Beverage filling space sterilizing and disinfecting device

A technology for sterilization and disinfection equipment and filling space, which is applied in packaging, bottling machines, bottle filling, etc. It can solve the problems of unqualified beverage products, aseptic cold filling space cannot maintain aseptic conditions, etc., and achieve good sterilization and disinfection Effect of treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with embodiment.

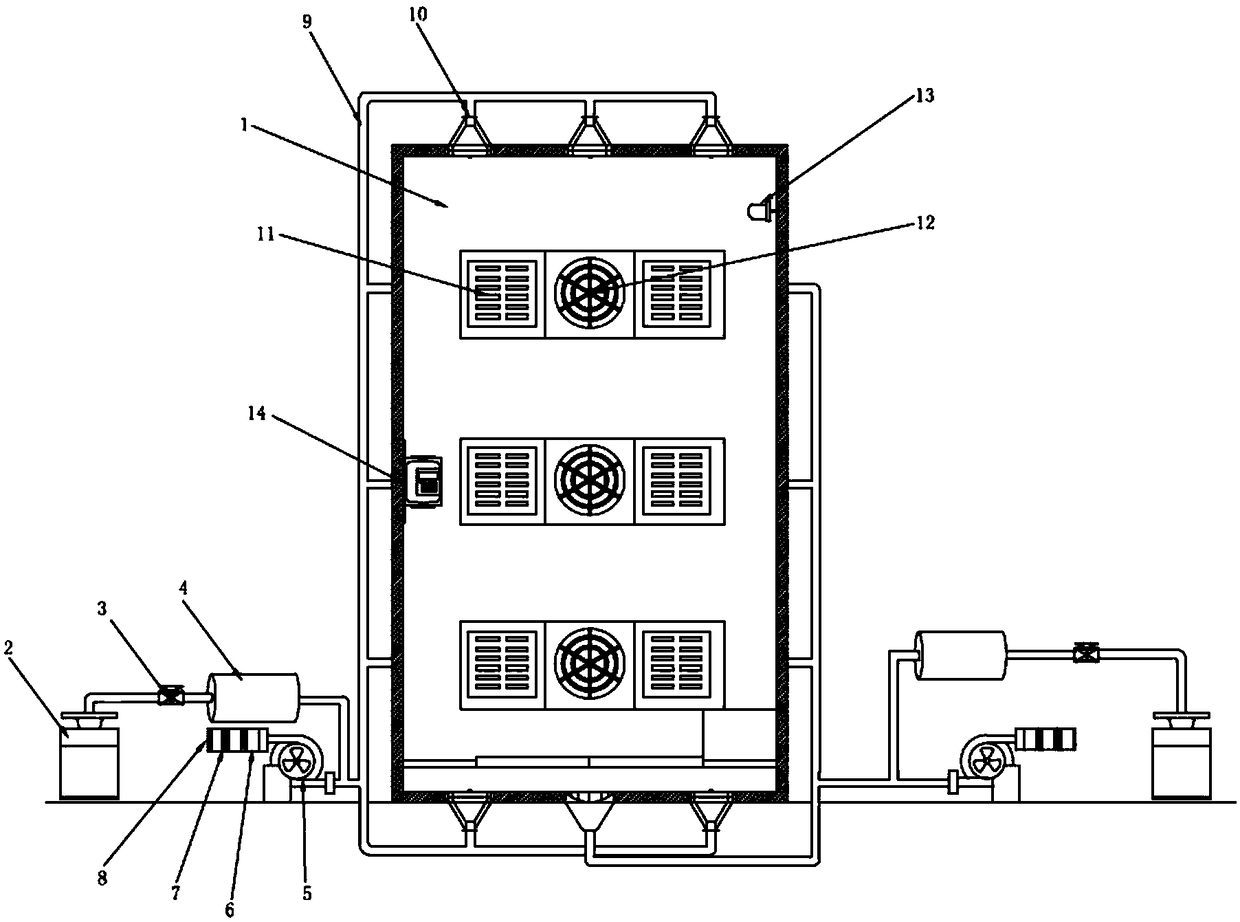

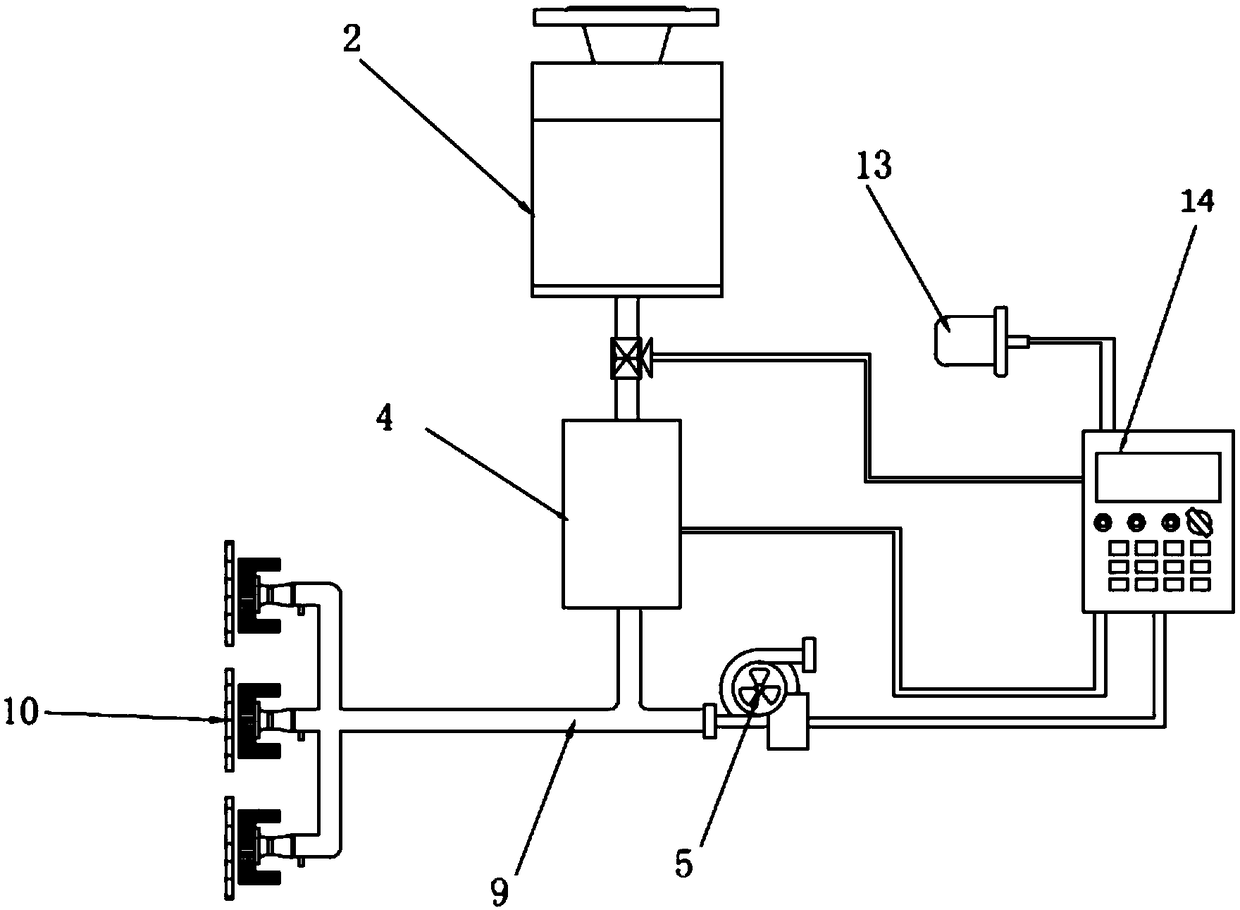

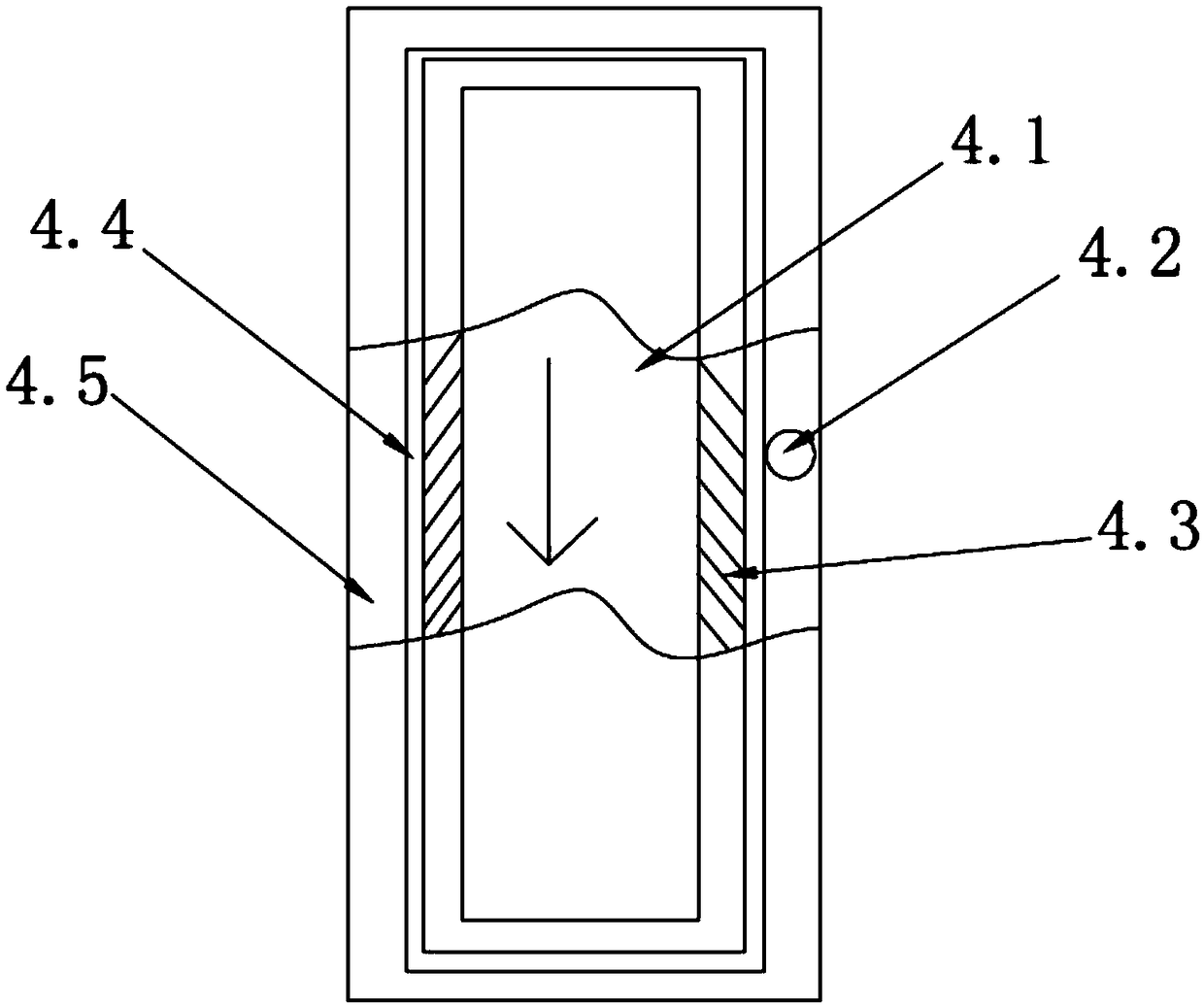

[0025] A sterilization and disinfection device for beverage filling space, such as Figure 1-3 As shown, the filling space 1 is included, and the filling space 1 is a closed production line or a closed production workshop for aseptic cold filling of beverages. It also includes a high-pressure sterilizing liquid tank 2, a sterilizing liquid switch 3, a vaporization device 4, an air pump 5, a transmission pipe 9, a nozzle 10, an exhaust fan 12 and a control panel 14. The output end of the high-pressure sterilizing liquid tank 2 is connected to the vaporization device 4 through the sterilizing liquid switch 3 . The high-pressure storage sterilizing liquid tank 2 is filled with hydrogen peroxide solution, sodium hypochlorite solution or chlorine dioxide solution for high-pressure extrusion. After the sterilizing liquid switch 3 is turned on, the sterilizing liquid in the high-pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com