Intelligent pre-stress inhaul cable nut and pre-stress monitoring method

A cable nut and prestressing technology, applied in force/torque/work measuring instruments, measuring devices, instruments, etc., can solve the problems that the steel strand cannot truly reflect the force of the cable body, and the measurement and installation process is cumbersome and time-consuming. , to achieve the effect of saving measurement and installation time, saving measurement security, and convenient use and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] This embodiment provides an intelligent prestressed cable nut;

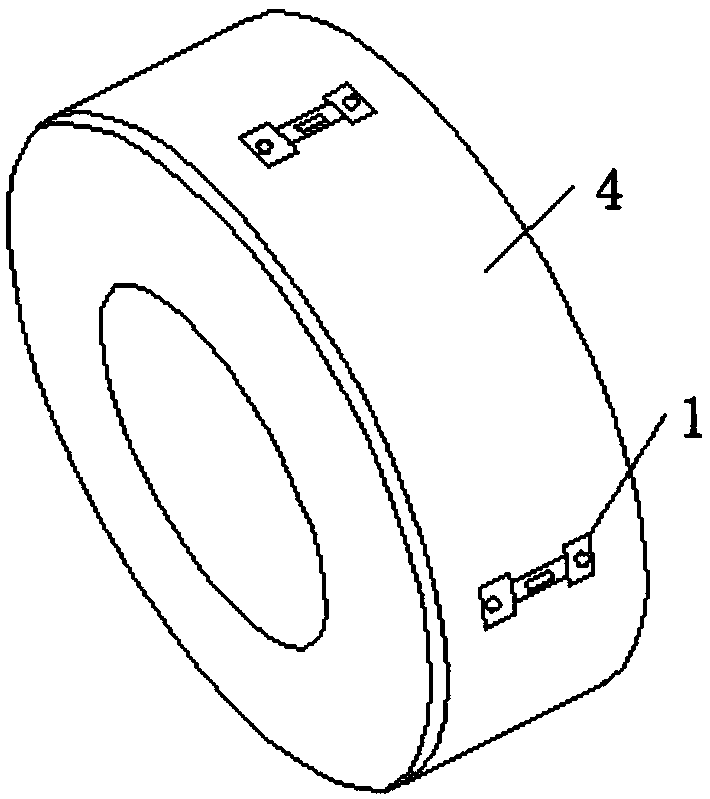

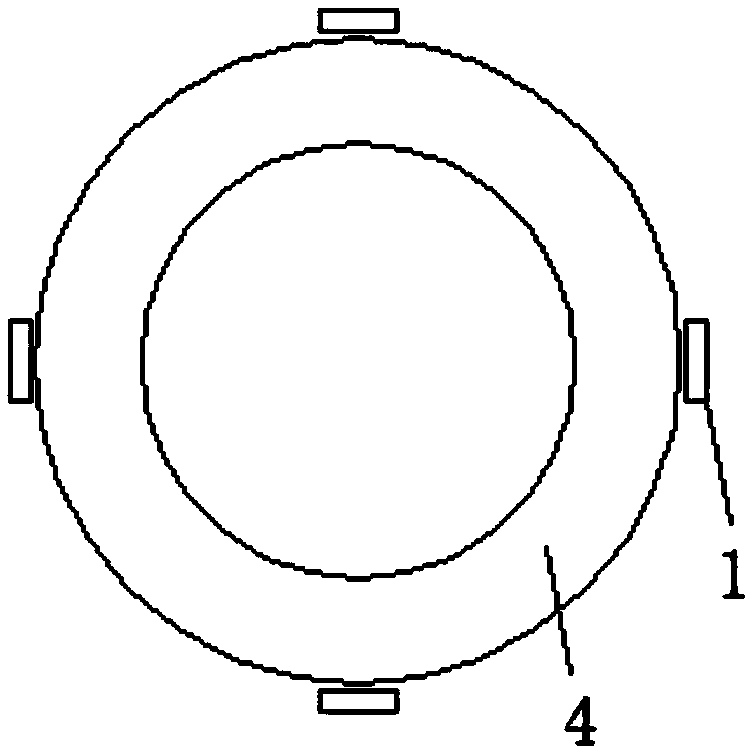

[0041] Such as figure 1 and figure 2 As shown, the intelligent prestressed cable nut in this embodiment includes a cable nut 4, and a plurality of strain sensors are arranged on the cable nut 4, and the strain sensor includes a measuring section that is deformed consistently with the cable nut 1 and the sensitive element 2 located on the measuring section 1.

[0042] In the present invention, a plurality of strain sensors are arranged on the cable nut, and the strain sensor includes a measuring section which deforms consistently with the cable nut and a sensitive element arranged on the measuring section. After the cable body is anchored, all the steel strands are subjected to The force will be transmitted to the prestressed cable nut. Through the integrated design of the sensor and the cable nut, the cable nut can be monitored to obtain the force status of the cable body. Compared with the existing steel...

Embodiment 2

[0044] This embodiment provides a strain sensor;

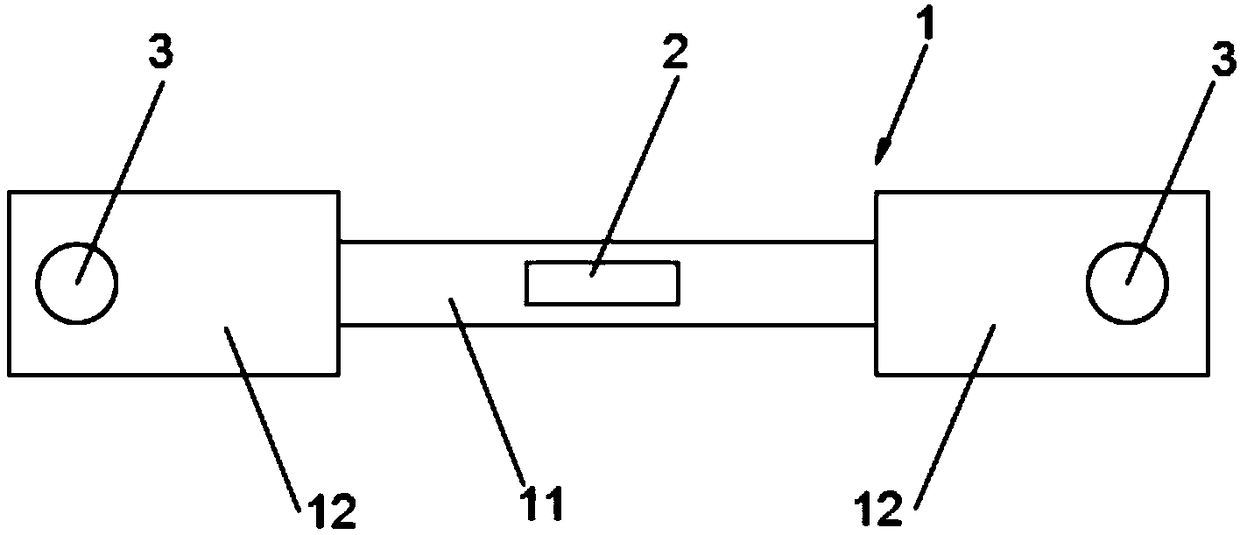

[0045] The strain sensor in this embodiment includes a measuring section 1 that produces consistent deformation with the cable nut and a sensitive element 2 that is arranged on the measuring section 1. The measuring section 1 includes a first measuring section 11 and a second measuring section 12. On a cross-section perpendicular to the tension direction of the cable nut, the cross-sectional area of the first measuring section 11 is smaller than the cross-sectional area of the second measuring section 12 .

[0046] By setting the measuring section to include the first measuring section and the second measuring section, and on the section perpendicular to the force direction of the cable nut, the cross-sectional area of the first measuring section is smaller than that of the second measuring section, when the cable When the nut is deformed, the strains of the first measurement section and the second measurement section ar...

Embodiment 3

[0058] This embodiment provides an intelligent prestressed cable nut;

[0059] Such as Figure 1-Figure 3 As shown, the intelligent prestressed cable nut in this embodiment includes a cable nut 4, and a plurality of strain sensors are arranged on the cable nut, and the strain sensor includes a measuring section that is deformed consistently with the cable nut 4 1 and the sensitive element 2 located on the measuring section 1.

[0060] In the present invention, a plurality of strain sensors are arranged on the cable nut, and the strain sensor includes a measuring section which deforms consistently with the cable nut and a sensitive element arranged on the measuring section. After the cable body is anchored, all the steel strands are subjected to The force will be transmitted to the prestressed cable nut. Through the integrated design of the sensor and the cable nut, the cable nut can be monitored to obtain the force status of the cable body. Compared with the existing steel st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com