Anti-vibration hammer with convenient replacement structure and machining process of anti-vibration hammer

A processing technology and anti-vibration hammer technology, which is applied in the field of anti-vibration hammer and its processing technology, can solve the problems of easy loosening of springs and sliders, low connectivity, and increased costs, so as to avoid side deviation, avoid sliding, and save costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

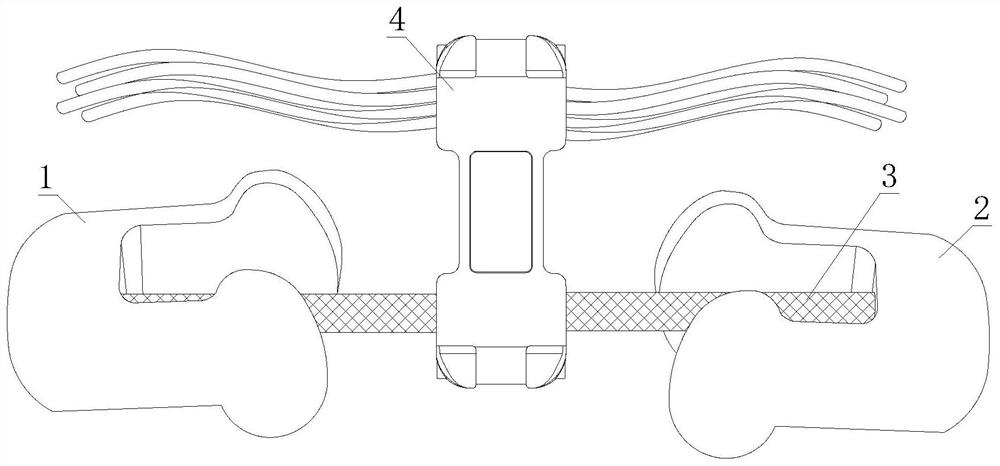

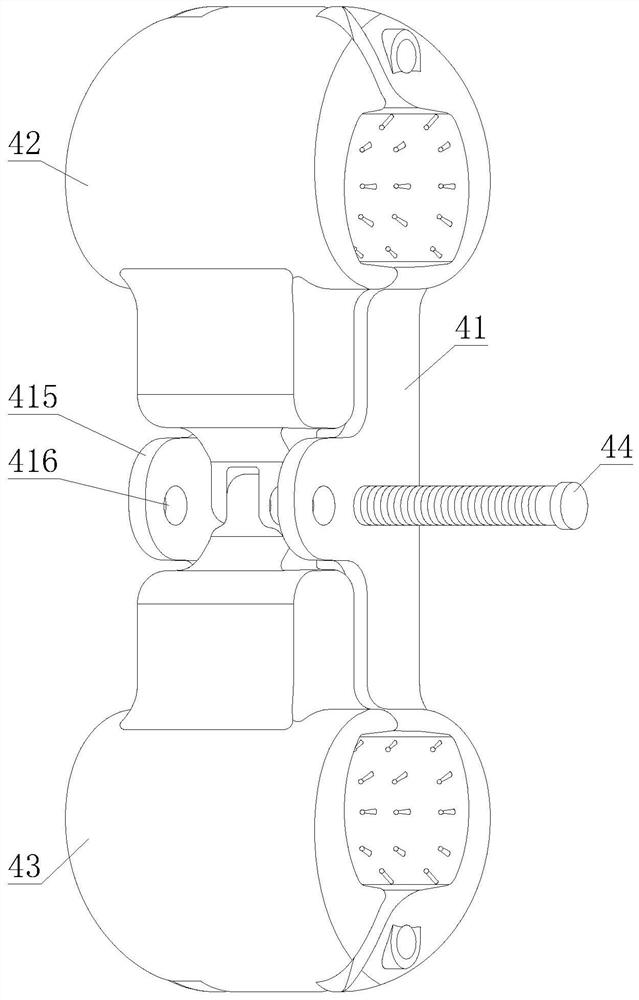

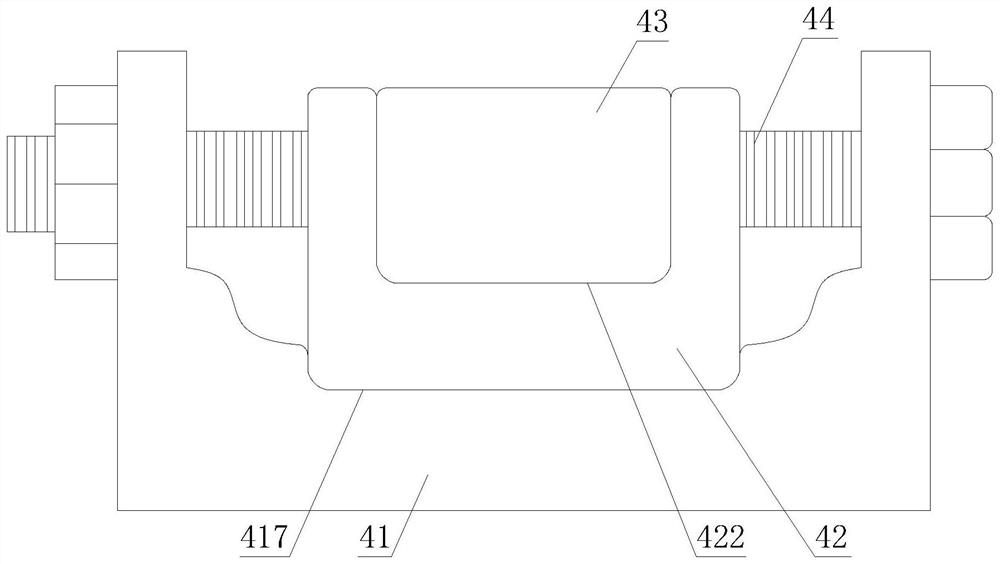

[0029] refer to Figure 1-3 , an anti-vibration hammer with a convenient replacement structure, including a left hammer head 1, a right hammer head 2, a support rod 3 and a wire clip 4, the left end of the support rod 3 is welded with the left hammer head 1, and the right end is welded with the right hammer head 2. A wire clamp 4 is installed in the middle of the support rod 3. The wire clamp 4 includes a main clamp body 41, an upper clamp body 42, a lower clamp body 43 and a locking bolt 44. The upper end of the main clamp body 41 is provided with a right half twisting groove 411 , and the top of the right half-strand groove 411 is welded with an upper rotating rod 412, and the inner walls of the right half-strand groove 411, the left half-strand groove 421, the right half support rod groove 413, and the left half support rod groove 431 are all provided with Dense pins 419, twisted wires are connected between the right half-twisting wire slot 411 and the left half-twisting wi...

Embodiment 2

[0038] refer to Image 6 , there are two wire clips 4, and the side ears 415 of the two wire clips 4 are extended outward and welded to each other to form a double wire clip 4, which is suitable for two twisted wires parallel to each other.

[0039] refer to Figure 7 , in order to better demonstrate the processing flow of the anti-vibration hammer with a convenient replacement structure, this embodiment now proposes a processing technology for an anti-vibration hammer with a convenient replacement structure, including the following steps:

[0040] S101: Casting, pouring the molten aluminum into the casting mold with the same shape of the left hammer head 1, the right hammer head 2, the support rod 3, the main clamp body 41, the upper clamp body 42 and the lower clamp body 43, cooling and forming After obtaining the left hammer head 1, the right hammer head 2, the support rod 3, the main clamp body 41, the upper clamp body 42 and the lower clamp body 43, each single structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com