A sub-channel flow sampling device and method

A sampling device and channel flow technology, applied in the field of sampling, can solve problems such as difficulty in implementation, difficulty in ensuring the accuracy of measurement results, etc., and achieve the effects of low cost, easy processing and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in detail:

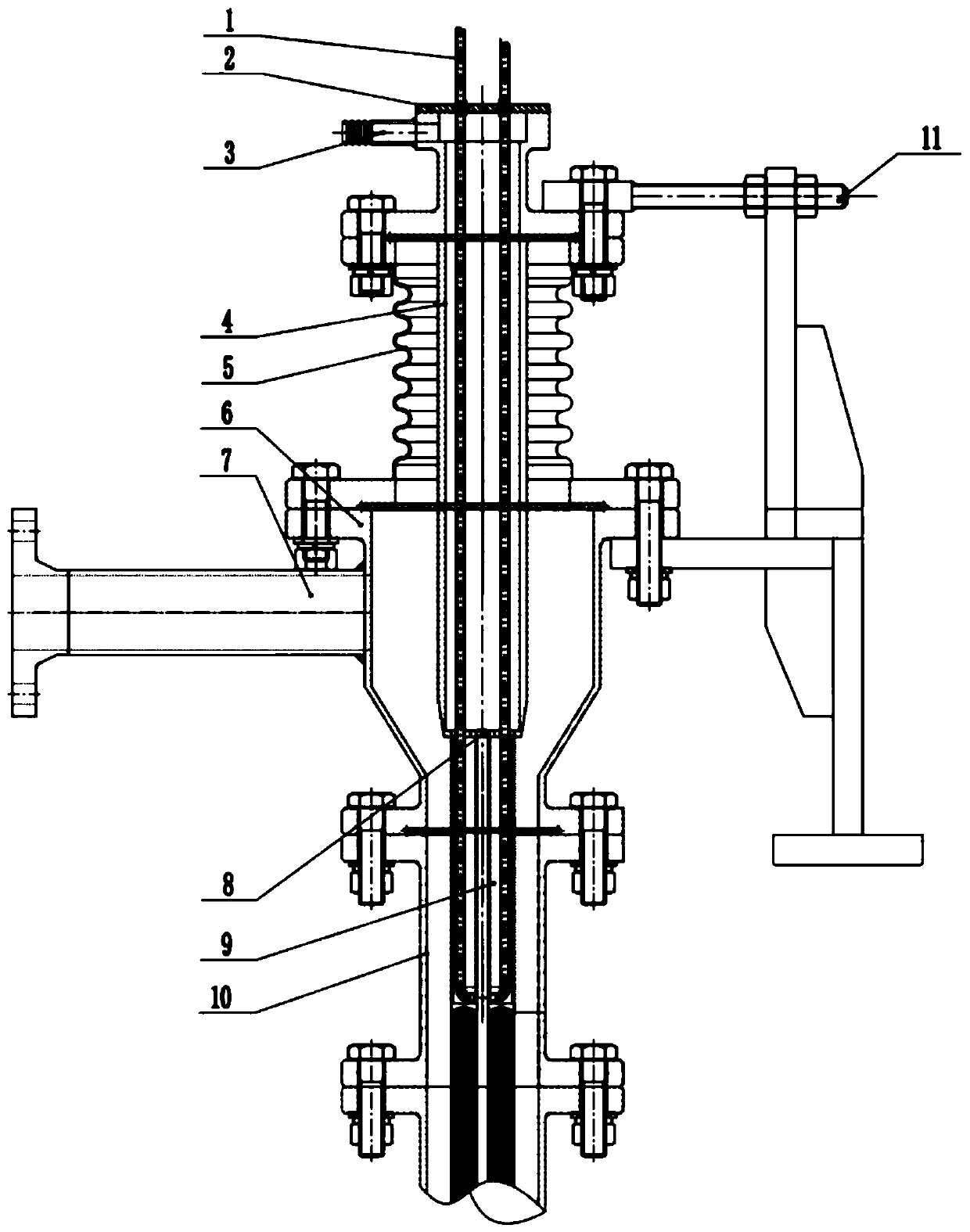

[0024] Such as figure 1 As shown, a sub-channel flow sampling device of the present invention, the flow sampling device is based on the principle of isokinetic sampling, including a pressure introduction tube 1, a cover 2 on the sampling flow channel, a sampling section outlet connecting pipe 3, and a circular cross-section sampling flow channel 4. Flexible bellows 5, upper chamber 6, upper chamber outlet connection 7, lower cover of sampling channel 8, sampling probe 9, visualization pipe section 10, and adjustment device 11.

[0025] The sampling probe 9 is located at the lower part of the entire flow sampling device for extracting the sub-channel flow, and the pressure introduction tube 1 is located inside the sampling probe 9 and welded with the inner tube wall of the sampling probe; the pressure introduction tube 1 is drawn through the inside of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com