Riveting machine

A riveting machine and riveting technology, applied in the field of relays, can solve problems such as not being able to meet the production and quality requirements of parts, unstable product quality, and high labor intensity, and achieve simple structure, smooth riveting process, and improved safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

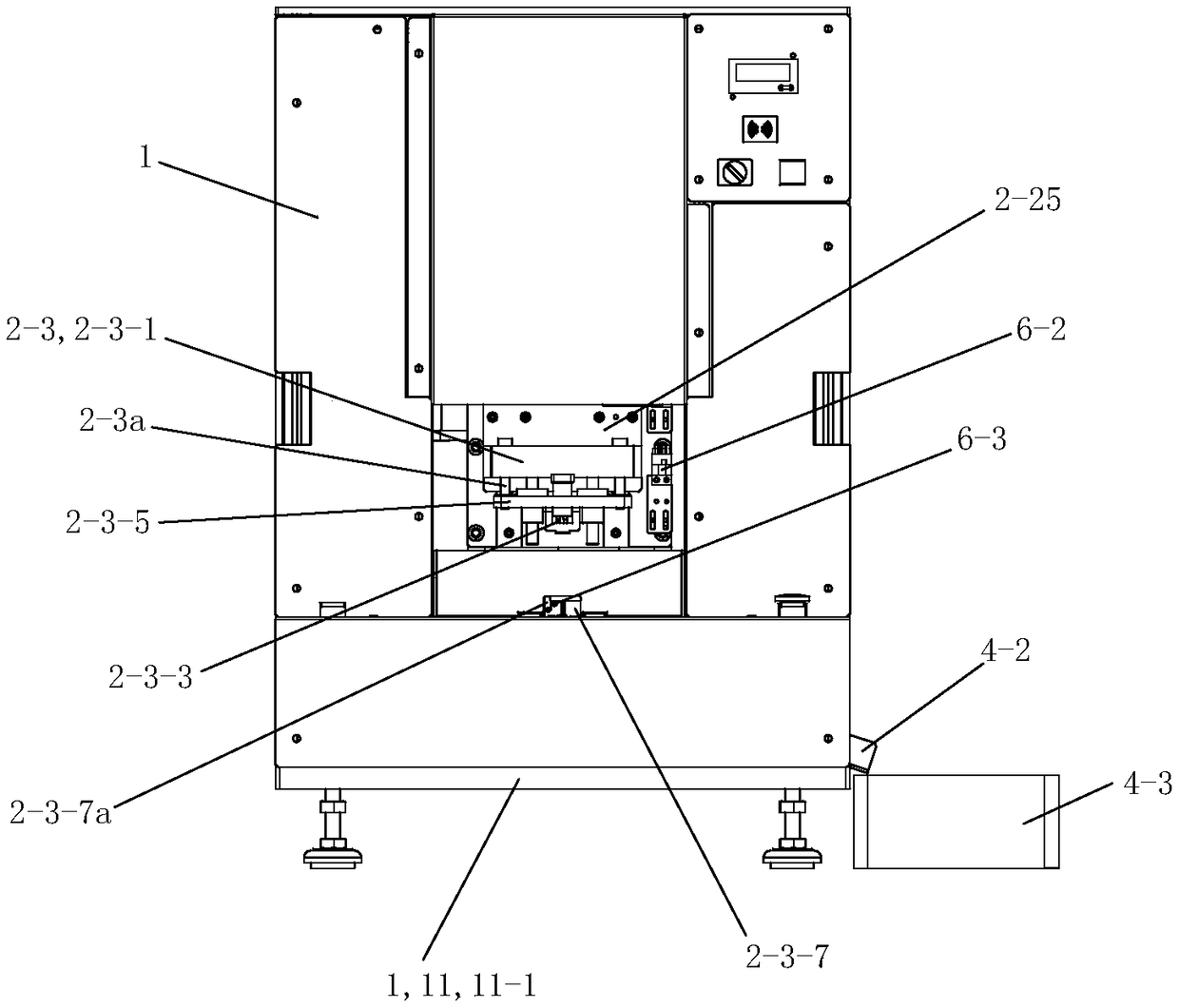

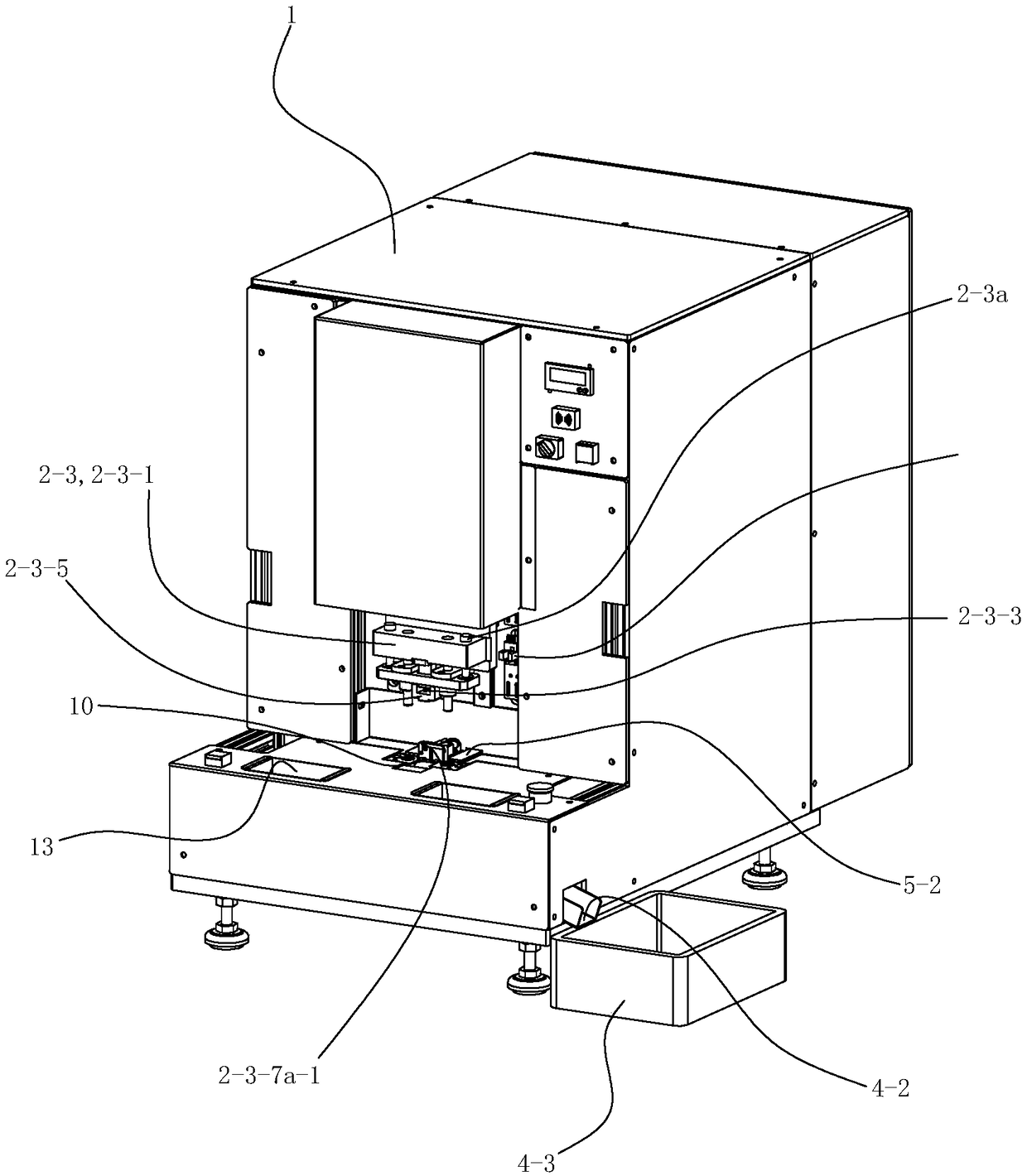

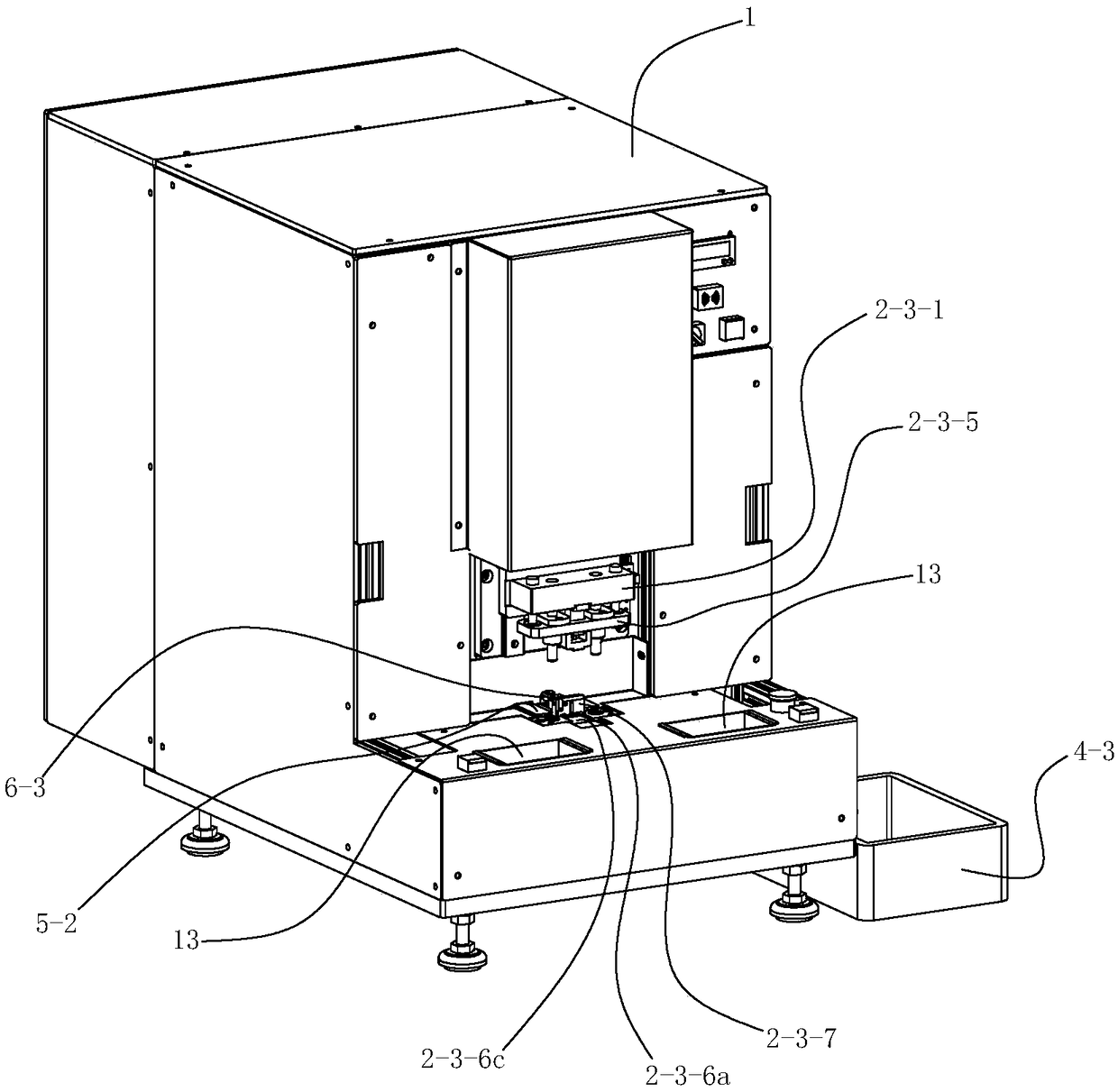

[0073] See Figure 1 to Figure 15 , The riveting machine of the present invention includes a frame 1, a riveting device 2, a blocking device 3, a discharging device 4 and a protection device 5.

[0074] See Figure 1 to Figure 15 , The frame 1 includes a main frame body 11 and an inner frame body 12 . The lower part of the main frame body 11 is provided with an installation base plate 11-1. Corresponding sealing plates are provided around and on the top of the main frame body 11 . The lower part of the inner frame body 12 is provided with a second installation bottom plate 12-1. A support plate 12-2 is respectively provided on the left and right sides of the upper front portion of the second installation base plate 12-1. The inner frame body 12 is fixedly arranged on the upper side of the installation bottom plate 11 - 1 of the main frame body 11 by its second installation bottom plate 12 - 1 , and is located in the main frame body 11 . A raw material box 13 is arranged o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com