Body Fatigue Test Device and Test Method

A fatigue test and vehicle body technology, applied in the field of vehicle testing, can solve the problems of single loading and stress, cumbersome loading process, prolonging the test cycle, etc., achieve high accuracy and reliability, improve test accuracy, and shorten the test cycle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

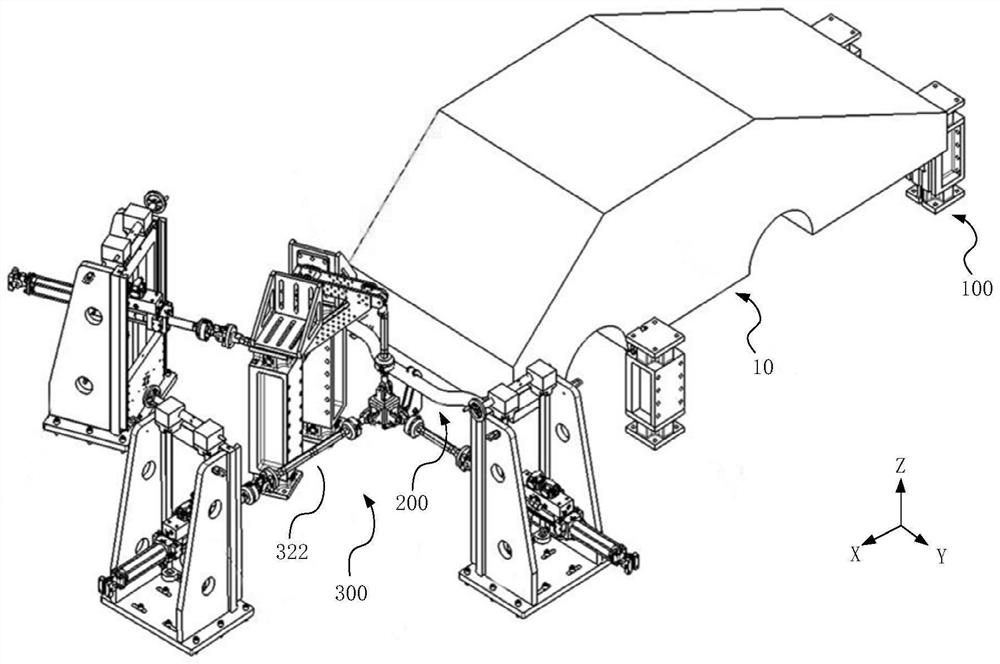

[0050] At present, most vehicle fatigue gantry tests are still limited to the use of equal load spectrum loading, but due to its single-load force, it is unable to reflect the true force of the road, which will result in unable to obtain reliable test results, and also extend Whole test cycle. The traditional road analog load spectrum of the gantry test device not only carries the process of cumbersome, but also the design of the structure of the traditional loading test device and the transmission path of the loading power, it is not possible to achieve the purpose of the truth, so that the test is not guaranteed. The accuracy and reliability of the results.

[0051] In addition, with the continuous improvement of the vehicle structure, the devices and test systems in the gantry trial also put forward higher requirements. In particular, most vehicles in China have not set up traction mechanisms, only in special cases, if they need to pull or drag the vehicle or items, they need t...

Embodiment 2

[0072] The present invention also provides a body fatigue test method, at least the steps of:

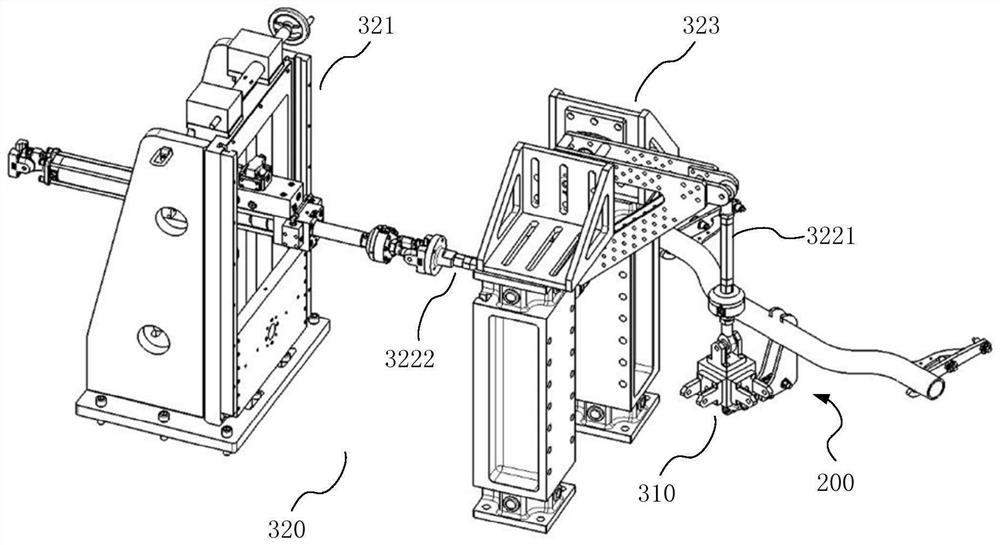

[0073] The first end of the fixed body 10 is fixed to the constraint mechanism 100;

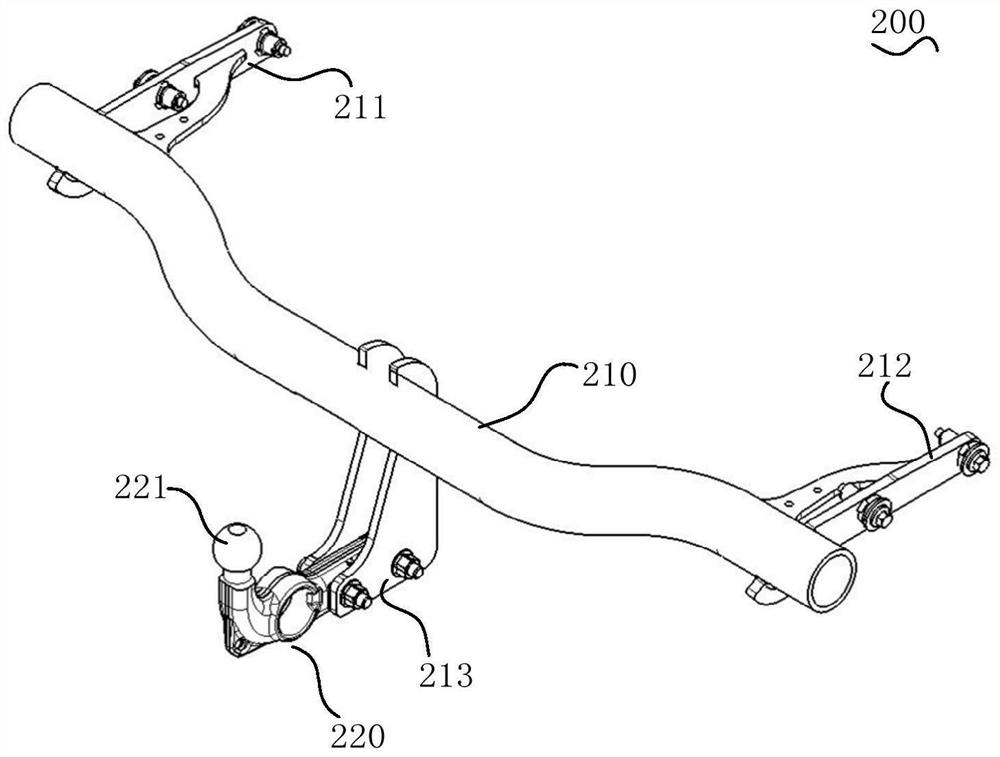

[0074] The two end portions of the transition member 210 in the transition mechanism 200 are connected to both sides of the second end of the vehicle body 10, and the end of the hinged member 220 in the transition mechanism 200 is connected to the non-end portion of the transition member 210, and adjusts the corresponding Torque;

[0075] According to the preset load spectrum, the adjustment load mechanism 300 treats the loading load of the test body 10, and hinges the loading mechanism 300 to the other end of the hinged piece 220 in the transition mechanism 200, respectively;

[0076] The final drive signal is obtained according to the preset loading spectrum, and the fatigue test is performed.

[0077] Next, the fatigue test of the rear end of the white car body is tested as an example, and the body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com