Production device of sandwich biscuits with powder fillings

A production device and a technology for sandwich cakes, which are used in baking, bakery food processing, food science, etc., can solve the problems of large production line, high manufacturing cost, and difficult manufacturing and realization, and achieve compact structure, control manufacturing cost, and production cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

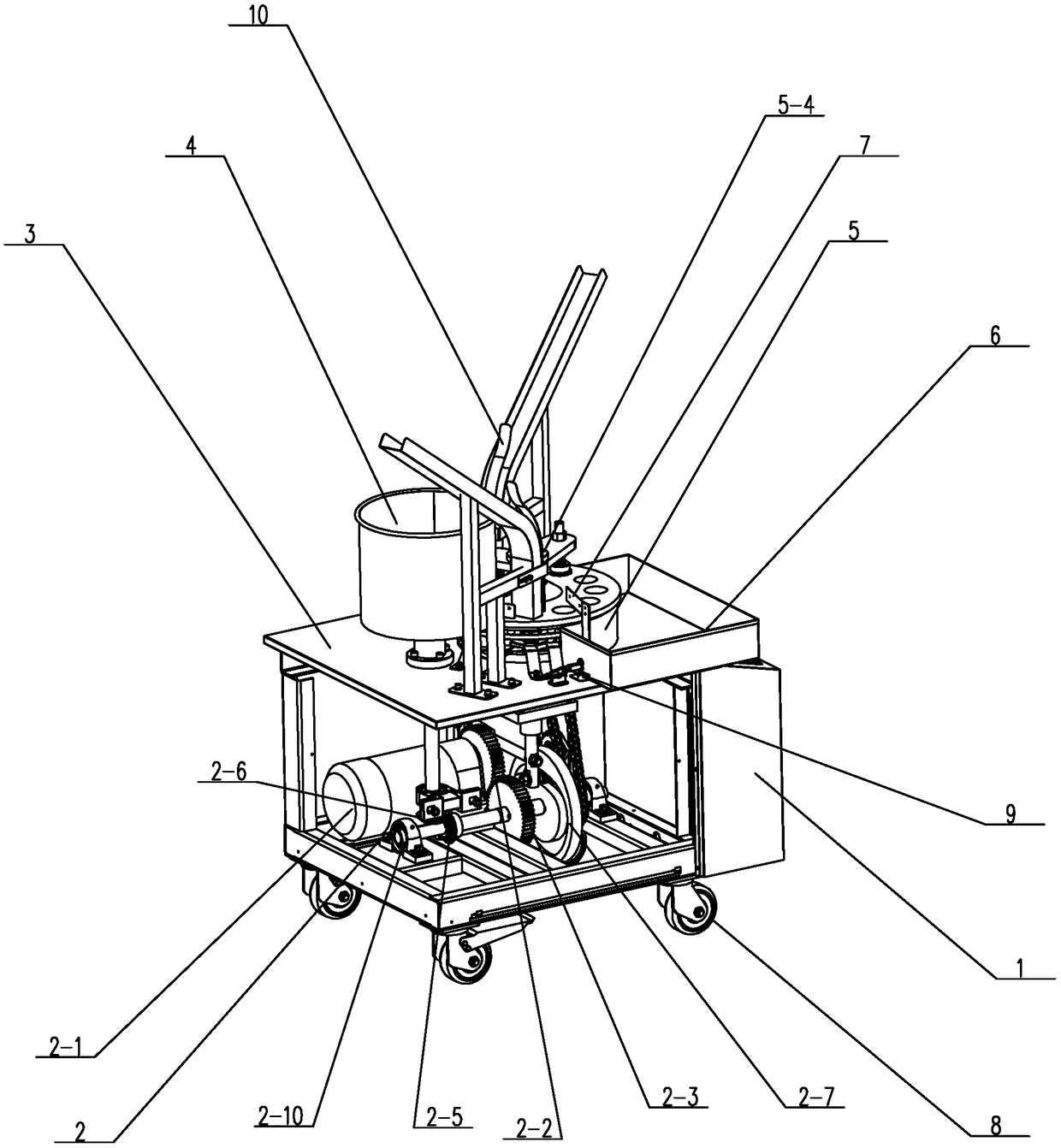

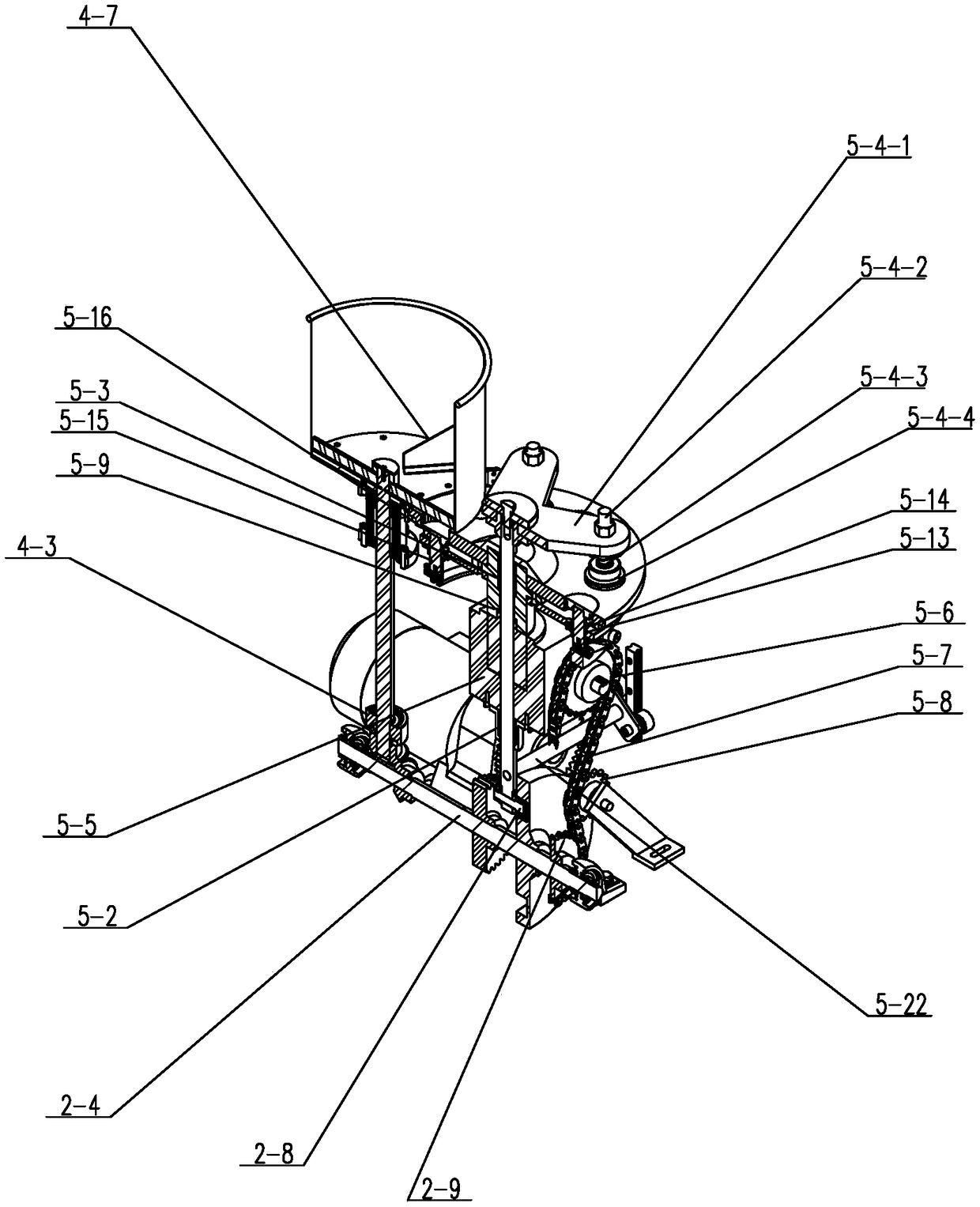

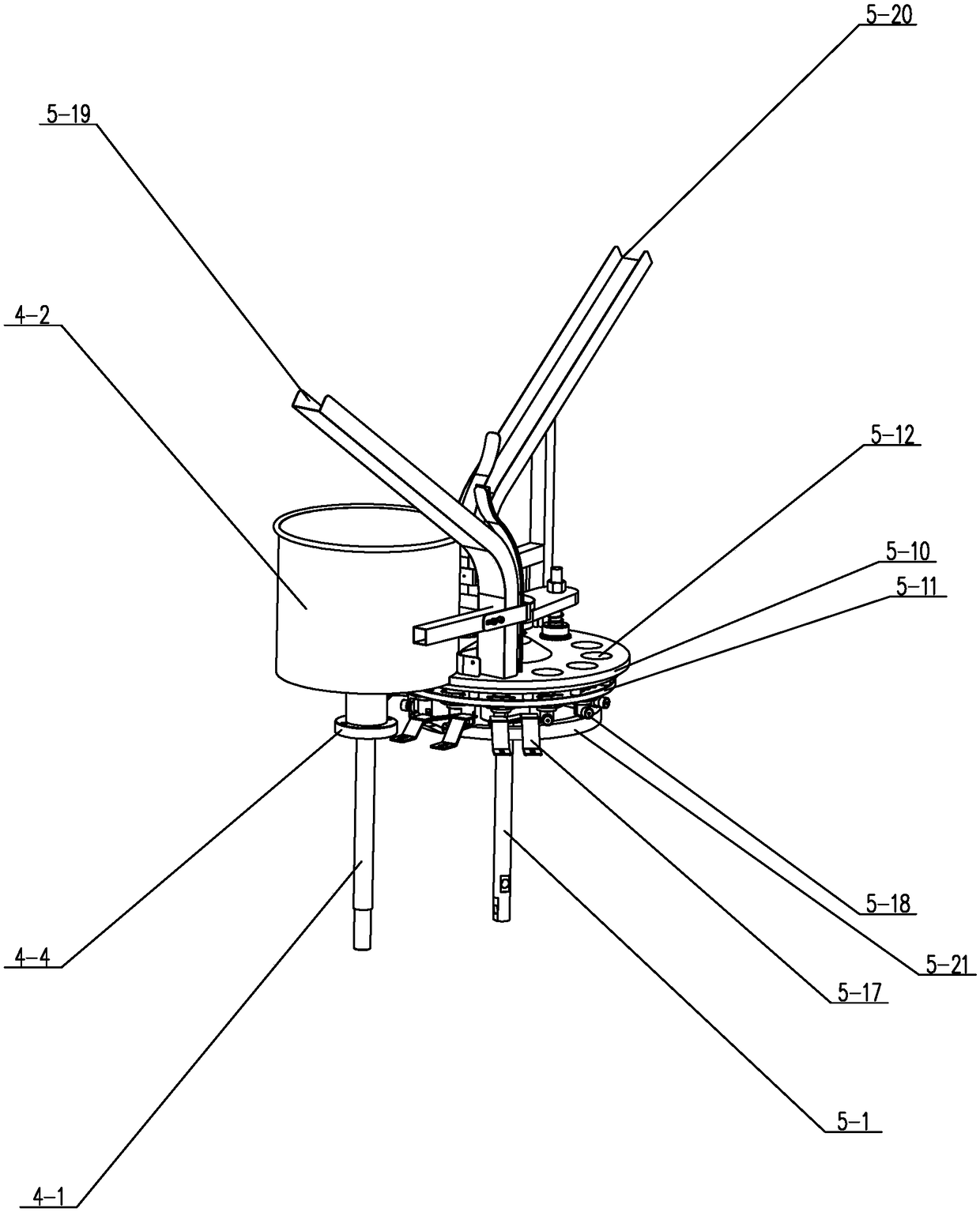

[0025] Such as figure 1Propose a kind of specific embodiment of the present invention as shown, the powder stuffed sandwich cake production device comprises frame 1, and described frame 1 is provided with driving mechanism 2, and present embodiment is provided with frame 2 and is cuboid shape, and described driving mechanism 2 is arranged in the frame 1, and the driving mechanism 2 includes a driving source 2-1 arranged on the frame 1. In this embodiment, the driving source 2-1 is set as a motor, and the output end of the driving source 2-1 is connected to A driving gear 2-2, the driving gear 2-2 meshes with the driven gear 2-3, the driven gear 2-3 is sleeved with a driving main shaft 2-4 transversely fixed on the frame 1, this Embodiment UCP bearing housings 2-10 are arranged at both ends of the driving main shaft 2-4 to fix the driving main shaft 2-4 on the frame 1, and an input bevel gear 2-5 is sleeved on the front end of the driving main shaft 2-4, The input bevel gear 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com