Paper box forming face paper feeding device and method

A conveying device and push device technology, applied in paper/cardboard containers, packaging, papermaking, etc., can solve the problems of complex feeding process, low production efficiency, unstable quality of finished products, etc., and achieve convenient use, high production efficiency and high quality , the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

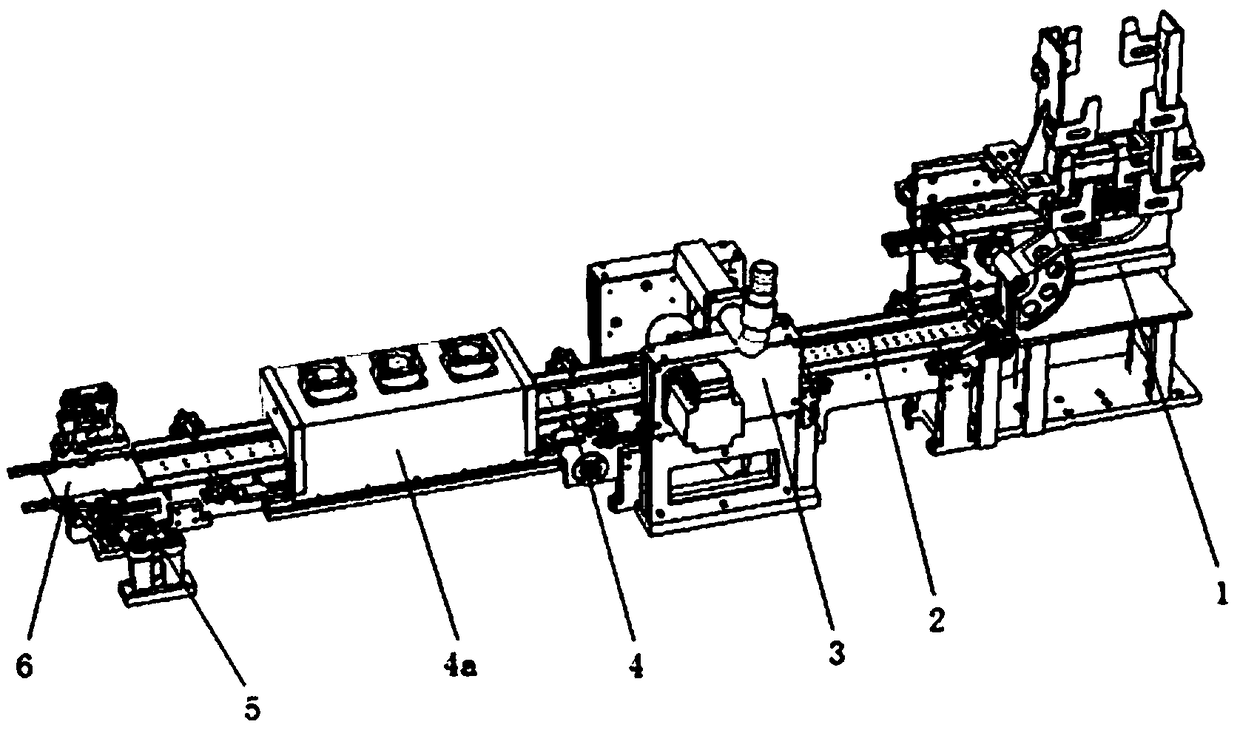

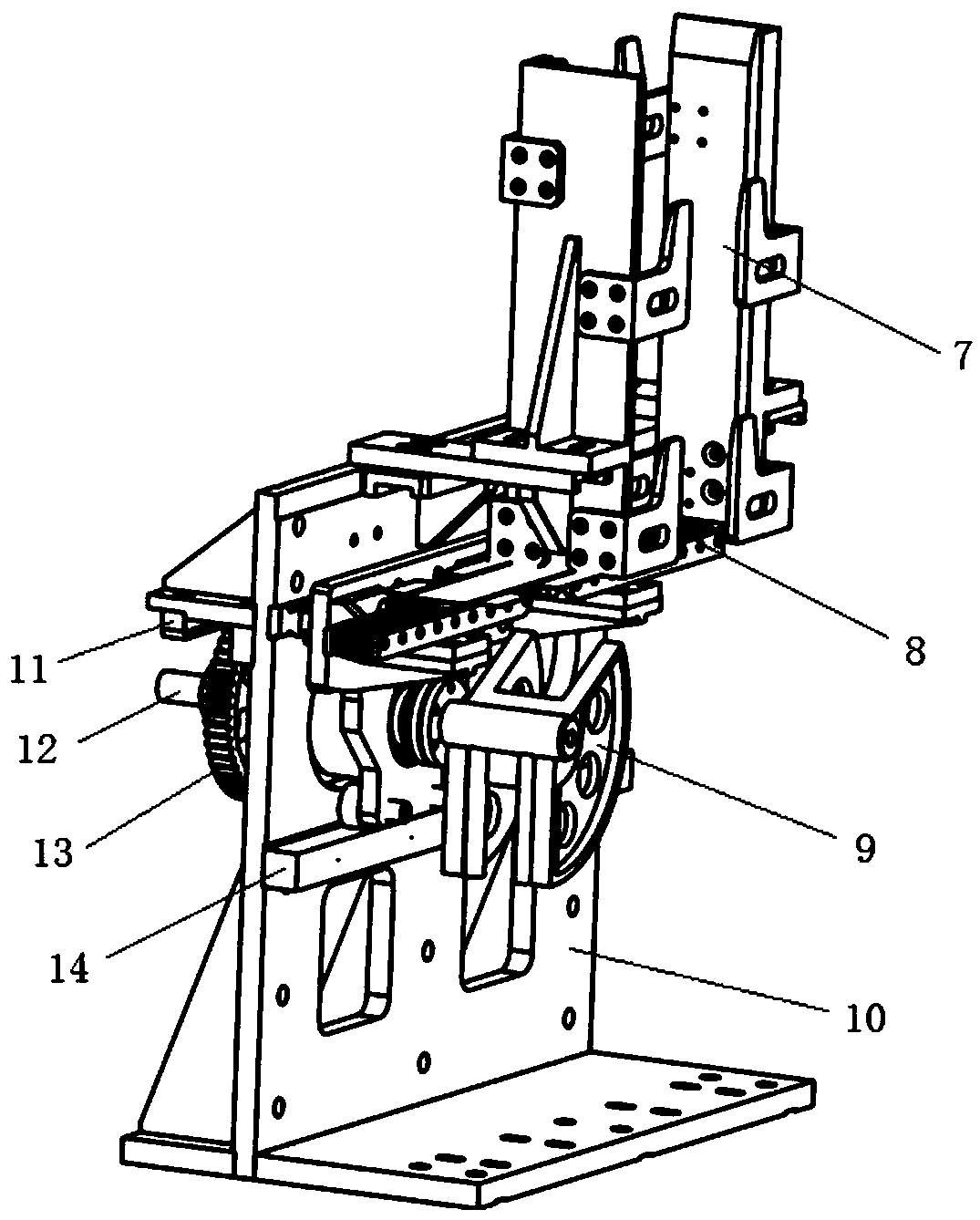

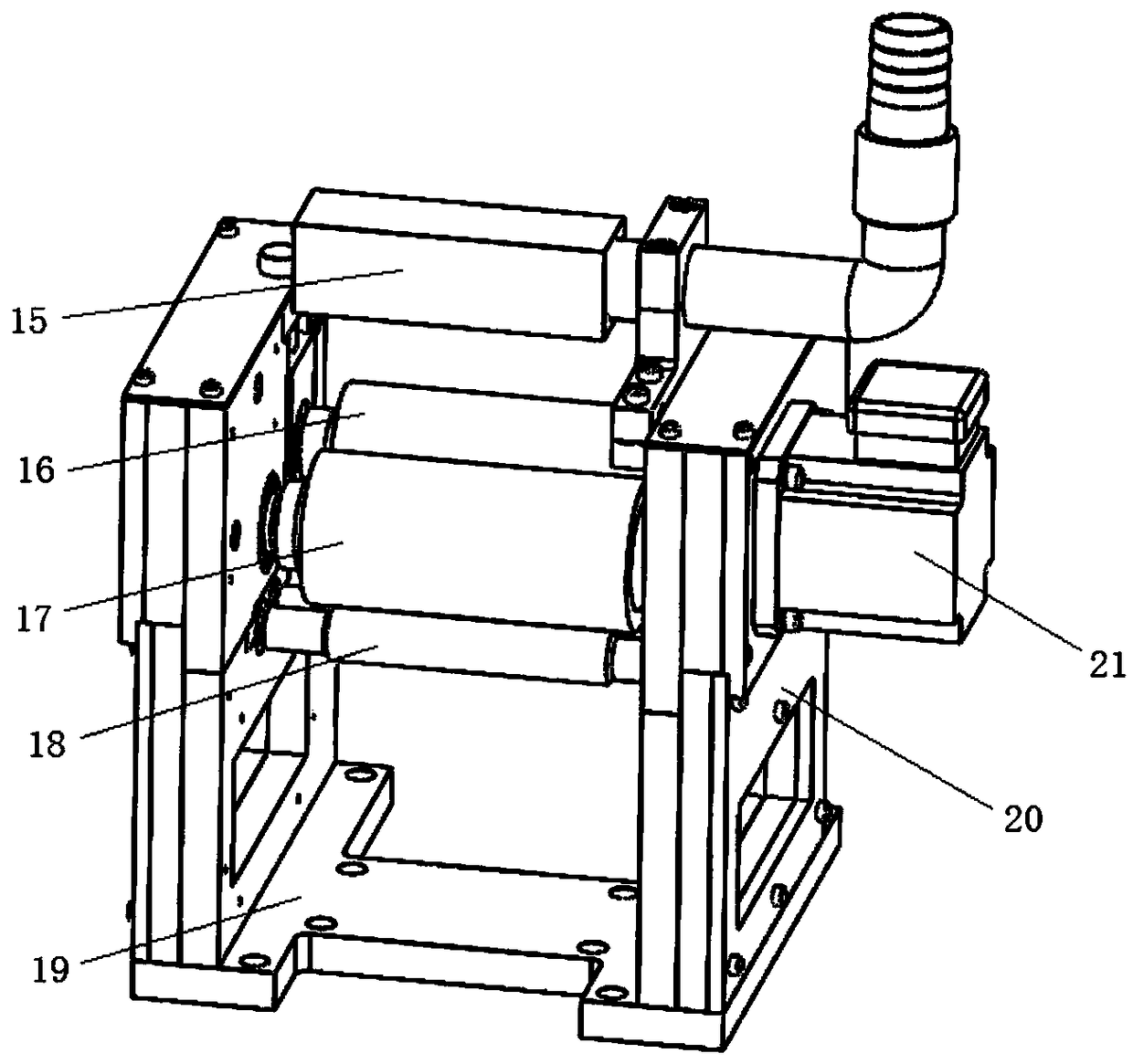

[0048] The main process of the present invention for tissue paper feeding is as follows:

[0049] Pack 60% of facial paper into the limit box 7——> The suction cup 9 vacuum sucks the single sheet from the bottom of the limit box 7——> The suction cup 9 rotates to place the paper on the first conveying device 2, and the suction cup 9 rotates back to the bottom of the limit box 7 to continue the adsorption and separation of the next piece of paper -> The facial paper 6 is sucked by the negative pressure on the first conveying device 2 and transferred to the gluing device 3——> Glue on face paper——> The glued facial paper is adsorbed by negative pressure on the second conveying device 4 and heated and dried through the heating channel 4a -> The dried facial paper 6 is sent to the pushing device 5——> The clamping push block 22 on the pushing device 5 clamps the limit facial paper 6——> The clamping and pushing block 22 pushes the facial paper 6 along the slide rail 23 to the next carton for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com