Process for improving white tea quality

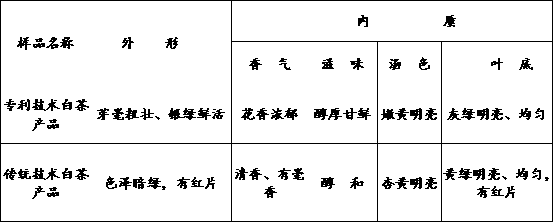

A technology of quality and craftsmanship, applied in the technical field of improving the quality of white tea, can solve the problems of easy browning of white tea appearance, long processing time, low efficiency, etc., and achieve the effect of shortening the processing time of white tea, improving quality and strong taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A kind of technique of improving white tea quality of the present invention comprises the following steps:

[0031] 1) Fresh leaf raw materials: Xilian No. 1 fresh leaves with 1 bud and 1 leaf or 1 bud and 2 leaves;

[0032] 2) Spread green: place the fresh leaves on the ventilated withering trough (the withering trough is 10m long and 2m wide). 3h, stop for 1h) to wither, turn the leaves 1-2 times in the middle, and spread them for 14h; When the gas is greatly reduced and the fragrance is emitted, it reaches the moderate mark;

[0033] 3) Green sun drying: at around 8:00 the next morning, spread the fresh leaves evenly on the bamboo grate or cotton cloth with a thickness of 1.5-2.0 cm, and place them in sunlight with a certain intensity of light to wither in the sun. During the process, the fresh leaves are properly turned, and the drying time is about 1 hour;

[0034] 4) Cooling: Place the fresh leaves on a ventilated withering trough (the length of the withering t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com