Quantitative research and study method of inner and outer spacer rings of precision shafting unit

A technology of precision shafting and inner spacer, which is used in measuring devices, mechanical bearing testing, instruments, etc. It can solve the problem that the accuracy cannot meet the production needs of modern enterprises, and the method of detecting bearing protrusion is time-consuming and labor-intensive, and it is difficult to measure and research. problems such as increasing the number of times and time, to achieve the effect of facilitating quality control, reducing the workload of workers, improving market prospects and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions of the present invention will be clearly and completely described through specific embodiments in conjunction with the accompanying drawings of the present invention. Obviously, the described embodiments are only some of the embodiments of the present invention, not all of them. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

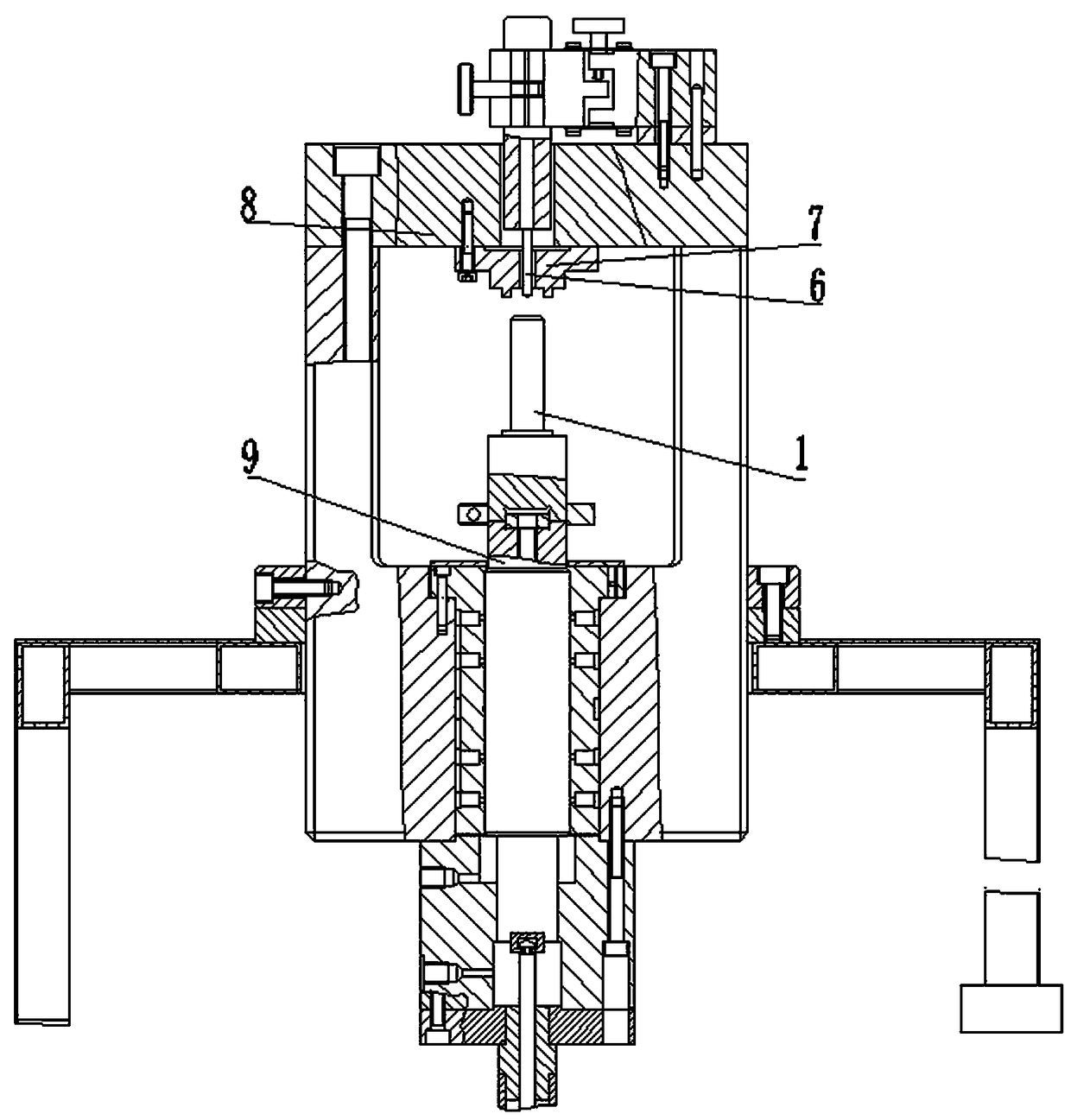

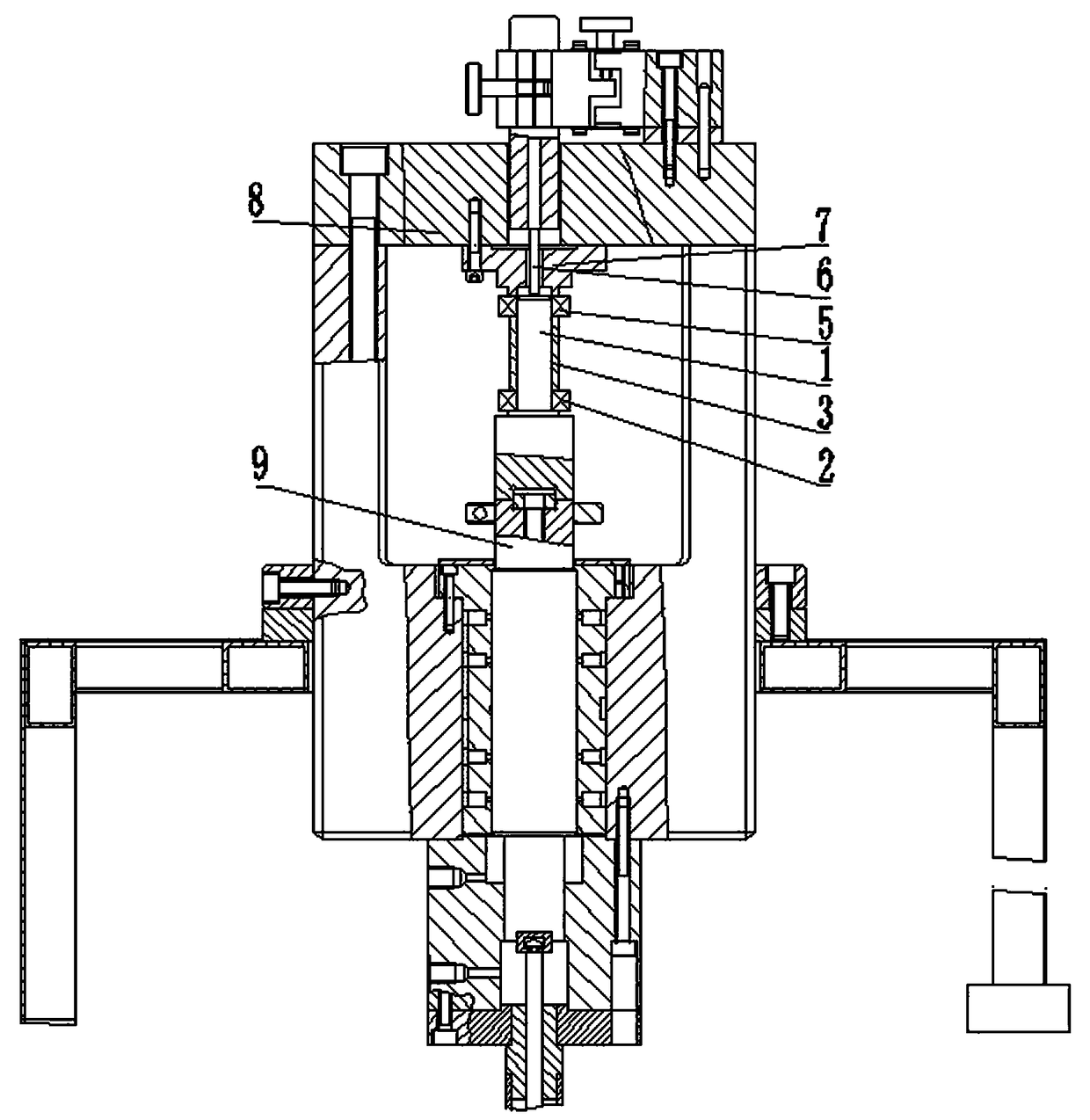

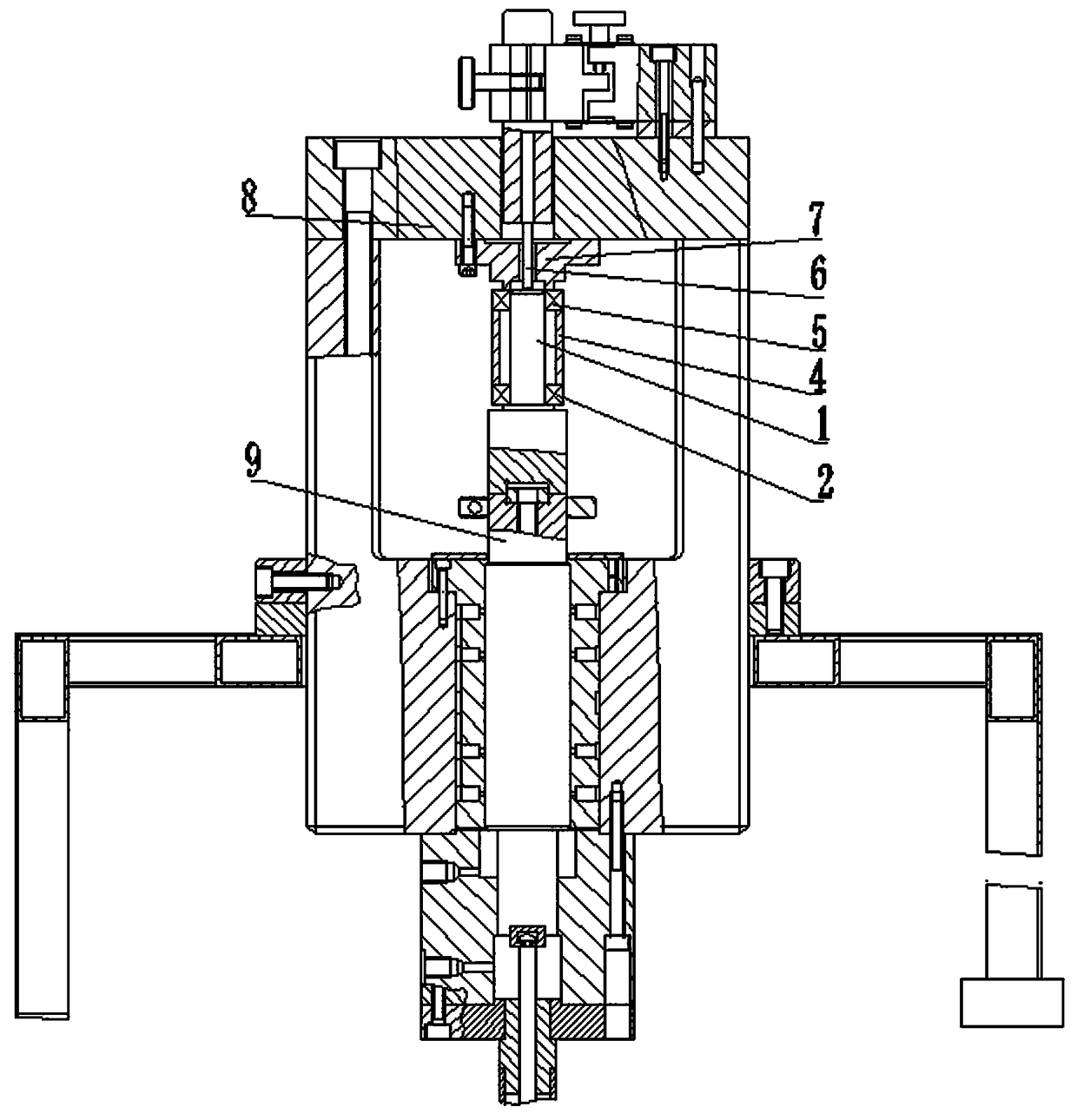

[0021] A method for quantitatively repairing inner and outer spacers of a precision shafting system is carried out by using shafting pretightening force measuring equipment. like figure 1 As shown: the shaft system preload measuring equipment is mainly composed of centering mandrel 1, lower bearing under test 2, inner spacer 3, outer spacer 4, upper bearing under test 5, displacement sensor 6, upper bearing positioning Seat tooling 7, top plate 8 and loading mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com