Method for producing after-ripening plum wine

A technology of green plum wine and green plum, which is applied in the field of wine making, can solve the problems of bitterness and heavy taste of green plum wine, achieve the effects of strong fruity aroma, thick taste, and reduce the loss of aroma substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] (4) The preparation method of fruit wine yeast liquid culture fluid:

[0046] The cultivation method of the fruit wine liquid yeast liquid is formed by expanding and cultivating step by step in the order of solid inclined test tubes, liquid test tubes and liquid triangular flasks.

[0047] The culture method of solid inclined test tube bacteria is as follows: use 12 to 13 0 Bx malt juice agar medium, cultivated at 28-30°C for 3 days.

[0048] The preparation method of the medium for seed culture in liquid test tubes and liquid triangular flasks is as follows: soak the rice and steam the rice, add water according to the mass ratio of rice to water 1:2, lower the temperature to 60°C, and use 70-140 units / gram of rice Add glucoamylase, stir evenly, keep warm and saccharify at 58-60°C for 4-6 hours, stir once every hour during this period, filter, and adjust the sugar content to 12-13 0 Bx, adjust the pH to 3.8-4.1 with lactic acid, put it into a 25×200mm test tube and a ...

Embodiment 1

[0051] 1. Preparation of post-ripened greengage: Remove the stalks of fresh greengage, spread it on the ground covered with food-grade plastic film indoors, avoid direct sunlight during the post-ripening period, and wash it gently when the greengage is completely yellow and slightly red. dry to use;

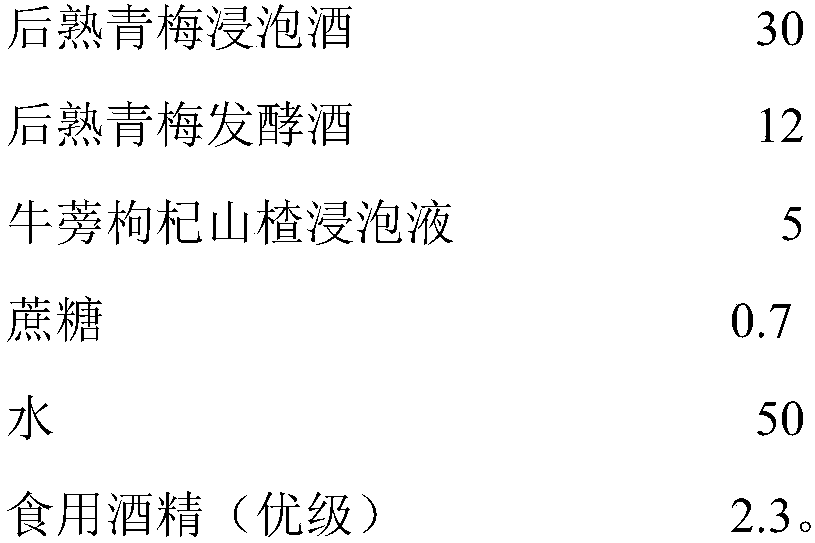

[0052] Two, after preparing ripe green plum soaked wine: dilute edible alcohol (superior grade) to 35% vol with water, add the ratio of above-mentioned ripe green plum 50Kg, sucrose 20Kg by 35% vol edible alcohol 100Kg and soak for 6 months, after filtering and separating to obtain Ripe greengage is soaked in wine for subsequent use; described soaking operation, first put edible alcohol and sucrose, then put greengage, to play buffering effect, prevent after ripe greengage from breaking;

[0053] 3. Prepare burdock, medlar and hawthorn soaking liquid: dilute edible alcohol (superior grade) to 30% vol with water, add 100Kg of 30% vol edible alcohol to soak 6Kg of dried burdock roo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com