Composite membrane bioreactor with low energy consumption

A biological reaction device and composite membrane technology, applied in the direction of sustainable biological treatment, biological water/sewage treatment, water treatment parameter control, etc., can solve the problem of high energy consumption, achieve improved reaction effect, simple and convenient use, and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

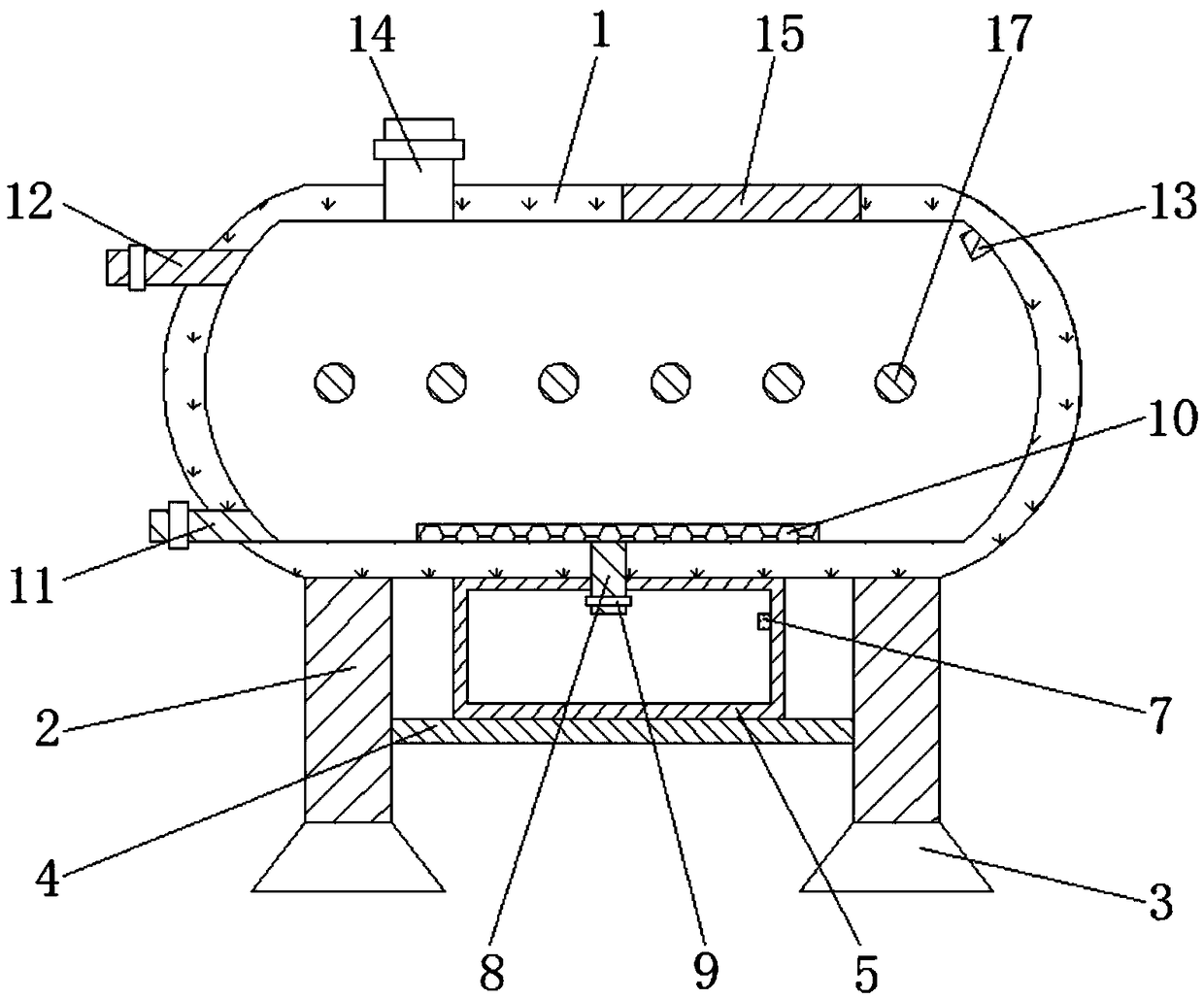

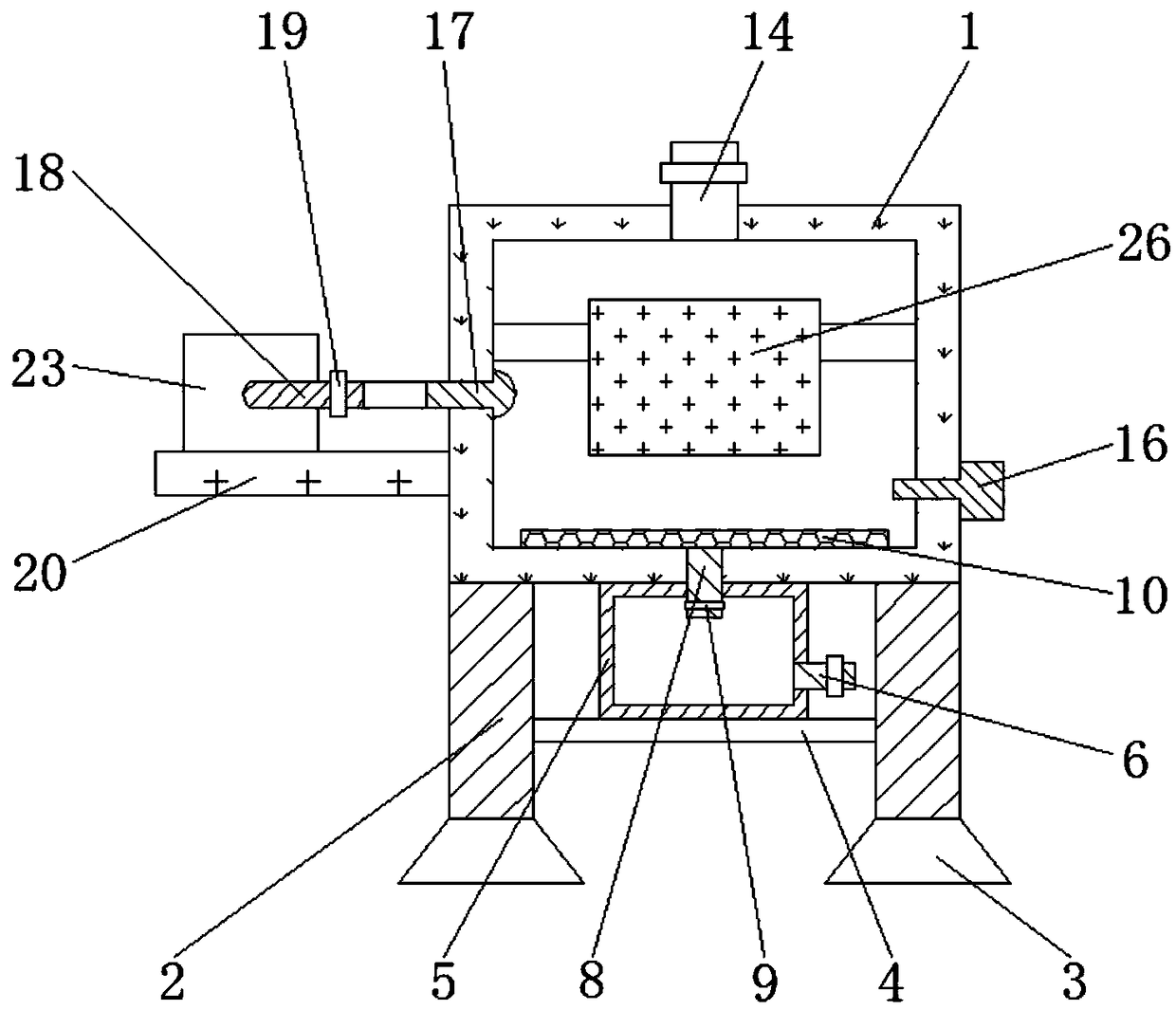

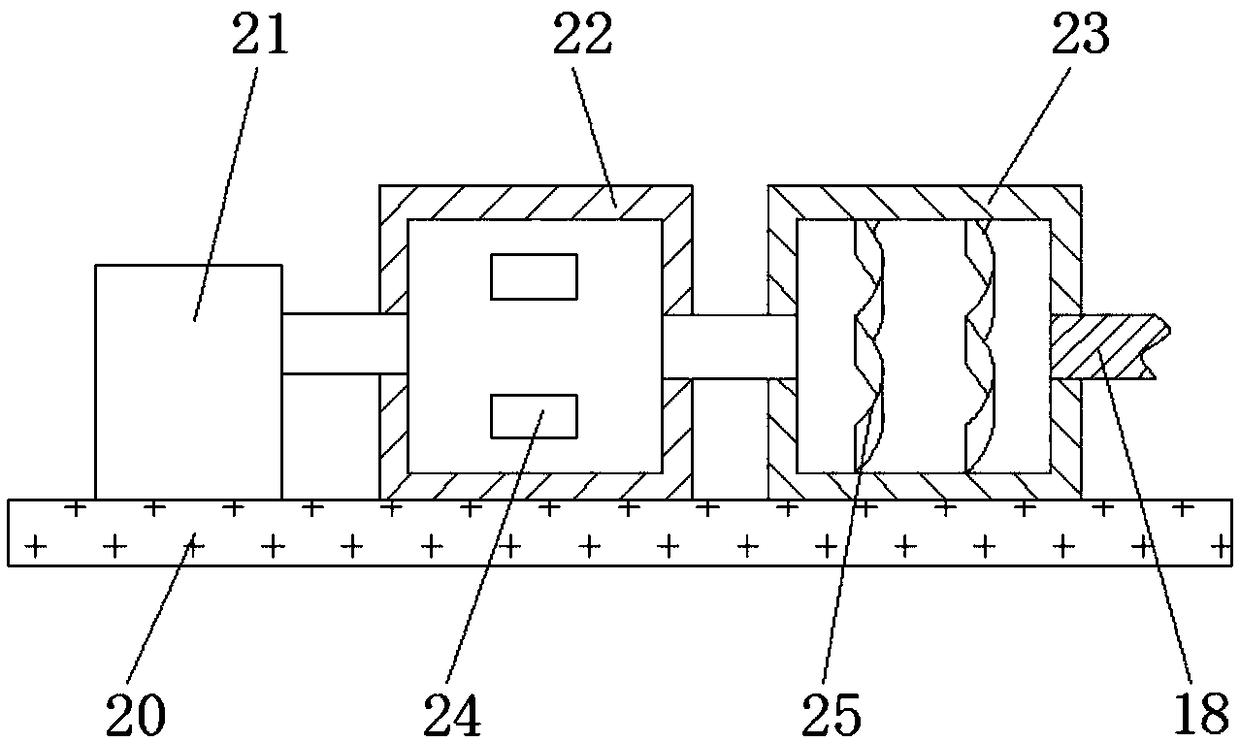

[0022] refer to Figure 1-3 , a composite membrane bioreactor with low energy consumption, comprising a reaction tank 1, the four corners of the outer wall of the bottom of the reaction tank 1 are equipped with vertically arranged support columns 2 through bolts, and the bottom outer walls of the support column 2 are installed with supports through bolts Seat 3, four support columns 2 are installed with the same horizontal support plate 4 through bolts, and the top outer wall of support plate 4 is installed with water tank 5 through bolts, and the outer wall of one end of water tank 5 is installed with water outlet pipe 6 through bolts, And the top of the inner wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com