Devices for transporting winding shafts in web winding machines

A technology of winder and fiber web, applied in the direction of winding mechanism, fiber processing, winding strip, etc., to achieve the effect of easy formation and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

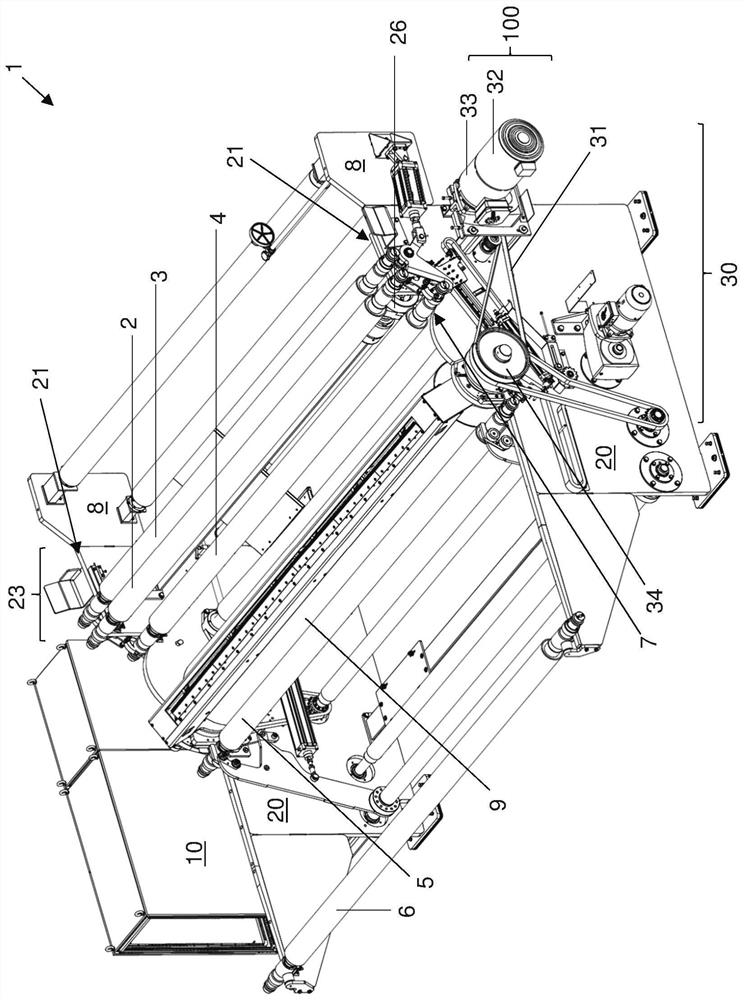

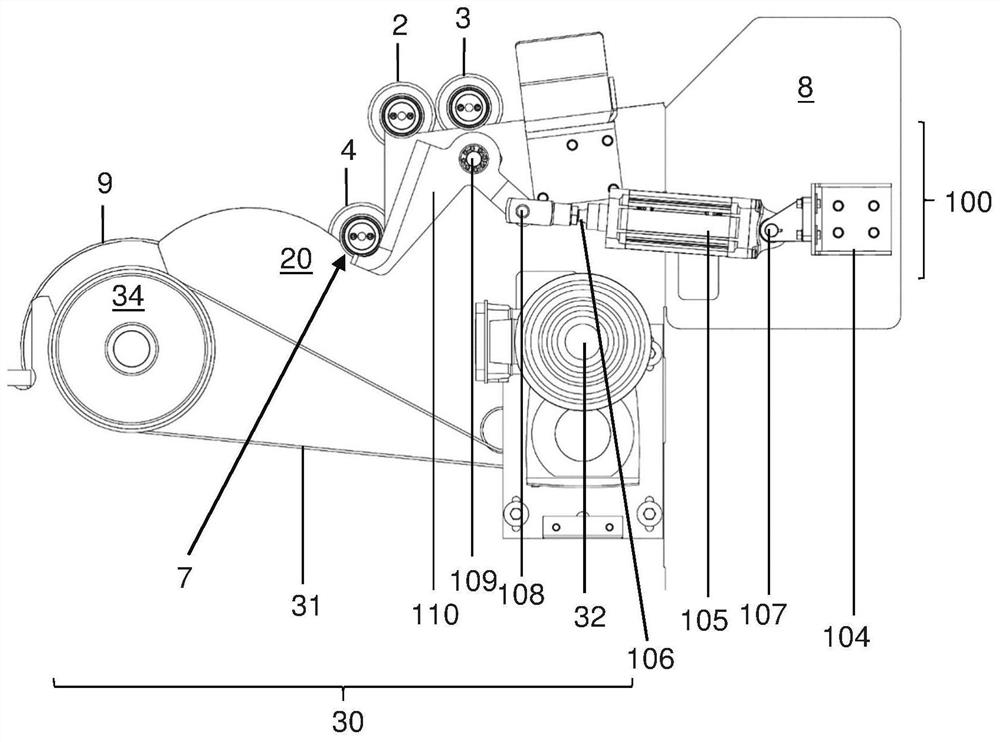

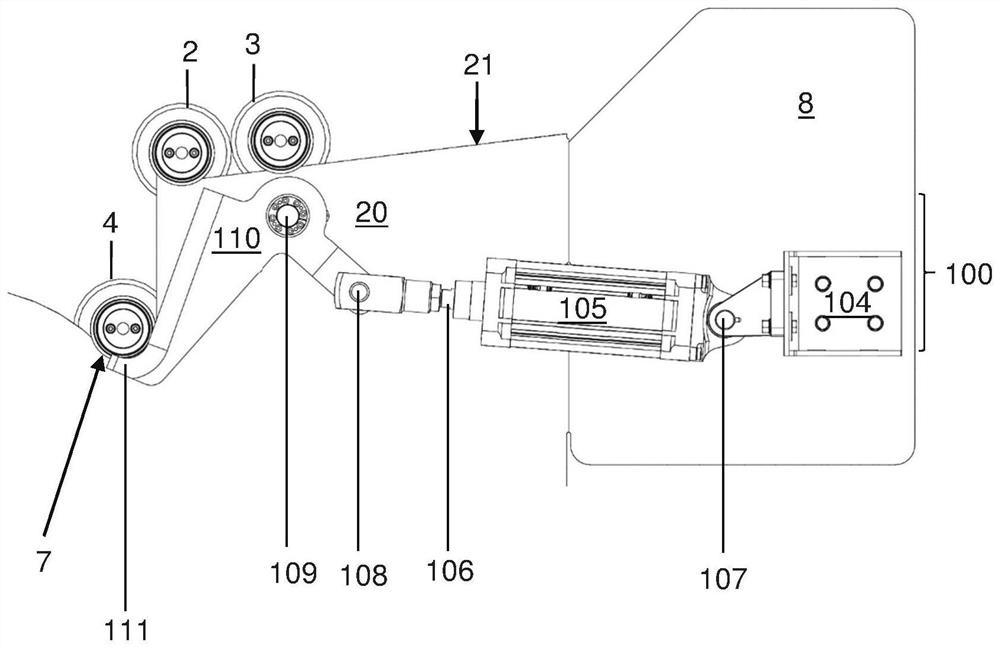

[0033] figure 1 A web winding machine 1 according to a first embodiment of the invention is shown.

[0034] The web winding machine 1 comprises two frame walls 20 which are adjusted to stand parallel to each other on the ground. Both housing walls 20 each have an attachment 8 at their here-right ends, but the attachments can also be formed in one piece with the respective housing wall 20 .

[0035] The frame walls 20 form the frame with reinforcement profiles, not shown, arranged between them and fastened thereto.

[0036] A control cabinet 10 is located on the rear side of the rear frame wall 20 , in which, for example, the controller of the web winding machine 1 is arranged.

[0037] Also shown is the drive section 30, which is adjusted to drive the contact roller 9 rotationally by means of a belt drive, whereby a winding shaft, not shown here, which rests against the contact roller can be wound by the fiber web, the fiber web from the contact Roll 9 is transferred to tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com