Canned bottle leakage detection device

A detection device and canning technology, applied in the direction of using liquid/vacuum degree for liquid tightness measurement, etc., can solve the problems of increasing processing procedures, reducing production efficiency, and prolonging the time required for detection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

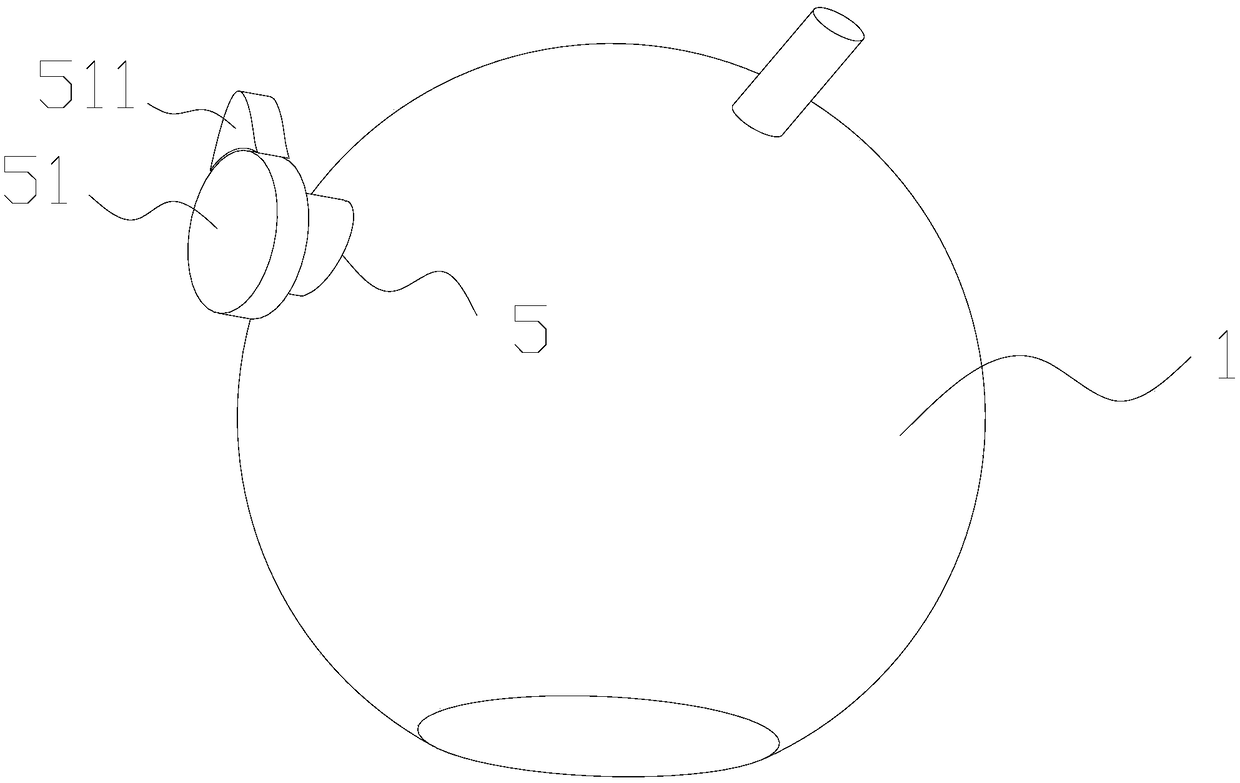

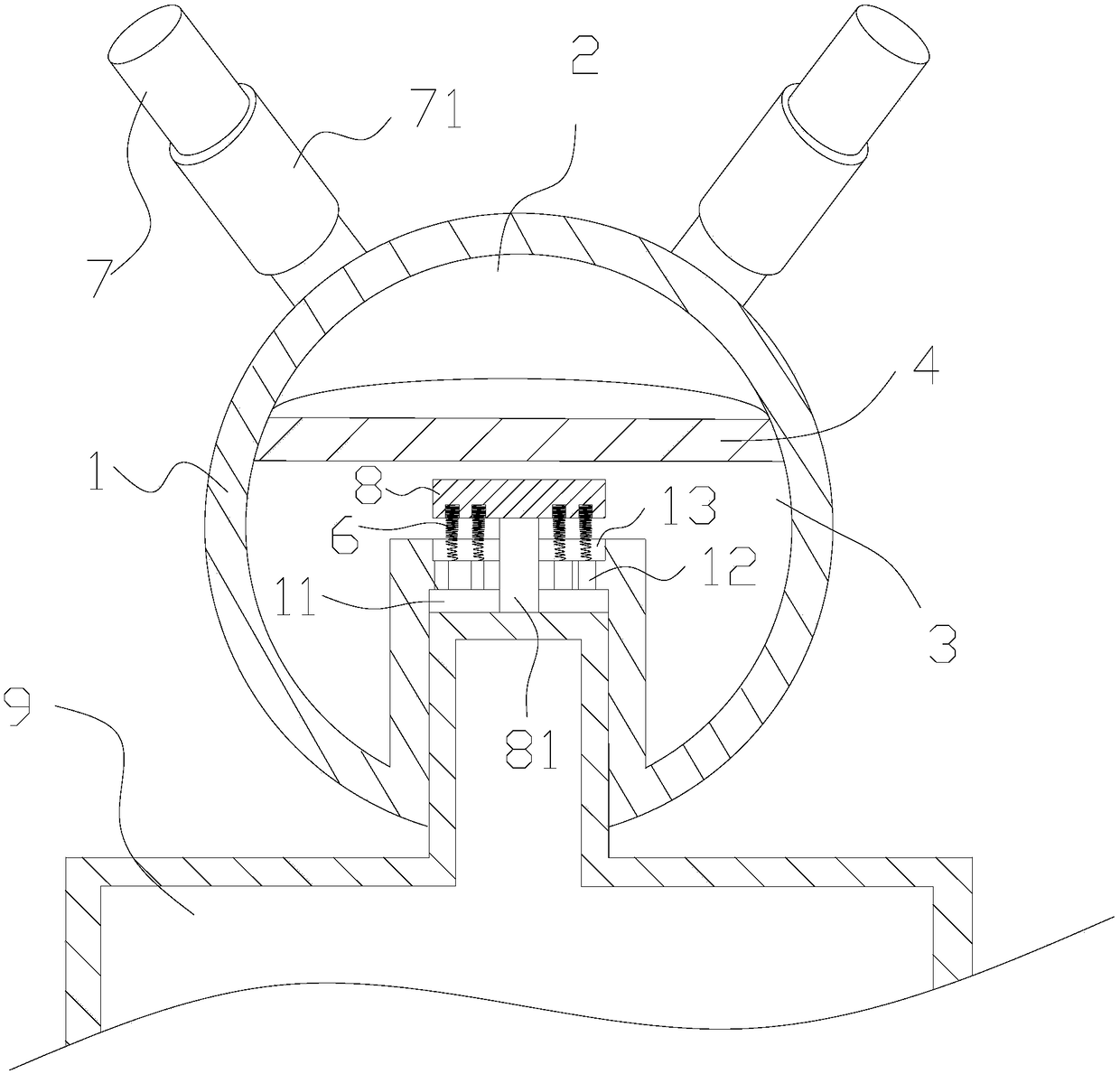

[0019] A canned bottle air leakage detection device, with reference to figure 1 and figure 2 , including a sealed casing 1, and the inside of the casing 1 is set in a vacuum state. The interior of the casing 1 is provided with a gas-permeable membrane 4, and the side of the gas-permeable membrane 4 is fixedly connected with the inner wall of the casing 1. The gas-permeable membrane 4 divides the casing 1 into an air chamber 3 and a detection chamber 2. In this embodiment, the casing 1 The upper end of the housing 1 is the detection chamber 2, and the lower end of the housing 1 is the gas chamber 3. Sodium is placed inside the detection chamber 2. In this embodiment, in order to improve the detection effect, the sodium is pure sodium. Because sodium encounters air, the color will change. Therefore, in order to further improve the observation effect, the inner wall of the detection chamber 2 is coated with a hydrophobic layer, so as to prevent sodium from adhering to the inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com