Composition and preparation method for preparing cross-linked graft copolymer for preventing flying dust and spontaneous combustion of coal storage stacks

A technology of cross-linking, branching and spontaneous combustion, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of unsatisfactory dust suppression effect, difficult degradation of raw materials, and less dust suppressant, and achieve good water retention effect, absorption and swelling Good effect of preventing dust and spontaneous ignition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

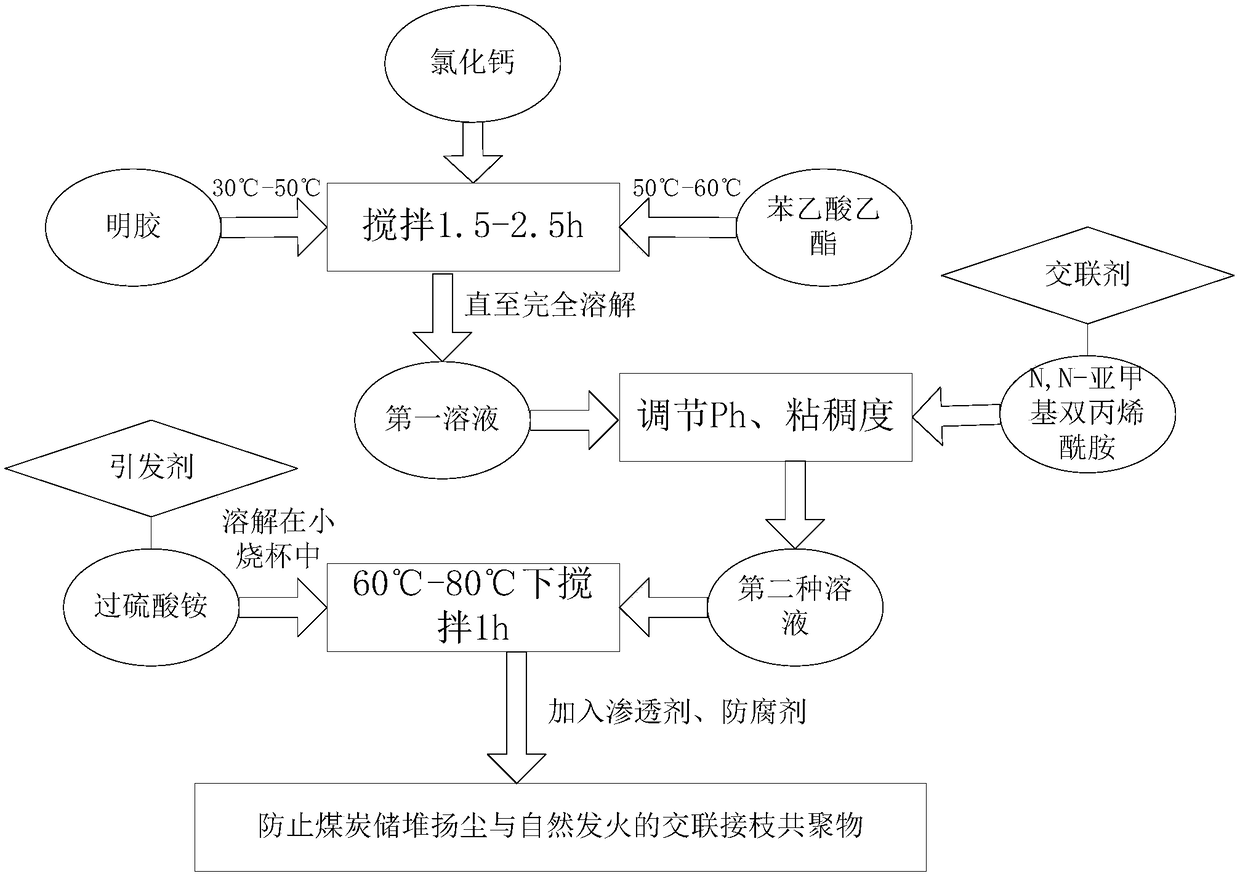

[0028] The present invention also provides a kind of preparation method of above-mentioned cross-linked graft copolymer, such as figure 1 As shown, it includes the following steps:

[0029] Step 1: Stir and dissolve the gelatin in warm water at 30-50°C, mix the inorganic salt solution into the solution and stir for ten minutes, then add ethyl phenylacetate and cross-linking agent to the solution and stir at 50-60°C for 1.5 Hour-2.5 hours, obtain the first solution;

[0030]

[0031] Step 2, adjust the pH value of the first solution, the final product is difficult to dissolve in water, adjust the amount and viscosity of the final product by adding an appropriate amount of water in the reaction stage, and obtain the second solution;

[0032] Step 3: Add N,N-dimethylformamide and initiator to the second solution, set the DF-1 constant temperature stirrer at 60-80°C and stir for 1-2 hours, then add Penetrant and preservative obtain above-mentioned cross-linked graft copolymer...

Embodiment 1

[0036] Weigh 2g of gelatin in warm water as a solvent, then add 0.15g of calcium chloride for stirring, then add 4g of ethyl phenylacetate and 0.04g of N-N methylenebisacrylamide, dissolve in 100ml of water, and react at a constant temperature at 50°C 2h; After the reaction, increase the water content of the solution to 300ml, adjust the pH value to 8; then add 4g of N,N-dimethylformamide, 0.6g of ammonium persulfate, and react at a constant temperature of 70°C After 3 hours, the cross-linked grafted product was obtained, and 0.4 ml of castor oil polyoxyethylene ether sulfonate and 0.2 ml of alkyl dimethyl benzyl ammonium chloride were added to the product, stirred and cooled before use.

Embodiment 2

[0038] Weigh 2g of gelatin in warm water, then add 0.15g of calcium chloride for stirring, then add 5g of ethyl phenylacetate and 0.04g of N-N methylenebisacrylamide, dissolve in 100ml of water, and react at a constant temperature at 50°C 2h; After the reaction, increase the water content of the solution to 300ml, adjust the pH value to 8; then add 4g of N,N-dimethylformamide, 0.6g of ammonium persulfate, and react at a constant temperature of 70°C After 3 hours, the cross-linked grafted product was obtained, and 0.4 ml of castor oil polyoxyethylene ether sulfonate and 0.2 ml of alkyl dimethyl benzyl ammonium chloride were added to the product, stirred and cooled before use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com