Processing method of preserved meat product with fermentation flavor

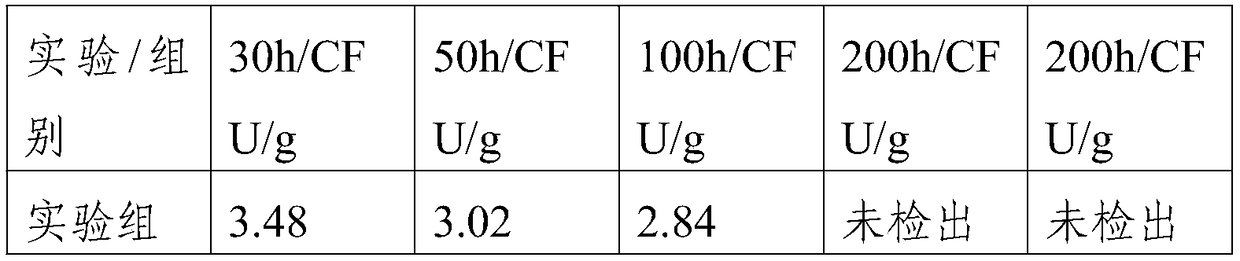

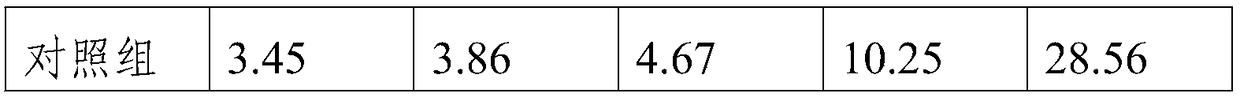

A technology of fermented flavor and processing method, applied in the direction of food ingredients, functions of food ingredients, bacteria used in food preparation, etc., can solve the problems of prone to diarrhea, no inhibitory effect, less cured bacon, etc., to improve the taste and taste As well as the nutritional value and the effect of inhibiting the growth of Escherichia coli

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method for processing cured bacon products with fermented flavor, comprising the following steps:

[0031] S1. Wash the pork and beef and drain properly to obtain the meat. Apply a layer of salt on the surface of the pork and beef, hammer the salt layer with a wooden stick until the salt layer is fully mixed with the meat, and beat the meat until rotten. ;

[0032] S2. Inoculate Lactobacillus, Pediococcus pentosaceae, Lactobacillus sake, and Staphylococcus xylose into the culture medium to obtain fermentation bacteria, and mix the fermentation bacteria into the sauce to obtain bacterial sauce;

[0033] S3. Fully mix the fungus sauce in step S2 with the battered meat in step S1, enema sausages to obtain sausages, place the sausages in a fermentation room for fermentation for 40 hours, control the temperature of the fermentation room at 35°C, and air-dry for 25 days. Place it under dead branches and smoke until the meat is cooked, then sterilize and pack it.

[0034] ...

Embodiment 3

[0038] A method for processing cured bacon products with fermented flavor, comprising the following steps:

[0039] S1. Wash the pork and beef and drain properly to obtain the meat. Apply a layer of salt on the surface of the pork and beef, hammer the salt layer with a wooden stick until the salt layer is fully mixed with the meat, and beat the meat until rotten. ;

[0040] S2. Inoculate Lactobacillus, Pediococcus pentosaceae, Lactobacillus sake, and Staphylococcus xylose into the culture medium to obtain fermentation bacteria, and mix the fermentation bacteria into the sauce to obtain bacterial sauce; S3. In step S2 Mix the fungus sauce with the meat beaten until rotten in step S1, enema the sausages to obtain sausages, place the sausages in the fermentation room for 36 hours, control the temperature of the fermentation room at 35.5°C, air-dry for 28 days, then place them under dead branches for smoking It is obtained after the meat is cooked, sterilized and packaged.

[00...

Embodiment 4

[0045] A method for processing cured bacon products with fermented flavor, comprising the following steps:

[0046] S1. Wash the pork and beef and drain properly to obtain the meat. Apply a layer of salt on the surface of the pork and beef, hammer the salt layer with a wooden stick until the salt layer is fully mixed with the meat, and beat the meat until rotten. ;

[0047] S2. Inoculate Lactobacillus, Pediococcus pentosaceae, Lactobacillus sake, and Staphylococcus xylose into the culture medium to obtain fermentation bacteria, and mix the fermentation bacteria into the sauce to obtain bacterial sauce; S3. In step S2 Mix the bacteria sauce with the beaten meat in step S1, enema the sausages to obtain sausages, place the sausages in the fermentation room for 38 hours, control the temperature of the fermentation room at 35.5°C, air-dry for 28 days, then place them under dead branches for smoking It is obtained after the meat is cooked, sterilized and packaged.

[0048] Wherein...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com