A base for brazing aluminum alloy cold plate

A technology of aluminum alloy and cold plate, applied in the direction of welding equipment, metal processing equipment, welding/welding/cutting items, etc., to achieve the effect of avoiding mutual interference and small friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings.

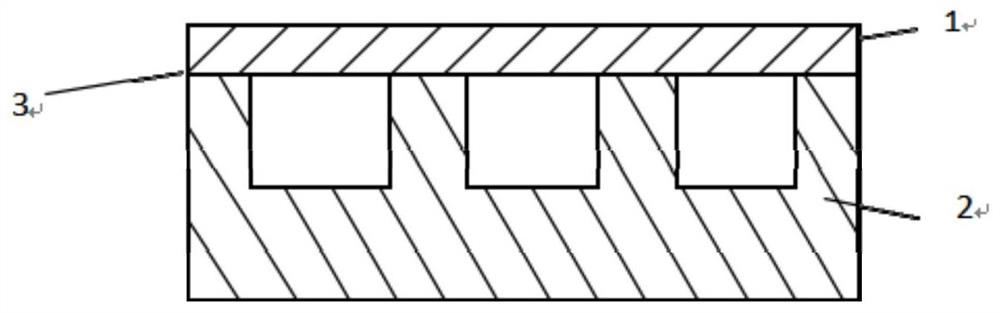

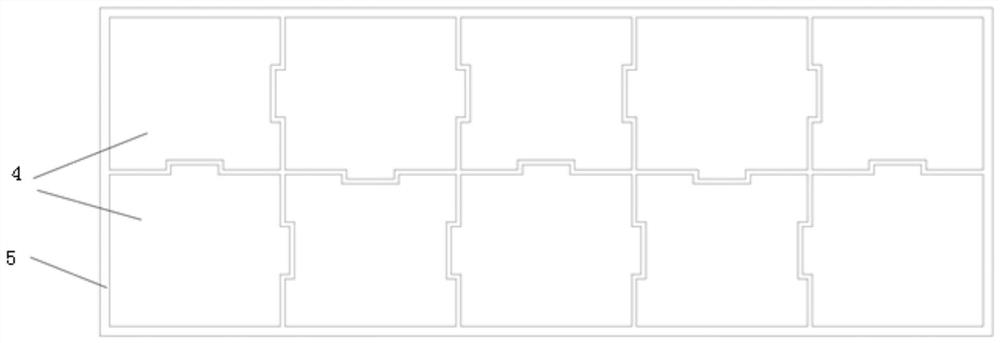

[0020] Such as figure 2 As shown, the grade of the aluminum alloy cold plate is 6063, which is composed of the lower bottom plate 2 with channel grooves and the upper cover plate 1 in the form of a flat plate, and the size of the aluminum alloy cold plate is 896×308×24mm. After the surface treatment of the aluminum alloy cold plate, brazing material is added to the welding surface 3, the upper cover plate 1 and the lower base plate 2 are positioned by positioning pins, placed on the base plate 4 and the support plate 5, and then placed in a stainless steel tooling frame and applied Reinforced tightness, using vacuum brazing welding. The method steps are as follows:

[0021] (1) Make graphite base plate 4 and support plate 5, and make 10 base plates 4, each with a size of 180×160×10mm (calculate the size of the junction according to the midline of the concave and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com