0, and place in a 37°C water bath React for 30 minutes;

[0035] (3) The preparation method of the solution in the centrifuge tube b is: take 3 μL 2mg / mL TMB, 2 μL 100mM hydrogen peroxide H 2 o 2 In 95 μL of sodium acetate (NaAc) buffer solution with pH=4.0, react in a water bath at 37°C for 30 minutes;

[0...

Embodiment 3

[0039] To prove that RIgG@Cu-MOF can recognize mIgG, the solution was prepared in a 96-well plate, and then the absorbance corresponding to the maximum absorption peak was recorded by a UV spectrophotometer. The specific method is:

[0040] (1) Using a 96-well plate, number the reaction wells as a, b, and c respectively, and the reaction wells a, b, and c are respectively coated with buffer solution (carbonate buffer solution with pH=9.6 and a concentration of 0.05 mol / L) Dilute RIgG to a final concentration of 10 μg / mL, react at 4°C for 12 h, wash the reaction wells 4 times with 400 μL of washing buffer (pH=7.4, 0.15 mol / L carbonate buffer containing 0.05% Tween-20), and Remove unfixed RIgG and pour off the washing solution;

[0041] (2) Add 400 μL of blocking agent (washing buffer containing 1% BSA) to reaction wells a, b and c respectively, react at 37°C for 40 min, and wash 3 times;

[0042] (3) Add mIgG with a final concentration of 100ng / mL to reaction wells a, b and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com