Intersecting-free straw strip-shaped return-to-field cultivation method for maize tillage

A cultivation method and straw technology are applied in the field of corn ploughing without staggered straw strip returning to the field, which can solve the problems of decreased resource utilization efficiency, weakened soil buffering capacity, large inter-annual variation of yield, etc., so as to improve sowing quality and alleviate Nitrogen competition and the effect of reducing the barriers to emergence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

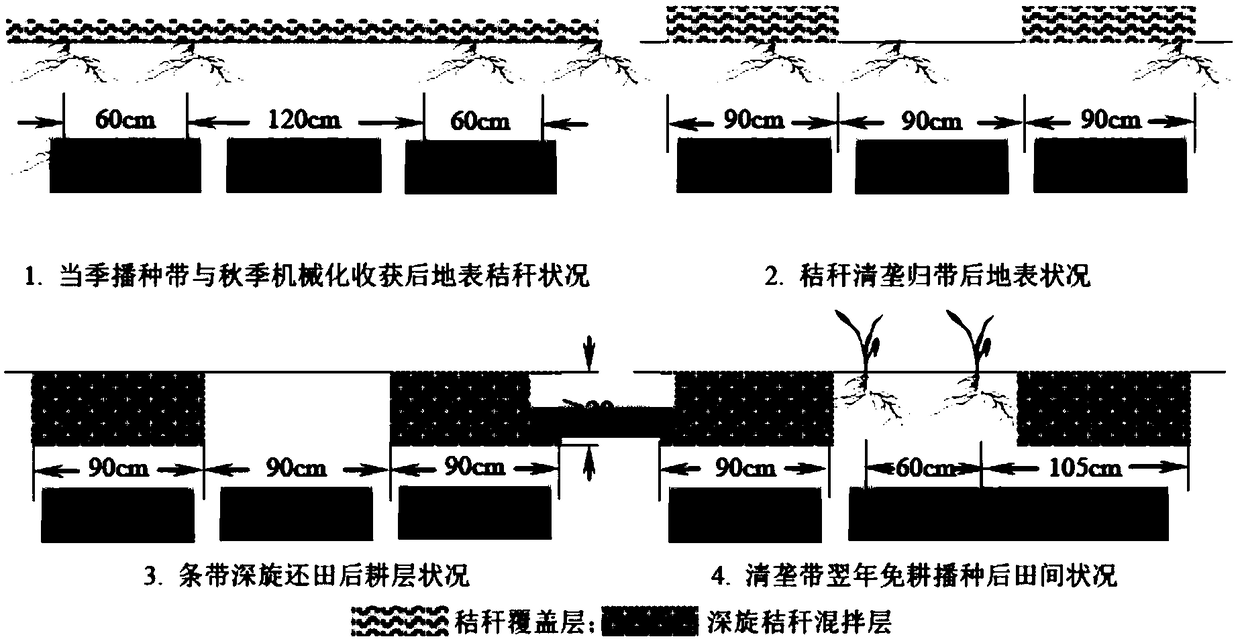

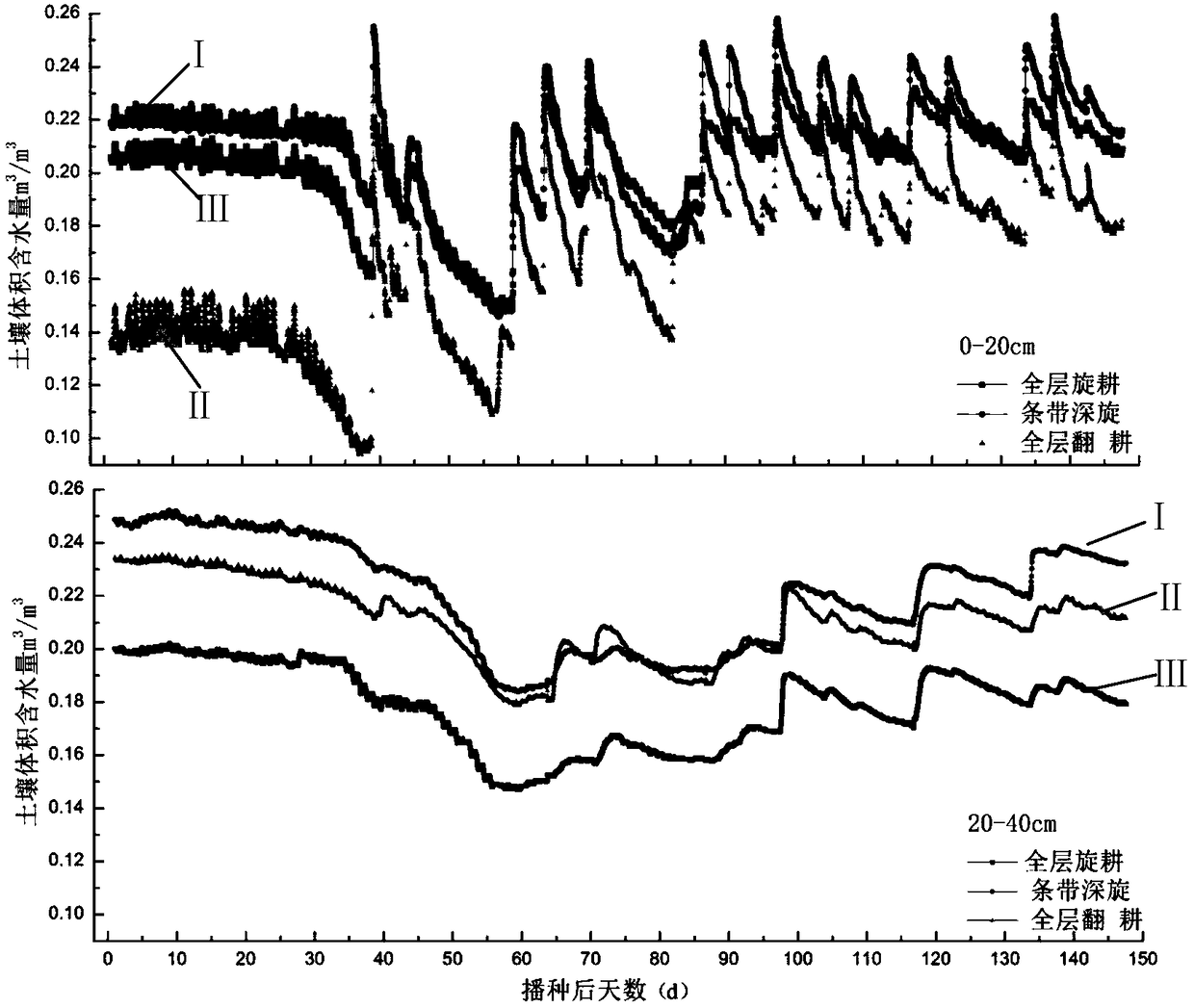

[0051] Such as figure 1 As shown, the corn tillage-free staggered straw strip returning cultivation method includes the following steps:

[0052] (1) Corn is cultivated in double-space (120cm+60cm) or wide-narrow rows (80cm+40cm).

[0053] (2) After the corn combine harvester harvests in autumn, the stubble cutter is used to crush and stubble again before winter (or before spring sowing).

[0054] (3) Before winter (or before sowing), use a corn stalk strip rotary tillage machine to return the crushed corn stalks flat on the surface to the belt (the next year’s sowing belt) and bring it back to the field (returning belt). The widths of clearing ridges and returning belts cultivated in wide and narrow rows are 90cm, 90cm, 70cm, and 50cm respectively, and the straws in the returning belts (returning belts) are deeply rotated and mixed evenly in the soil layer of 0-≥30cm, and the ridges are cleared (sowing in the next year) Belt) The residual ratio of straw is ≤5%.

[0055] (4...

Embodiment 2

[0068] The method for cultivating corn tillage without staggered strips of straw returning to the field comprises the following steps:

[0069] Step 1. Before corn sowing, the corn stalks of the previous season are first crushed and stubble removed, and then the crushed corn stalks are cleared and returned to the belt for the first time. The residual ratio of corn stalks in the first sowing belt is ≤ 5%. . Finally, mix the corn stalks at the return belt into the soil layer, and the corn stalks at the return belt are mixed in the soil at a depth of 0 to ≥ 30 cm, so that the first sowing belt is formed at the clearing ridge, and the first planting belt is formed at the return belt. Return the field belt.

[0070] Step 2. Before sowing the next season of corn, the harvested corn stalks are also firstly cleaned and crushed in situ, and then the ground corn stalks are cleaned for the second time and returned to the belt. The second sowing belt The residual ratio of corn stalks is...

Embodiment 3

[0074] A method for cultivating corn tillage without staggered strips of straw returning to the field, comprising the following steps:

[0075] Step 1. Before sowing soybeans, the soybean straw of the previous season is first crushed and stubble removed in situ, and then the crushed soybean straw is cleared and brought back for the first time, and then spread on the surface of the soybean straw flat on the ground. Apply treatment agent 3.5kg / m 2, and then use the plastic film 6 to cover the plot, treat for 17.5 days, finally remove the plastic film 6, and then mix the straw at the belt into the soil layer; wherein, the treatment agent includes the following parts by weight Components: 90 parts of decomposed farmyard manure, 4 parts of superphosphate, 0.75 parts of cellulase and 7.5 parts of water. Finally, the stalks at the return zone are mixed in the soil layer, and the depth of mixing the soybean stalks at the return zone in the soil layer is 0 cm, that is, the stalks are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com