Single-driving hydraulic roller pressing sand machine

A single-drive, hydraulic technology, applied in solid separation, sieves, grids, etc., can solve the problems of uneven distribution of sand and gravel, affecting the particle size of sand and gravel, and avoid uneven distribution of sand and gravel. The effect of blocking and increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

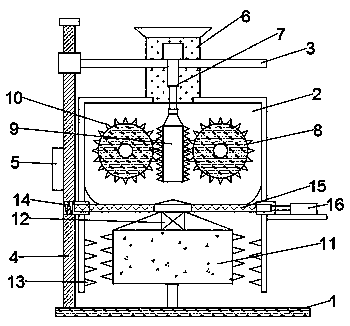

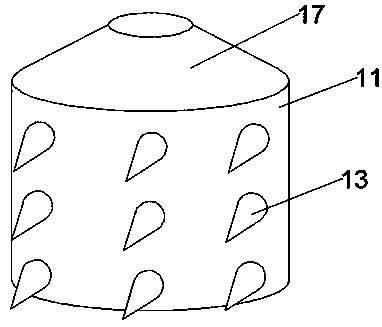

[0021] see Figure 1~4 , in an embodiment of the present invention, a single-drive hydraulic roller sand press machine includes a conveyor belt 1, a crushing box 2, a hydraulic roller 8 and crushing sawtooth 10, a crushing box 2 is arranged above the conveyor belt 1, and the left side of the crushing box 2 Fix the welding support column 4, the left side wall of the support column 4 is equipped with a PLC controller 5, the vertical bolt on the upper end of the support column 4 is connected to the support cross bar 3, the support cross bar 3 is arranged above the crushing box 2, and the The middle position of the upper surface of the crushing box 2 is provided with a feeding pipe 6, the feeding pipe 6 communicates with the crushing box 2, and two hydraulic rollers 8 are symmetrically installed on the inner top of the crushing box 2, and the hydraulic rollers 8 are connected to the crushing box 2. The side walls of the crushing box 2 are rotatably connected, and the outer surface...

Embodiment 2

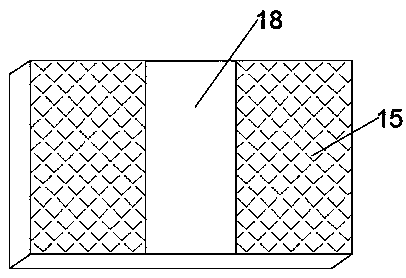

[0029] see figure 1 , 4 , in the embodiment of the present invention, the connection mode between the screen 15 and the side wall of the crushing box 2 is a sliding connection, and a buffer cavity 14 is set at the left end of the buffer chamber 14 in contact with the side wall of the crushing box 2, and the buffer chamber 14 The cavity 14 is fixedly welded on the side wall of the crushing box 2, and the inside of the buffer cavity 14 is provided with buffer springs 19 and connectors 20 from left to right, the right end of the connector 20 is welded to the screen 15, and the buffer Both ends of the spring 19 are respectively welded to the inner wall of the buffer cavity 14 and the left end of the connector 20;

[0030] The right side of the screen 15 is welded with a second hydraulic cylinder 16, and the second hydraulic cylinder 16 is fixedly installed in the middle of the right side wall of the crushing box 2. The second hydraulic cylinder 16 is electrically connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com