Automobile bearing self-control oil injection device

An oil injection device and a technology for automobile bearings, which are applied in the direction of lubricating oil input, lubricating parts, mechanical equipment, etc., can solve problems such as failure to meet precision requirements, waste, and affect bearing life, and achieve fast and convenient placement of bearings and low production costs , high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

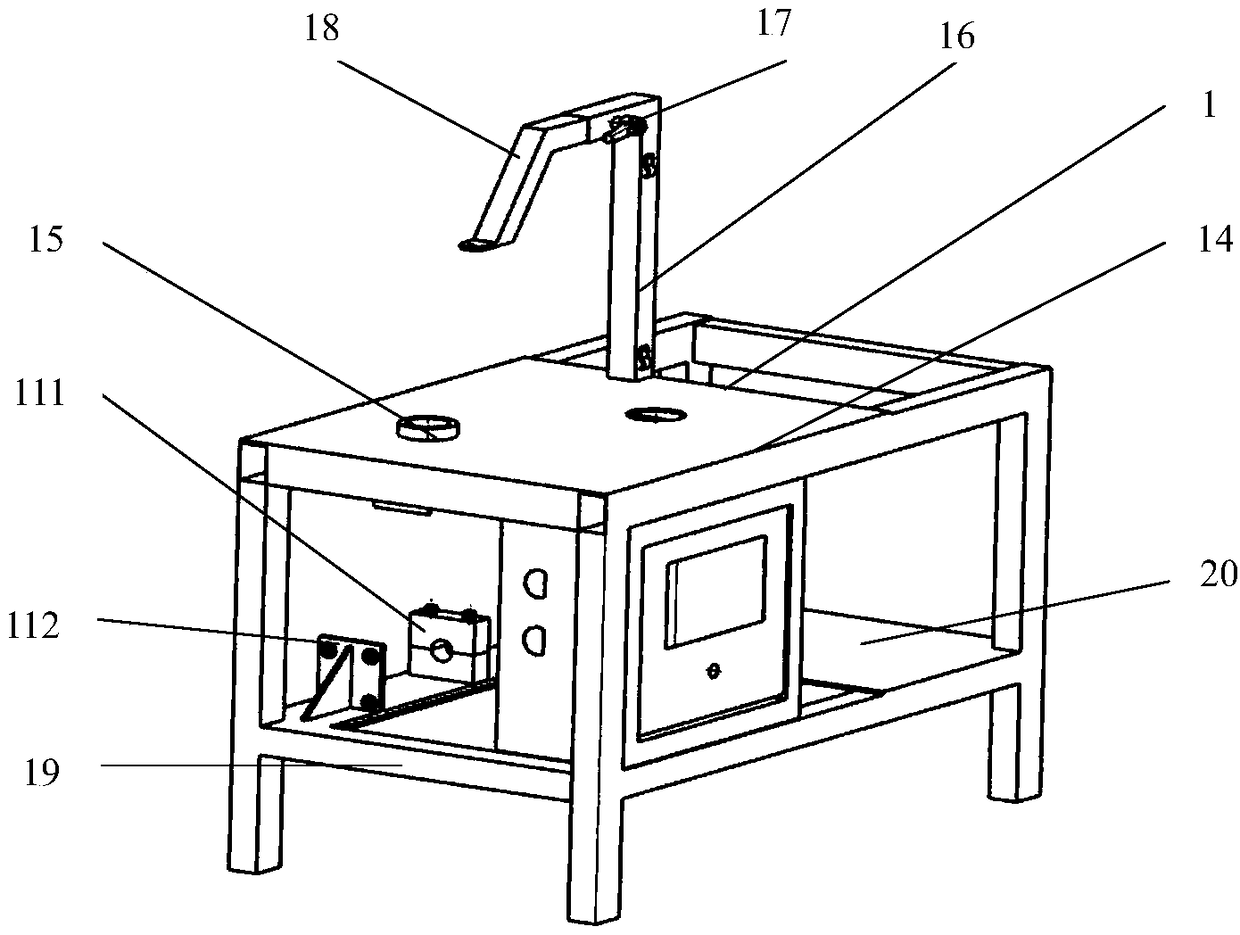

[0025] The implementation process of the oil injector of the present invention is described in detail in conjunction with the accompanying drawings. Such as Figure 1-Figure 6 As shown, a self-control oiling device for automobile bearings includes a frame 1, and the frame 1 is composed of a workbench 14, an oil injection support rod 16, an oil injection arm 18, a support handle 19, a pipeline support plate 111, and a cylinder backing plate 112. The oil injection arm Tightening handle 17 is housed on it, and the length of arm can be adjusted so as to adjust the horizontal distance between grease nipple 29 and bearing 44. One side of the frame 1 is provided with an oil drum placement hole, and the oil drum 21 is supported by the support plate 20; the other side is provided with a bearing 44 fixing hole, and the bearing 44 is fixed by the rotating shaft 45 and the conical pressure plate 43, and the installation steps under the workbench The motor 5 is connected to the bearing 44...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com