High- and low-temperature switching test module

A test module, high and low temperature technology, applied in the field of test modules that can quickly switch between high and low temperatures, can solve the problems of expensive refrigeration chips, low production efficiency, and high temperature conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

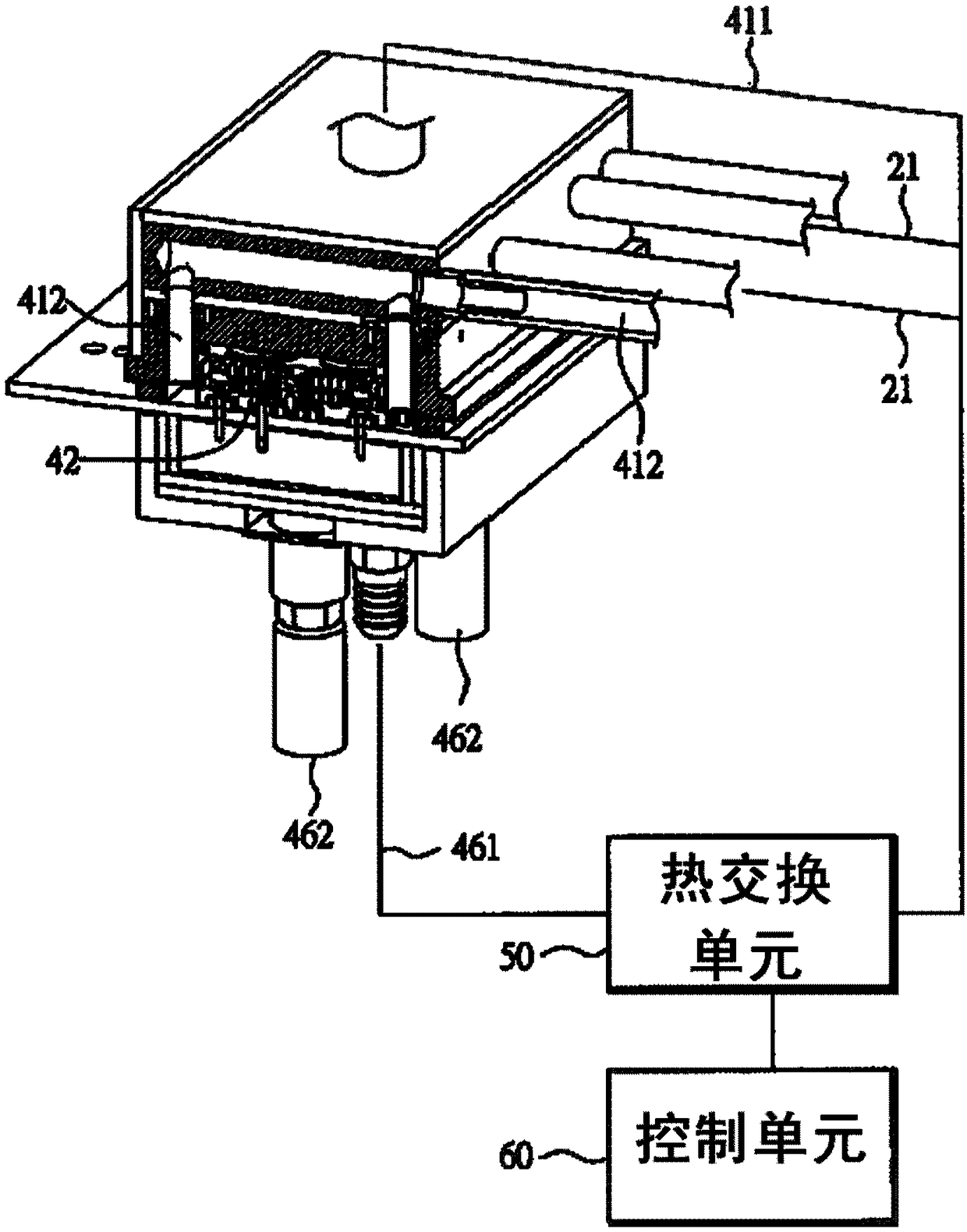

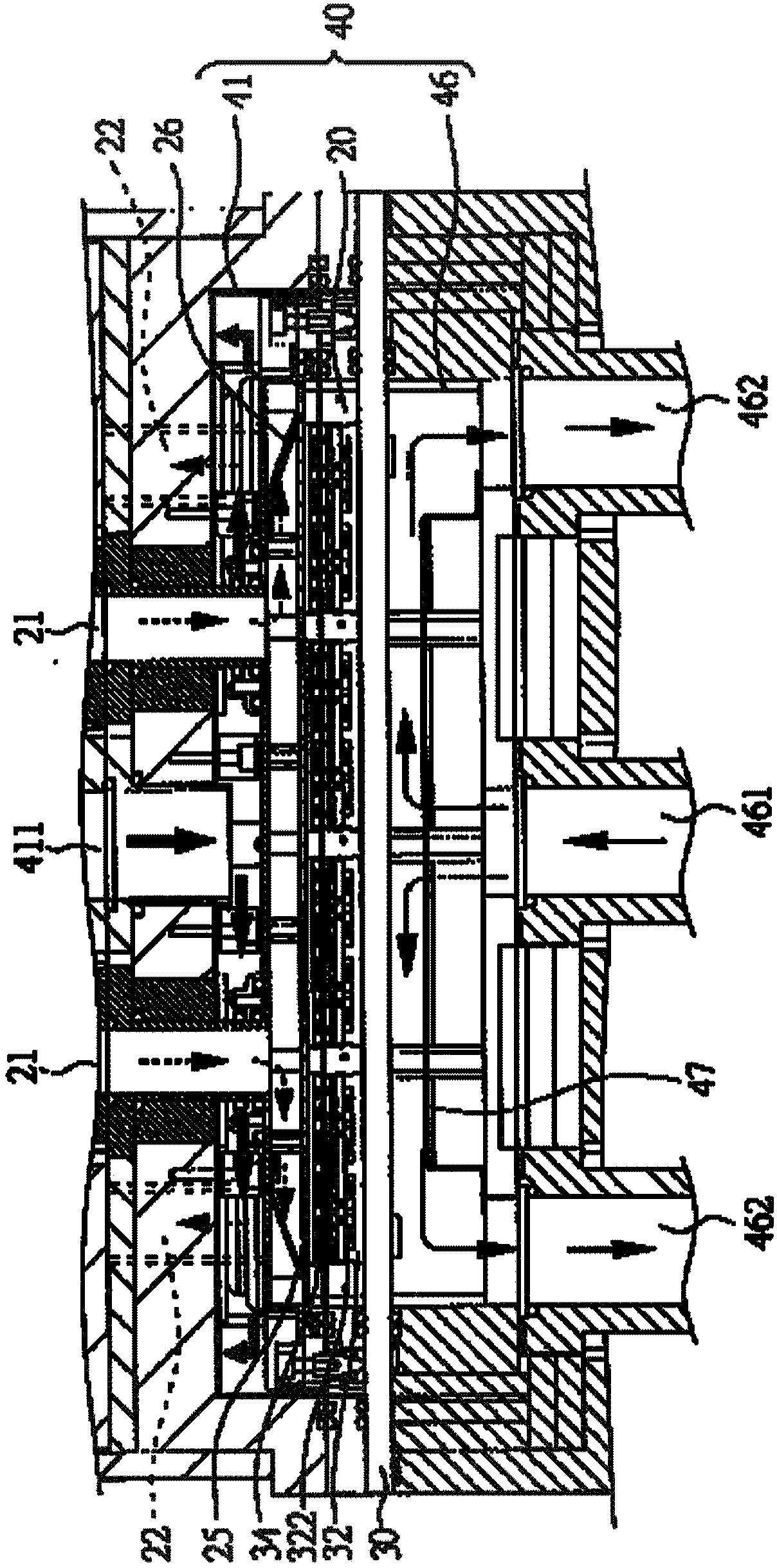

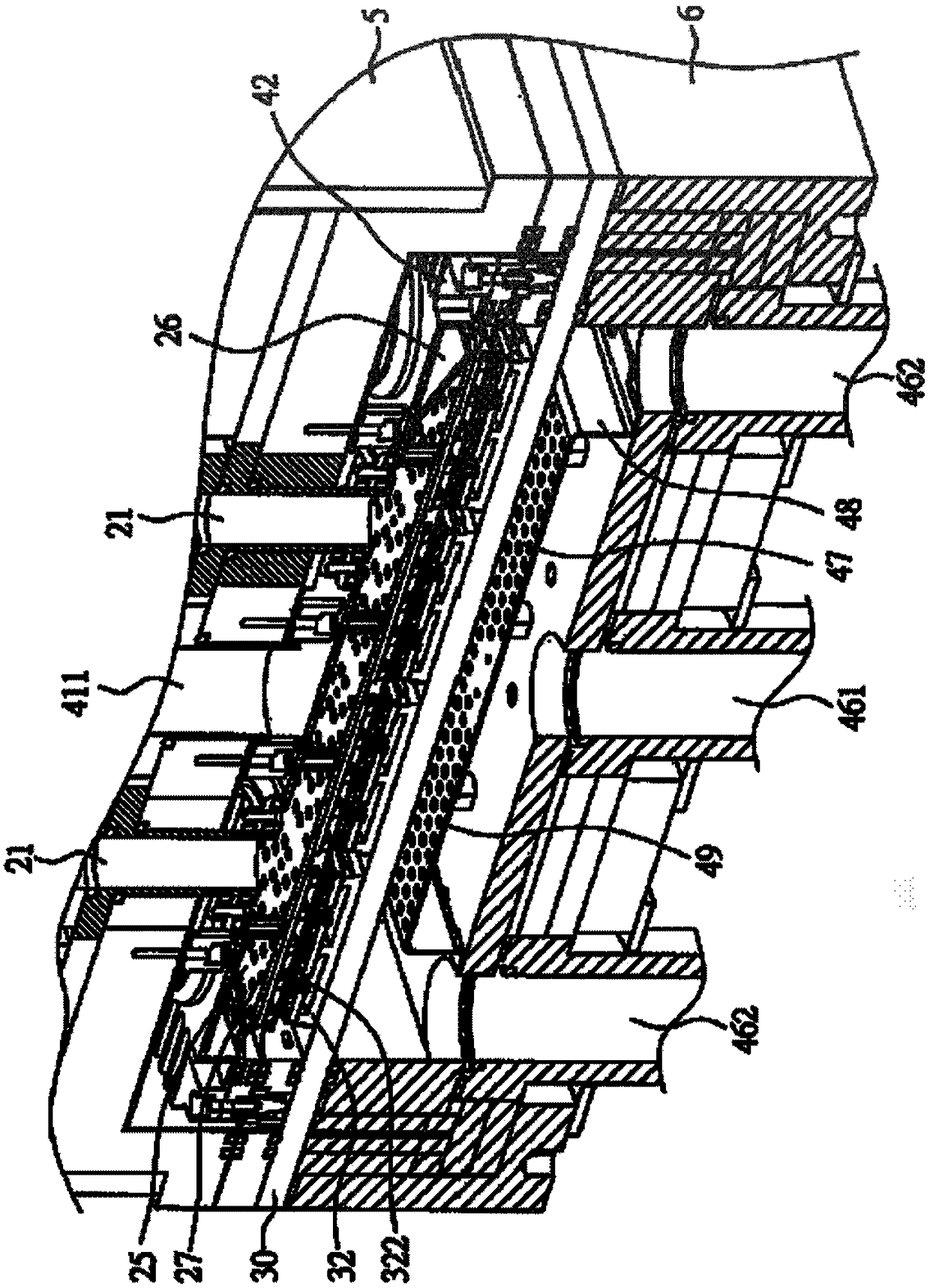

[0033] Please refer to figure 1 , figure 2 and image 3 , which are respectively a schematic diagram of a high-low temperature switching test module and two cross-sectional views from different viewing angles in a preferred embodiment of the present invention. The high and low temperature switching test module of the present embodiment includes: an inner cavity 20, an outer cavity 40 having an upper cavity 41 and a lower cavity 46, a test carrier 30, a plurality of test sockets 32, a thermal The switching unit 50 and a control unit 60 . Wherein, the test carrier board 30 is separated to form an upper cavity 41, a lower cavity 46 and an inner cavity 20, and the inner cavity 20 has at least one air intake channel 21 and at least one exhaust channel 22, and a plurality of test seats 32 are arranged on A plurality of probes 322 are pierced on the test carrier 30 for placing a plurality of chips 34 to be tested; the outer cavity 40 consisting of the upper cavity 41 and the lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com