Diesel engine starting device and method based on cold region operation and paver

A diesel engine and engine starting technology, which is applied to engine components, machines/engines, valve devices, etc., can solve problems such as difficulty in starting and heavy diesel engine load, and achieves the goal of reducing wear, improving air leakage, and reducing resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The present invention is designed with a new type of diesel engine starter for the existing method and the device difficult to meet the operation of the cold zone roller paver, and the operation timing fuel consumption is designed. The engine achieves a simple and reliable start of the cold zone operation by adopting measures such as valve decompression starting devices, piston nano treatment and cylinder gap, and achieves the solid self-lubrication function of the piston while reducing wear, reducing engine oil and diesel consumption. In addition, the apparatus and measures increase cost, the starting current is reduced, extend the life of the start motor and the piston.

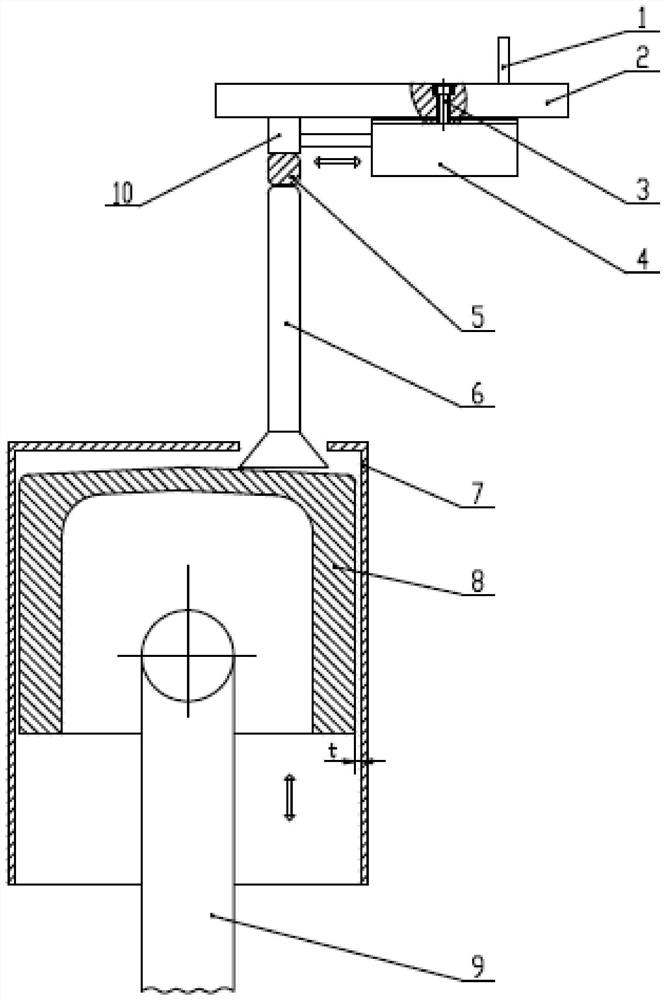

[0027] like figure 1 As shown, the present invention discloses a diesel engine activation device based on the cold zone operation, including a pressure plate 2, a two-way electromagnet 4, a cylinder junction 7, and a valve 6, and the bidirectional electromagnet 4 is connected to the bottom surface of the...

Embodiment 2

[0034] Embodiments of the present application also provide a startup method, which uses the starting device in Example 1, and specifically includes the steps of:

[0035] Step 1, monitor the status and speed of the engine. In this step, monitoring can be monitored by monitoring or by the paver itself by the controller set in the engine.

[0036] Step 2, when the engine is started, the stopper 10 is in the first position to turn the valve 6 to open the reduced start boot.

[0037] Step 3, when the engine speed exceeds the set threshold, the stopper 10 is in the second position so that the valve 6 is turned off to achieve decompression start. In this step, the set threshold of the engine speed is set as needed, which can be set to 250 revolutions, 300 rpm, 350 rot, etc., when the engine starts, the speed will increase rapidly, and the set threshold is preferably rapidly promoted. The minimum of 250 rpm is 250 rpm.

Embodiment 3

[0039] Embodiments of the present application also provide an paver that can take the starting device in Example 1. The paver can be well implemented in the cold zone, saving oil and fuel consumption during construction work, extend the life of the piston and starting the motor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com