Chopping and filament-drawing flail knife

A knife-throwing and wire-drawing technology, applied in cutting equipment, agricultural machinery and implements, applications, etc., can solve problems such as troublesome operation, time-consuming work, and a large amount of manpower, and achieve a reasonable and novel structure design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

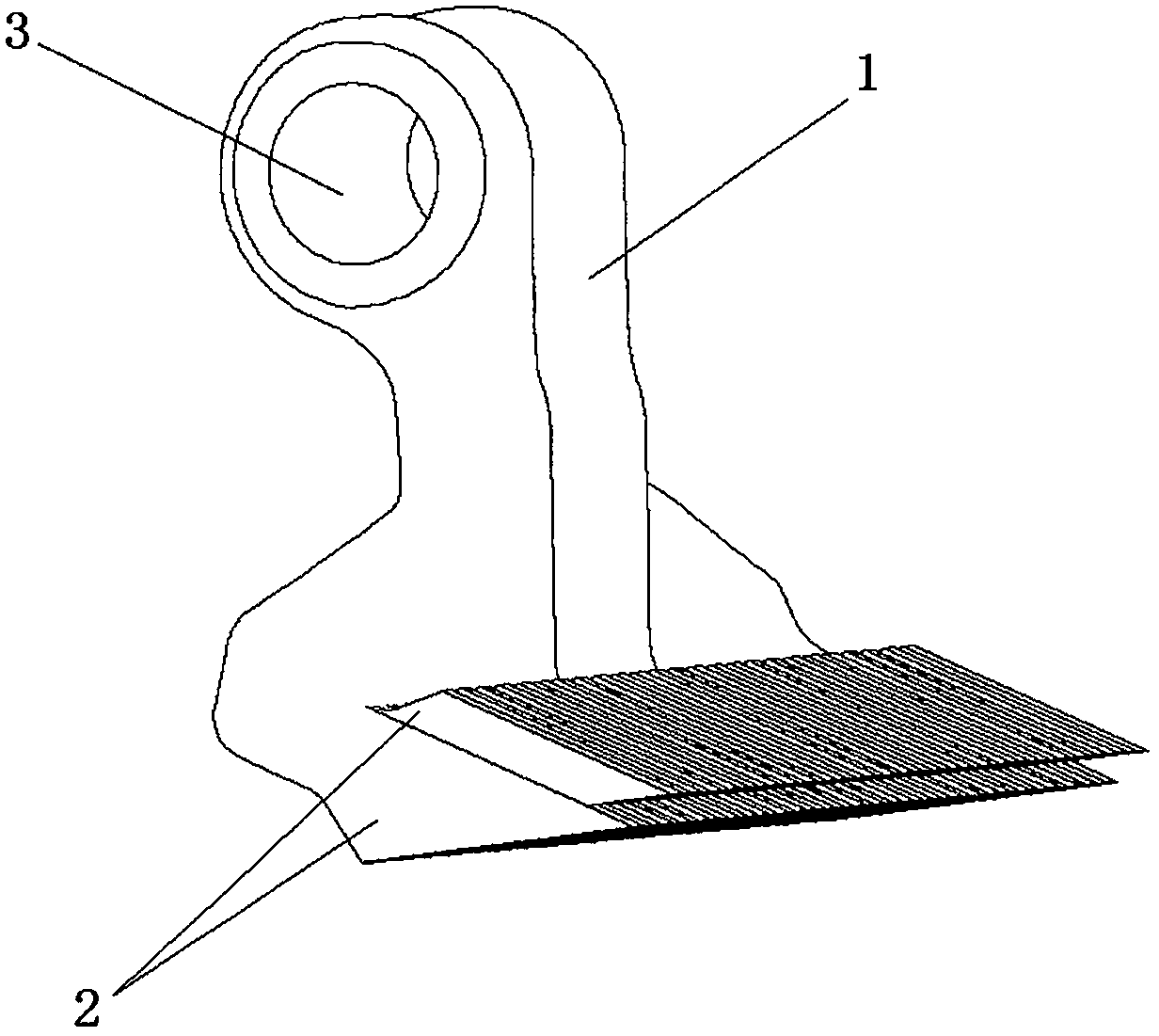

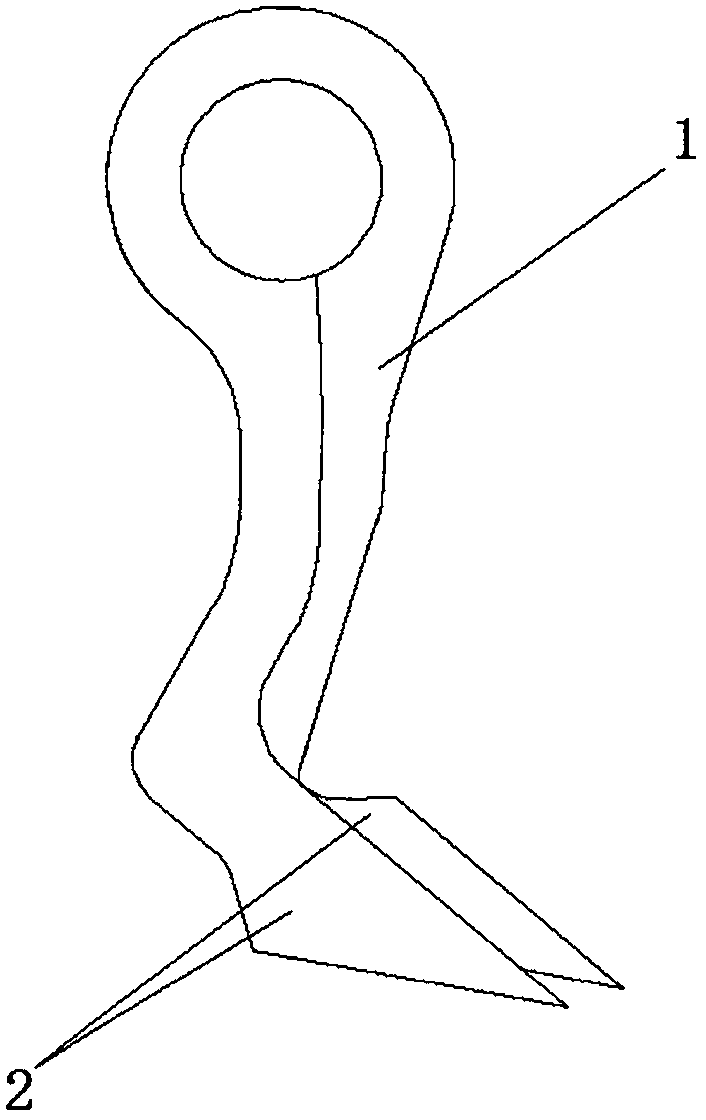

[0015] Specific implementation mode one: please refer to Figure 1-3 , the present invention provides a technical solution: a chopping and drawing flinging knife, comprising a flinging knife body 1, a flinging blade 2 and a mounting hole 3, the upper part of the flinging knife body 1 is provided with a mounting hole 3, and the lower part of the flinging knife body 1 is arranged There are two layers of throwing blades 2, and the two layers of throwing blades 2 are arranged in a staggered arrangement up and down.

[0016] Preferably, the flail knife body 1 and flail blade 2 are formed by integral casting or forging of metal materials.

specific Embodiment approach 2

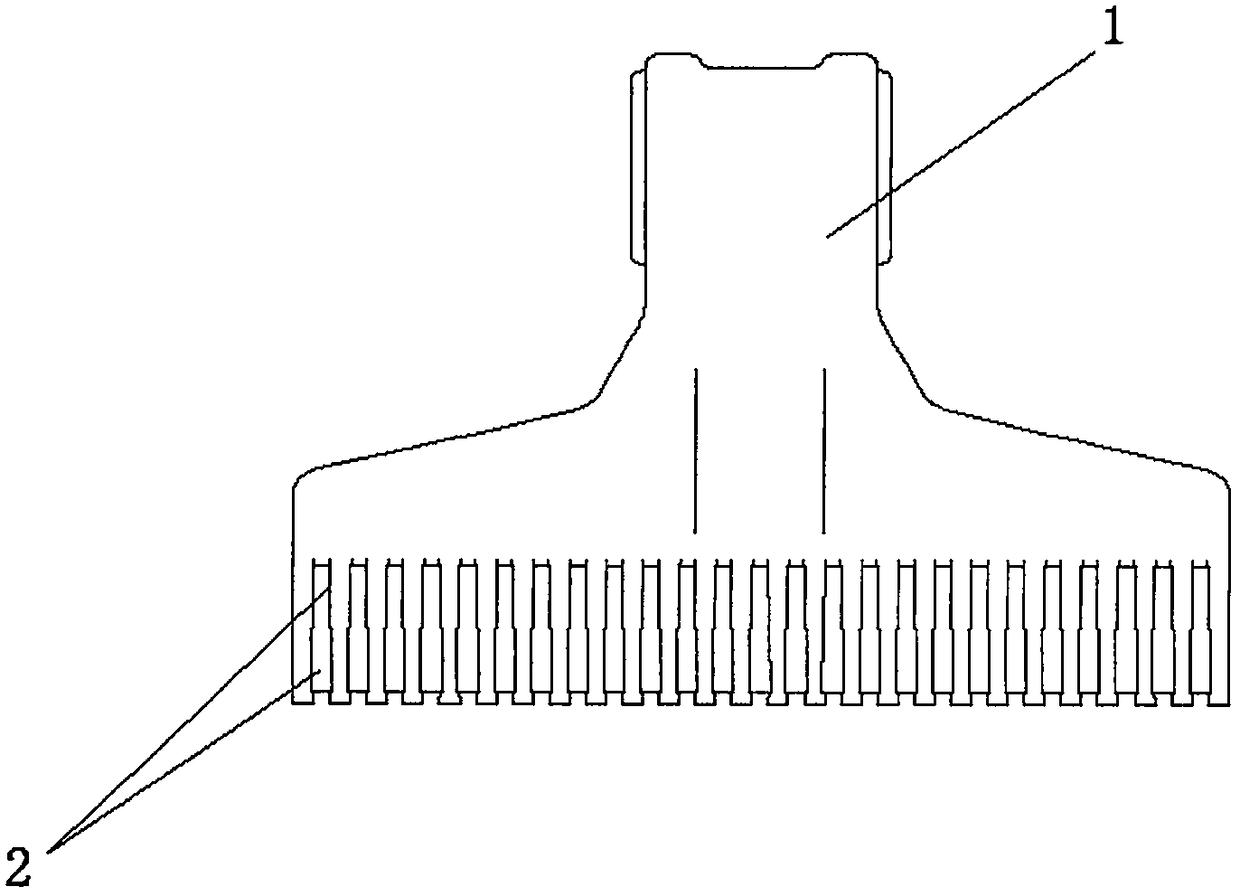

[0017] Specific implementation mode two: refer to Figure 4-6 The difference between this specific embodiment and specific embodiment 1 is that there are three or more layers of flail blades 2 under the flail body 1, and the three or multi-layer flail blades 2 are arranged in a staggered manner. , the other composition and connection methods are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com