Method for removing peculiar smell in capsicum oleoresin

A technology of capsicum oleoresin and odor, which is applied in the field of removing peculiar smell in capsicum oleoresin, which can solve problems affecting product quality, unpleasant rancid smell, and affecting sales price, so as to improve the quality of final products, enhance product competitiveness, and deodorize Obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

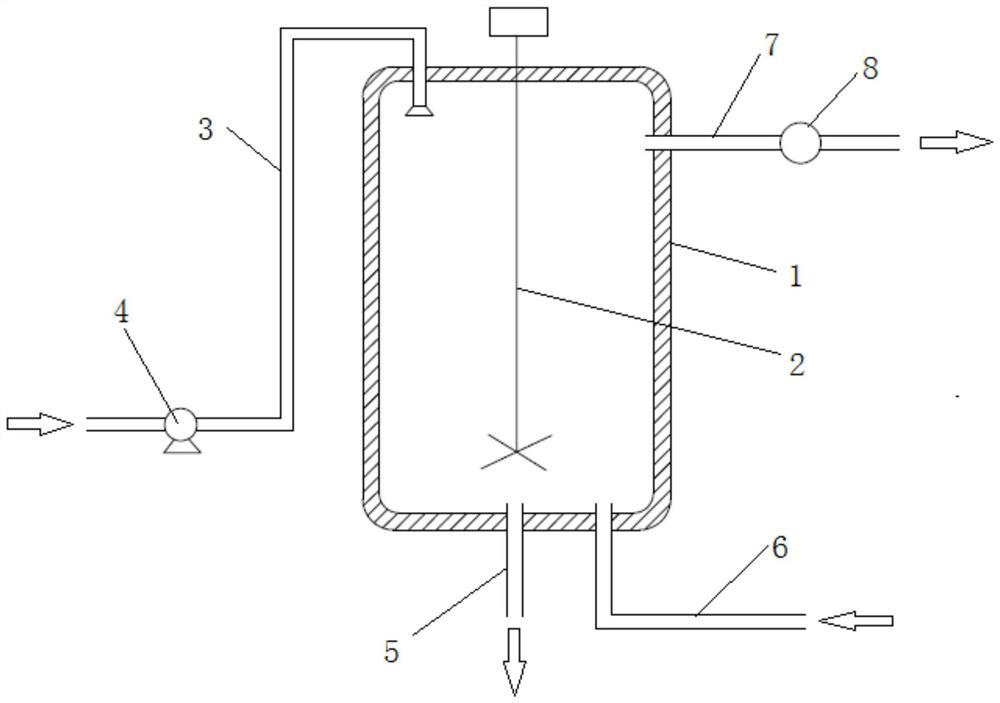

[0022] Preheat the deodorizing tank to 60°C, pump 500kg of capsicum oleoresin into the deodorizing tank 1, add 20kg of ethanol, turn on the agitator 2, heat the capsicum oleoresin to reach a temperature of 100°C, and stir the equipment at a certain speed Capsicum oleoresin, slowly open the vacuum pump 8, when the vacuum degree in the tank is less than -0.02Mpa, slowly open the inlet valve on the high-purity nitrogen delivery pipe 6 below, during which high-purity nitrogen is introduced from below, with a flow rate of 6m 3 / h, keep the temperature in the tank at 120°C, and deodorize for 5 hours. The peculiar smell is taken away by high-purity nitrogen and discharged from the upper outlet pipe 7, which can basically remove the peculiar smell. After completion, the capsicum oleoresin is discharged from the discharge pipe 5.

Embodiment 2

[0024] Preheat the deodorizing tank to 60°C, pump 500kg of capsicum oleoresin into the deodorizing tank 1, add 20kg of ethanol, turn on the agitator 2, heat the capsicum oleoresin to reach a temperature of 100°C, and stir the equipment at a certain speed Capsicum oleoresin, slowly open the vacuum pump 8, when the vacuum degree in the tank is less than -0.02Mpa, slowly open the inlet valve on the high-purity nitrogen delivery pipe 6 below, during which high-purity nitrogen is introduced from below, with a flow rate of 10m 3 / h, keep the temperature in the tank at 130°C, and deodorize for 4 hours. The peculiar smell is taken away by high-purity nitrogen and discharged from the upper outlet pipe 7, which can basically remove the peculiar smell. After completion, the capsicum oleoresin is discharged from the discharge pipe 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com