Pipe fitting drilling device

A technology of drilling device and pipe fittings, applied in the direction of boring/drilling, drilling/drilling equipment, and components of boring machine/drilling machine, etc., can solve the problem of inability to realize multiple sets of drilling operations, single setting mode, and reduce processing efficiency and other problems, to achieve the effect of improving punching efficiency and punching effect, high degree of automation, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

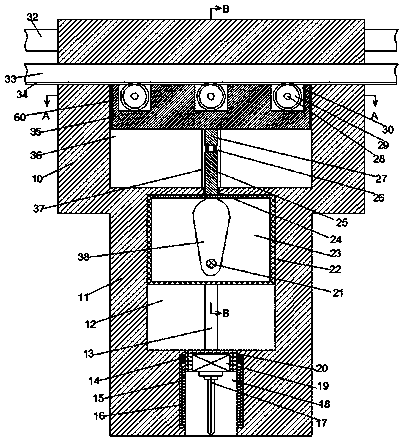

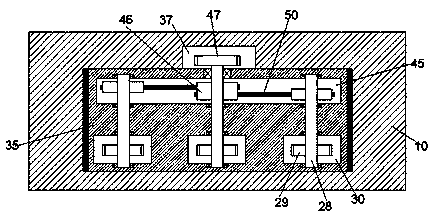

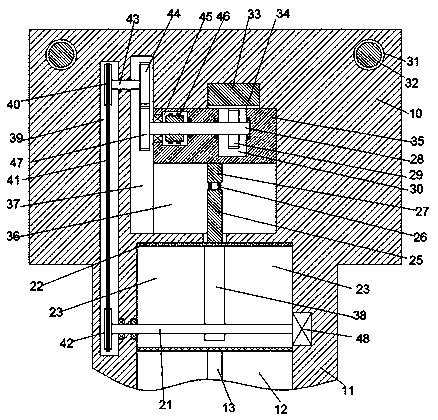

[0018] Such as Figure 1-3 As shown, a pipe fitting drilling device of the present invention includes a moving frame 10 and an installation frame 11 integrally arranged at the bottom of the moving frame 10, the moving frame 10 is provided with a first slide groove 36, and the first The inner top wall of the sliding groove 36 is provided with a left and right through the first sliding hole of the mobile frame 10, and the left and right ends are slidably installed in the first sliding hole. A rack 34 is extended, and a first sliding block 35 is slidably installed in the first sliding groove 36. A rolling device is provided on the first sliding block 35, and the rolling device includes a rolling sleeve 60. The first The sliding block 35 is provided with multiple sets of first rotating cavities 30, and the second rotating cavity 45 is extended left and right in the first sliding block 35 on the rear side of the first rotating cavity 30, and the first rotating cavity 30 and A plur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com