Fish body segment cutting and washing device based on freshwater fish processing

A cleaning device and technology for freshwater fish, applied in fish processing, fish cleaning/descaling, and cutting fish into parts, etc., can solve the problems of difficult guarantee of processing quality and low efficiency of manual operation, so as to improve the level of automation and facilitate cutting section, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

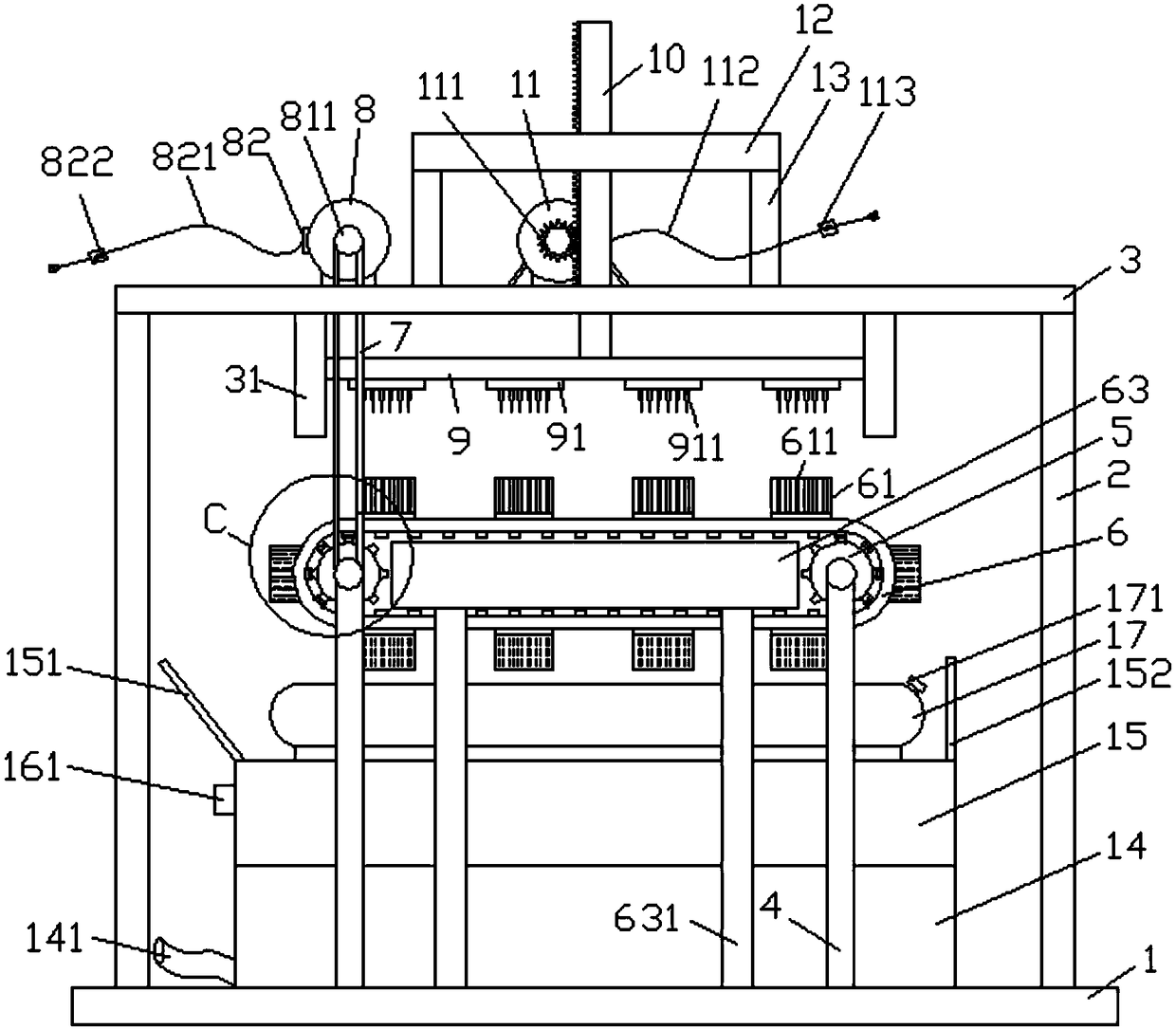

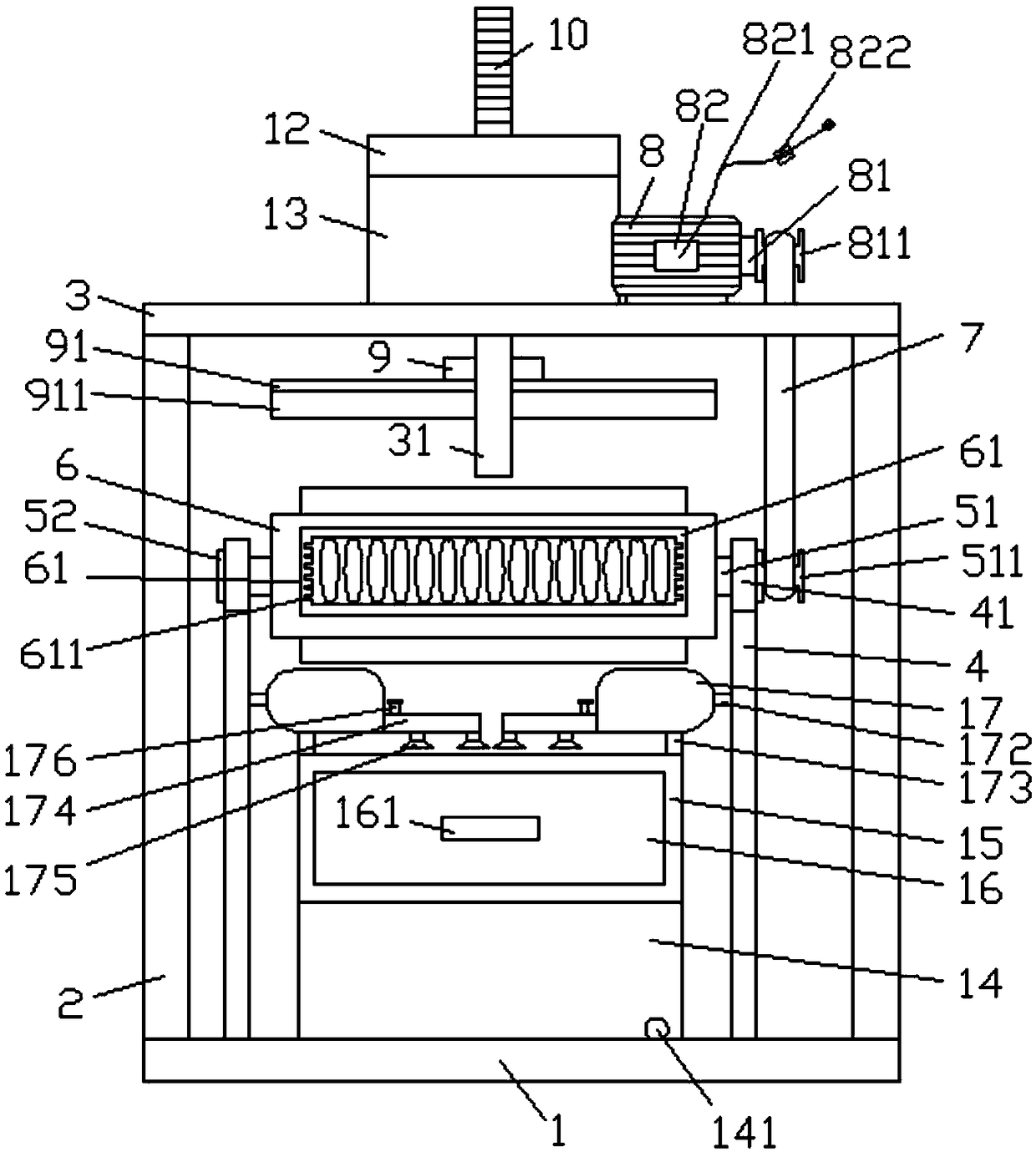

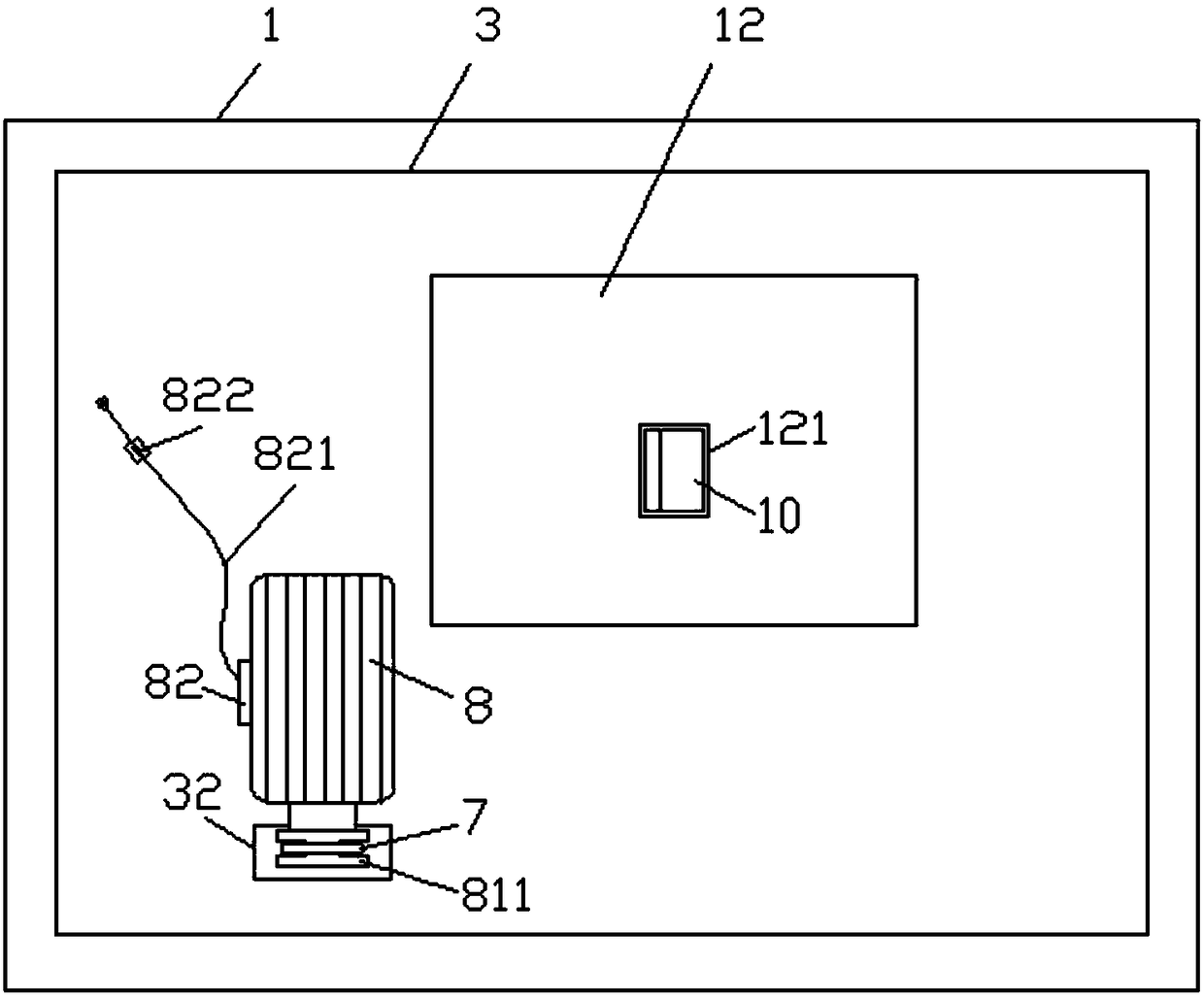

[0059] Such as Figure 1 to Figure 8 As shown, this kind of fish body section cleaning device based on freshwater fish processing has a structure including a cuboid bottom plate, and the four corners of the upper surface of the bottom plate are respectively welded with vertical first poles 2, and the first The upper end of the vertical rod 2 is welded to the four corners of the lower surface of the first horizontal plate 3 respectively, and the upper surface of the bottom plate inside the first vertical rod 2 is also welded with two pairs of second vertical rods 4 corresponding to the front and rear. The second vertical rod 4 Horizontal bearings 41 are respectively welded to the upper end, and first rotating shafts 51 are erected between the bearings 41 on the front and rear sides respectively. The middle parts of the first rotating shafts 51 are respectively fixedly sleeved with winding rollers 51, and the outer portions of the winding rollers 51 The surface is respectively p...

Embodiment 2

[0071] Such as Figure 3 to Figure 11 As shown, this kind of fish body section cleaning device based on freshwater fish processing has a structure including a cuboid bottom plate, and the four corners of the upper surface of the bottom plate are respectively welded with vertical first poles 2, and the first The upper end of the vertical rod 2 is welded to the four corners of the lower surface of the first horizontal plate 3 respectively, and the upper surface of the bottom plate inside the first vertical rod 2 is also welded with two pairs of second vertical rods 4 corresponding to the front and rear. The second vertical rod 4 Horizontal bearings 41 are respectively welded to the upper end, and first rotating shafts 51 are erected between the bearings 41 on the front and rear sides respectively. The middle parts of the first rotating shafts 51 are respectively fixedly sleeved with winding rollers 51, and the outer portions of the winding rollers 51 The surface is respectively ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com