Anti-theft well lid automatic machining equipment

A technology of automatic processing and equipment, applied in metal processing equipment, grinding/polishing equipment, manufacturing tools, etc., can solve problems such as inaccurate positioning of workbench covers, affecting processing quality, and difficult automatic transportation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Such as figure 1 , figure 2 As shown, an anti-theft manhole cover automatic processing equipment includes a cutting unit 100, a supporting unit 200, a loading and unloading unit 300, a base 400, a cooling water pump 600, a cooling water tank 700, and an operating table 500. The cutting unit 100, the supporting unit 200, The loading and unloading unit 300 , the cooling water pump 600 , the cooling water tank 700 and the console 500 are all installed on the base 400 , and the lower end surface of the base 400 is provided with a shockproof adjustment pad 800 . The anti-shock adjustment horn 800 adjusts the level of the equipment and ensures the quality of processed products.

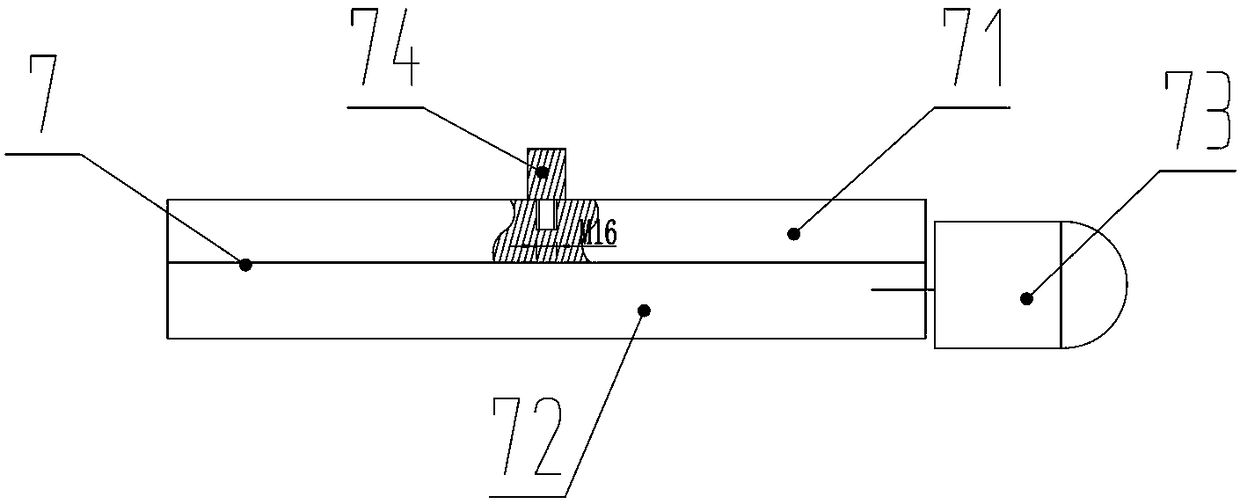

[0032] The cutting unit 100 includes a feeding mechanism 1 and a grinding wheel mechanism 2 installed on the feeding mechanism 1, the feeding mechanism 1 includes an X-axis feeding device 11 and a Y-axis feeding device 12, and the grinding wheel mechanism 2 includes The grinding wheel frame 21 and...

Embodiment 2

[0047] Such as Figure 7 , Figure 8 As shown, the difference between it and Embodiment 1 is that: the upper surface of the concave table 81 is gradually depressed from its periphery to the center to form a pot-shaped surface matching the workpiece. The shape of the pot-shaped surface is similar to the shape of the workpiece, and the workpiece falls on the pot-shaped surface and is moved by gravity to the position where the pot-shaped surface fits, which promotes the accuracy of positioning.

[0048] A through hole 87 is opened in the center of the concave table top 81 , and the upper end of the positioning electromagnet 82 enters the through hole 87 to attract the workpiece. The positioning electromagnet 82 directly applies a magnetic force to the workpiece to promote accurate positioning of the workpiece.

[0049] This equipment is a fully automatic processing equipment that adopts programming control, automatic feeding, automatic positioning, automatic pressing, coolant d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com