PET copolymer containing non-planar ring and preparation method

A copolymer and non-planar technology, which is applied in the field of non-planar ring-containing PET copolymers and its preparation, can solve the problems of insufficient performance of PET materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

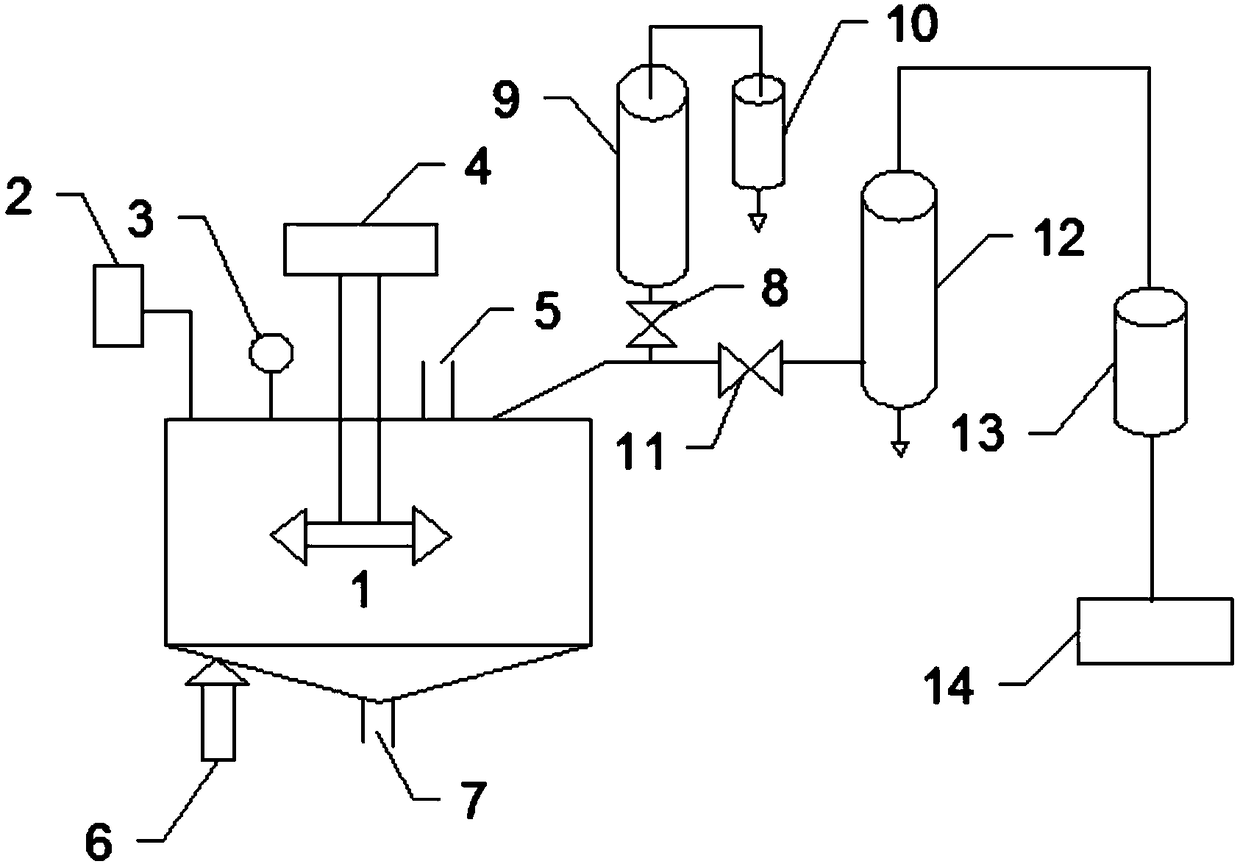

Method used

Image

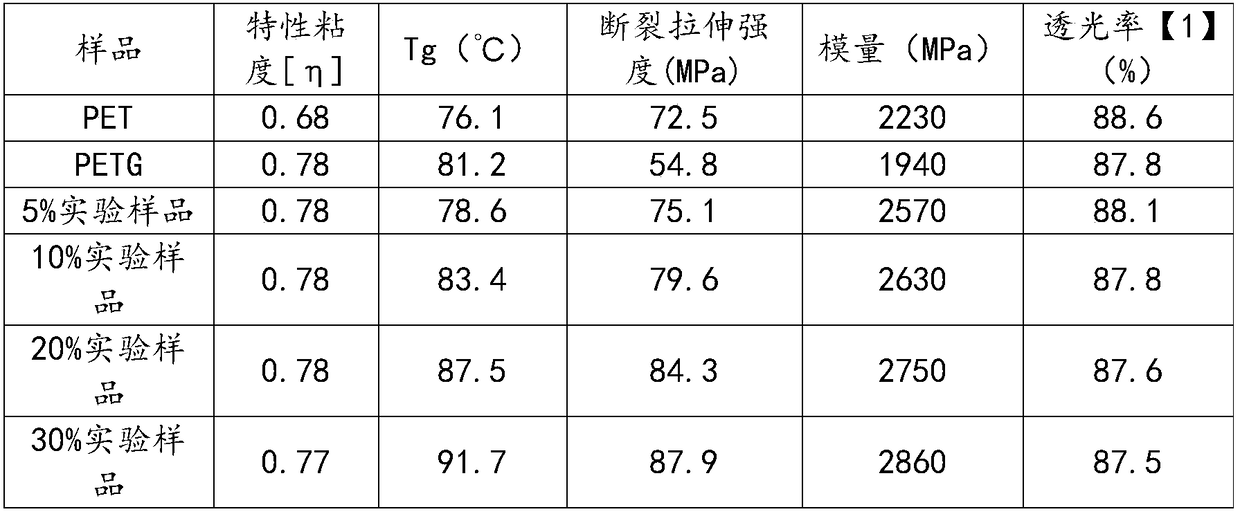

Examples

Embodiment 1

[0065] (1) Add terephthalic acid, catalyst, and stabilizer to 83.4ml of ethylene glycol, and stir evenly. Add cis-2,2,4,4-tetramethyl-1,3-cyclobutanediol to 30ml of ethylene glycol, heat to 75°C and stir evenly. Two kinds of slurries are formed and kept in a stirring state, wherein antimony glycol is used in an amount of 250 ppm; trimethyl phosphate is used in an amount of 8 ppm;

[0066] (2) Esterification: When the temperature in the kettle reaches 80°C, move the slurry into the reaction kettle, then turn on the stirring (50rpm), and replace the air in the kettle with nitrogen for 2 times, and then fill the kettle with nitrogen to make the inside of the kettle The pressure reaches 0.2MPa, and the temperature rises to 230°C. During the esterification process, the pressure in the kettle will continue to increase, and the pressure in the kettle will be adjusted and maintained by the regulating valve at the top of the fractionating tower. When the temperature at the top of the f...

Embodiment 2

[0070] (1) Add terephthalic acid, catalyst, and stabilizer to 73.8ml of ethylene glycol, and stir evenly. Add cis-2,2,4,4-tetramethyl-1,3-cyclobutanediol to 35ml of ethylene glycol, heat to 80°C, and stir evenly. Two kinds of slurries are formed and kept in a stirring state, the consumption of ethylene glycol antimony is 260 ppm; the consumption of trimethyl phosphate is 9 ppm;

[0071] (2) Esterification: When the temperature in the kettle reaches 80°C, move the slurry into the reaction kettle, then turn on the stirring (50rpm), and replace the air in the kettle with nitrogen for 2 times, and then fill the kettle with nitrogen to make the inside of the kettle The pressure reaches 0.3MPa, and the temperature rises to 250°C. During the esterification process, the pressure in the kettle will continue to increase, and the pressure in the kettle will be adjusted and maintained by the regulating valve at the top of the fractionating tower. When the temperature at the top of the fra...

Embodiment 3

[0075] (1) Add terephthalic acid, catalyst, and stabilizer to 70.2ml of ethylene glycol, and stir well. Add cis-2,2,4,4-tetramethyl-1,3-cyclobutanediol to 30ml ethylene glycol, heat to 78°C, stir evenly to form two kinds of slurry, keep stirring, ethylene glycol Antimony, the dosage is 270ppm; trimethyl phosphate, the dosage is 10ppm;

[0076] (2) Esterification: When the temperature in the kettle reaches 80°C, move the slurry into the reaction kettle, then turn on the stirring (50rpm), and replace the air in the kettle with nitrogen for 2 times, and then fill the kettle with nitrogen to make the inside of the kettle The pressure reaches 0.4MPa, and the temperature rises to 240°C. During the esterification process, the pressure in the kettle will continue to increase, and the pressure in the kettle will be adjusted and maintained by the regulating valve at the top of the fractionating tower. When the temperature at the top of the fractionating tower reaches 120°C, the esterifi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| tensile strength at break | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com