Heat preservation decoration integrated wall board for fabricated building

A prefabricated, wall panel technology, applied in the direction of walls, building components, buildings, etc., can solve the problems of unstable adhesive material performance, complex processing and compounding process, poor thermal insulation of metal layers, etc. Application prospects, effects that are not easy to be separated from

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

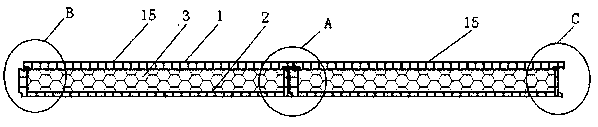

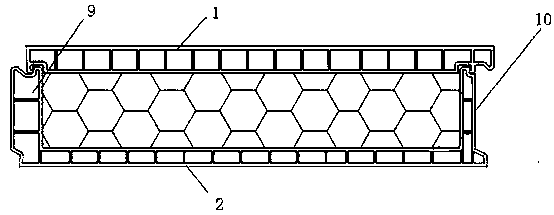

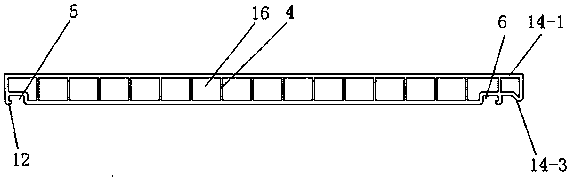

[0038] see Figure 1-7 , the present invention provides an integrated wall panel for thermal insulation and decoration of a prefabricated house, comprising an outer panel 1, an inner panel 2, an insulating material I3, a spacer bar I4, a left lock groove I5, a right lock groove I6, a left lock head I7, a right Lock head I8, left connector 9, right connector 10, upper lap surface I11, lower lap surface I12, left connection groove 13, right connection groove 14, upper boss 14-1, lower boss 14- 2. Barb 14-3, wall panel unit 15, cavity I16.

[0039] Installation and connection relationship: The integrated wall panel for thermal insulation and decoration of the prefabricated house in this embodiment is assembled by a plurality of wall panel units 15 through tongue and groove. The wall panel unit 15 includes an outer panel 1, an inner panel 2, and The insulation material I3 between the outer panel 1 and the inner panel 2, the insulation material I3 is polyurethane or rock wool and ...

Embodiment 2

[0045] The difference between this embodiment and Embodiment 1 is that the outer plate 1 and the inner plate 2 are of solid structure, and the connecting parts include a left connecting part 9 and a right connecting part 10. Part 9, the lock groove of the right connecting part 10.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com