Polyurethane coating emulsifying device

A technology of polyurethane coating and emulsification device, applied in transportation and packaging, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of uneven stirring and increase the contact area, so as to increase the contact area and improve the stirring efficiency. , the effect of improving the emulsification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

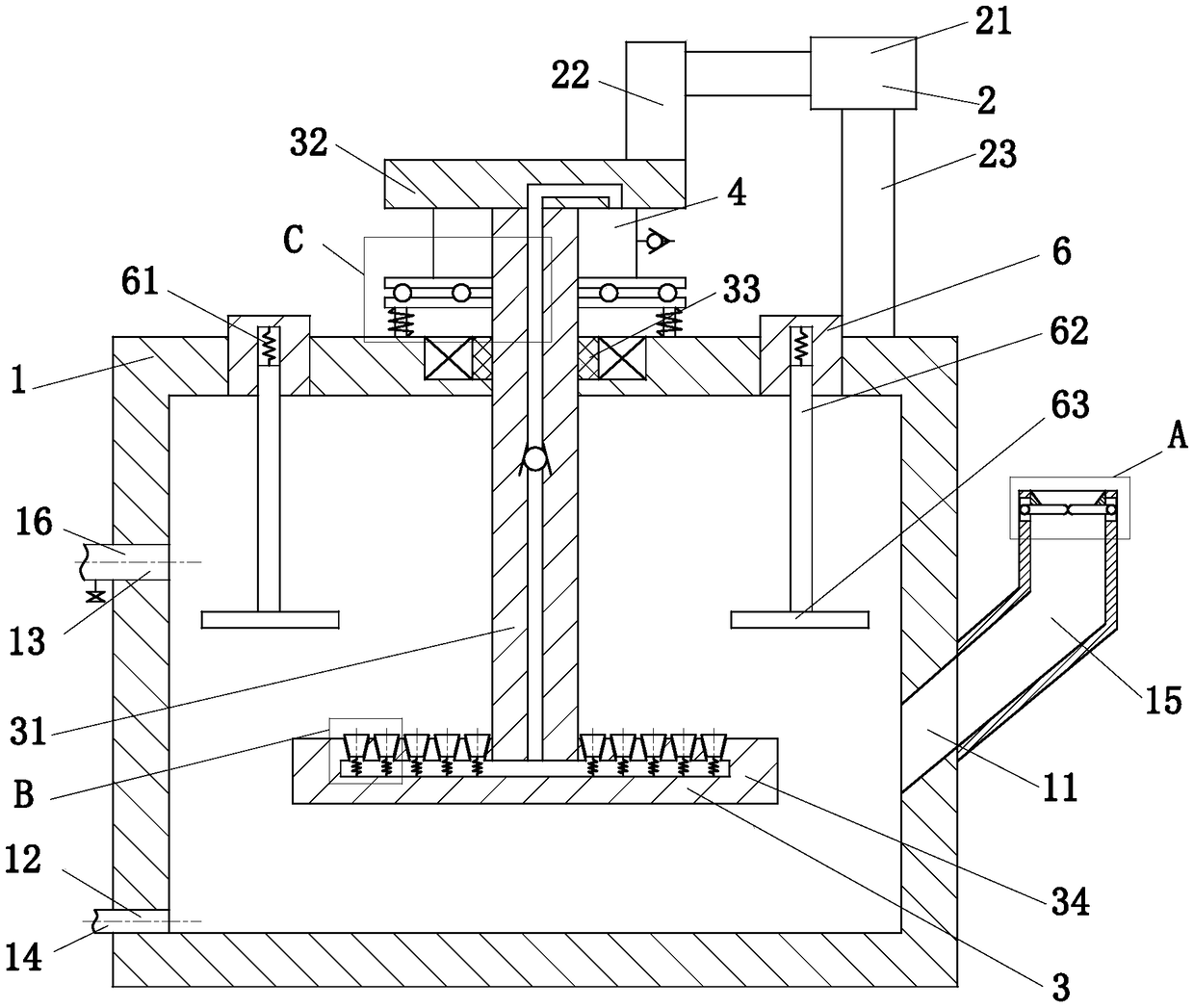

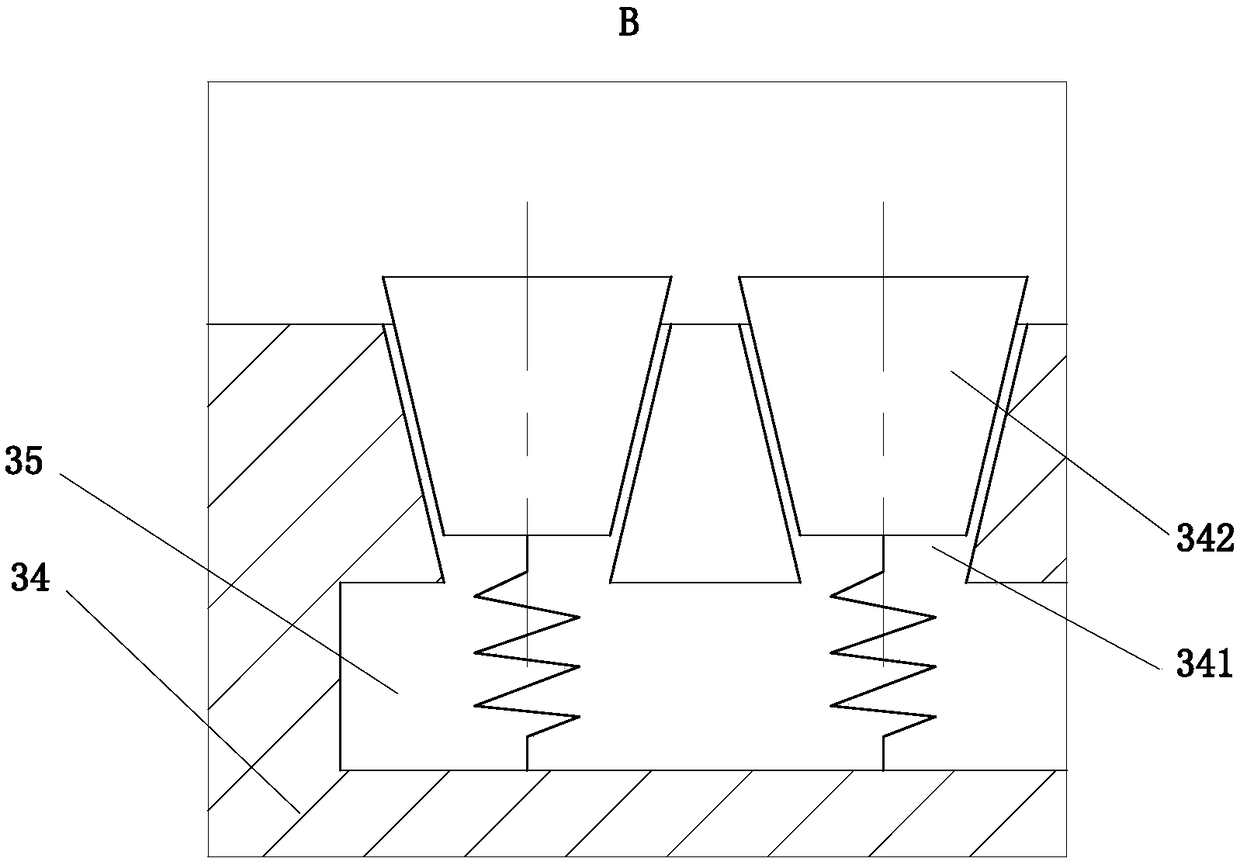

[0032] As an embodiment of the present invention, the stirring plate 34 is provided with a hollow chamber 35, and the top of the stirring plate 34 is provided with a No. 1 hole 341; the No. 1 hole 341 communicates with the hollow chamber 35; the telescopic unit 4 Including air bag 41, No. 1 channel 42, No. 2 plate 43, ball 44, No. 3 plate 45 and telescopic rod 46; one end of the air bag 41 is fixedly connected to the rotating disk 32, and the other end of the air bag 41 is fixedly connected to the No. 2 plate 43; the No. 2 plate 44 rolls on the No. 3 plate 45 through the ball 44; the No. 3 plate 45 is fixedly connected to the top of the emulsification tank 1 through the telescopic rod 46; the No. 1 channel 42 is used to communicate with the air bag 41 And hollow chamber 35, air bag 41 outside is provided with one-way valve, and its one-way valve is used for one-way suction, is connected with one-way valve on No. 1 channel 42, and its one-way valve is used for air bag 41 one-way...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com