A steel pipe tower climbing ladder auxiliary device and its installation method

An auxiliary device, the technology of tower climbing ladder, applied in the direction of ladders, buildings, building structures, etc., can solve the problems of inconvenient transportation, handling and storage, inability to flexibly adjust the height, and inability to realize stable connection, etc. Simple, volume-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

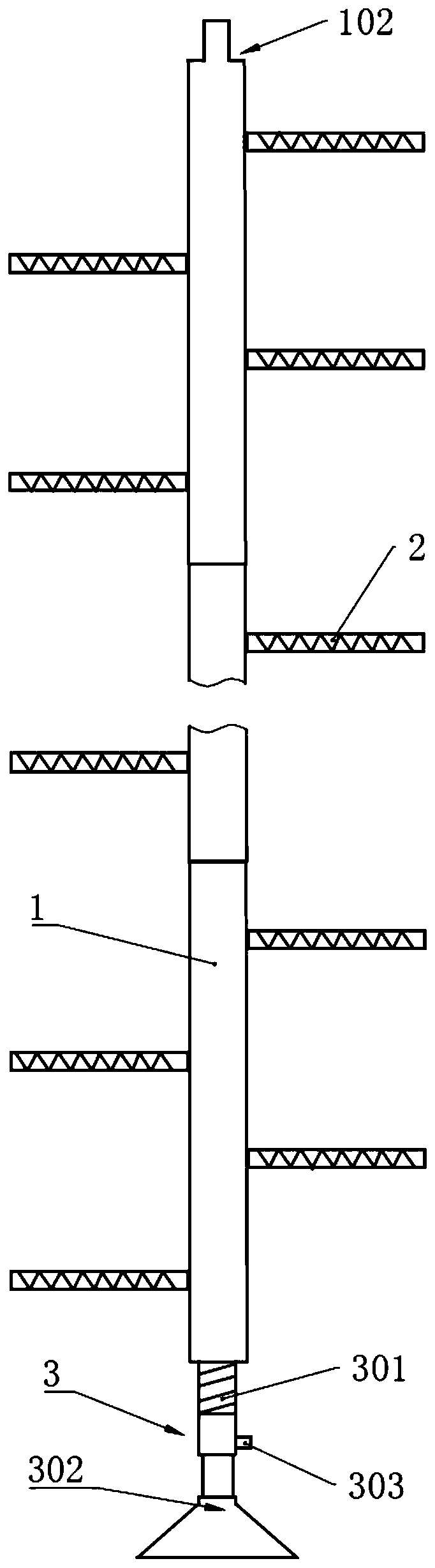

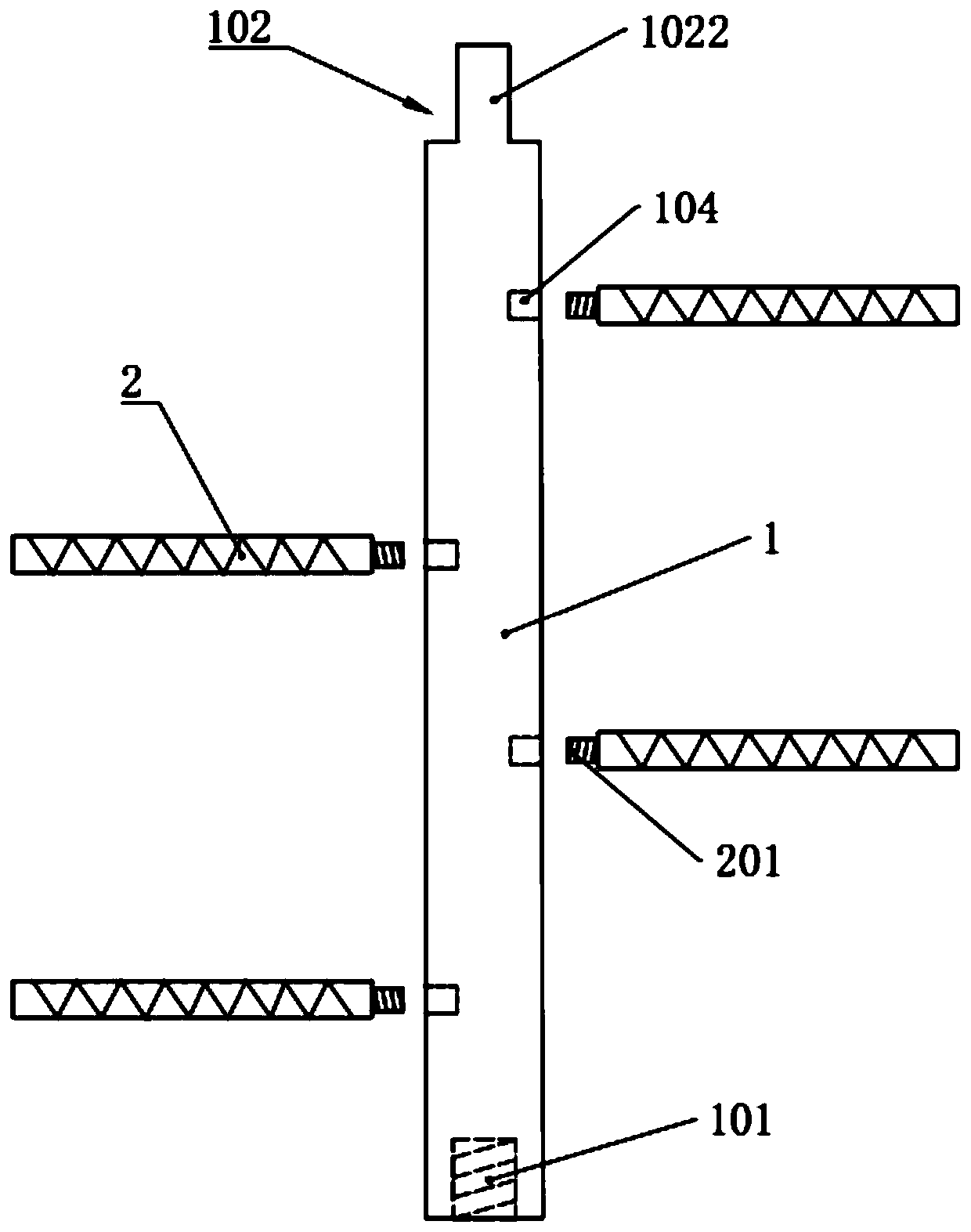

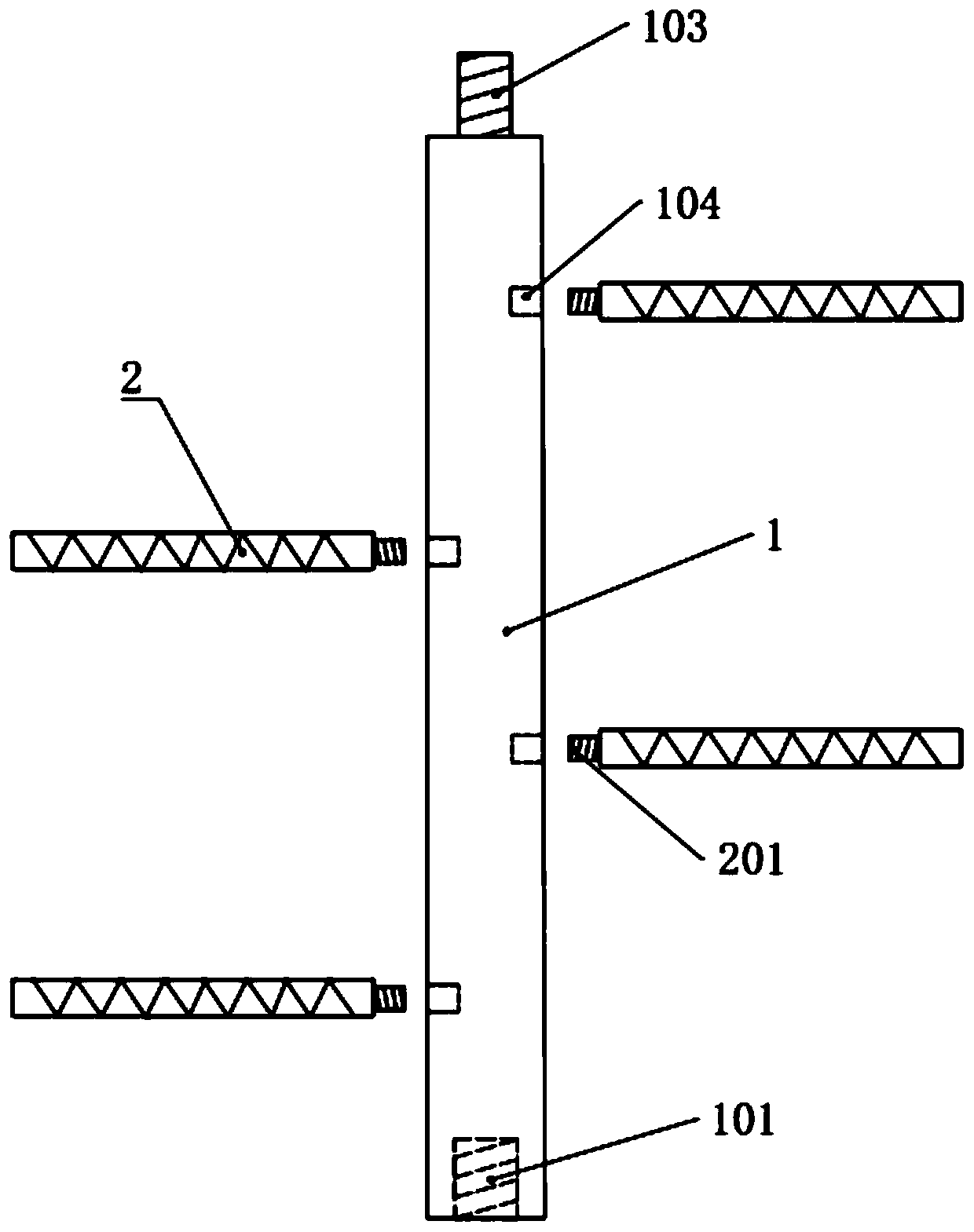

[0046] like Figure 1 to Figure 3 As shown, the present embodiment provides a steel pipe tower ladder climbing auxiliary device, including a ladder bar 1, anti-skid spikes 2 and a lifting base 3; Threaded holes 101, wherein the top of one ladder rod 1 is provided with a fastening part 102 for realizing connection with the bottom of the ladder 4, and the tops of the other ladder rods 1 are provided with first screw rods 103 compatible with the first threaded hole 101 , the ladder rods are connected to each other through the first screw rod 103 and the first threaded hole 101.

[0047] In this embodiment, the ladder bar 1 can be artificially divided into two types according to the structure of the above ladder bar 1 . like figure 2 As shown, a clamping support rod with a clamping part 102 on the top is provided, and one is connected to the uppermost end of the device during use to realize the clamping connection with the steel pipe tower ladder 4; image 3 Shown, another kin...

Embodiment 2

[0060] like Figure 7 As shown, the structure of this embodiment is the same as that of Embodiment 1, the difference is that the clamping part 102 includes two correspondingly arranged limiting rods 1024, both of which are L-shaped, and one end is fixedly welded to the ladder bar 1 Above, the welding point is set lower than the top of the ladder bar 1, and the top of the welded stop bar 1024 is set higher than the top of the ladder bar 1. When in use, the foot nail at the bottom of the ladder 4 is stuck between the stop bar 1024 and the ladder bar 1 The clamping part 102 is provided in the limiting gap, which is simple in structure, convenient in manufacture and strong in practicability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com