Large formwork narrow space wall body construction method based on integral assembly

A construction method and technology of large formwork, which are applied in the connection parts of formwork/formwork/work frame, the preparation of building components on site, construction, etc., can solve the problem that the installation and positioning accuracy of the overall formwork is difficult to guarantee, and the overall formwork hoisting construction is difficult. , wall forming quality is not easy to control and other problems, to achieve the effect of reducing the cost of construction measures, convenient assembly, and convenient connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Outer formwork and inner formwork design and construction technical requirements, on-site hoisting construction technical requirements, concrete mix ratio design and pouring construction technical requirements, bolt fastening construction technical requirements, etc., will not be described in detail in this embodiment, and the methods involved in the present invention will be focused on implementation.

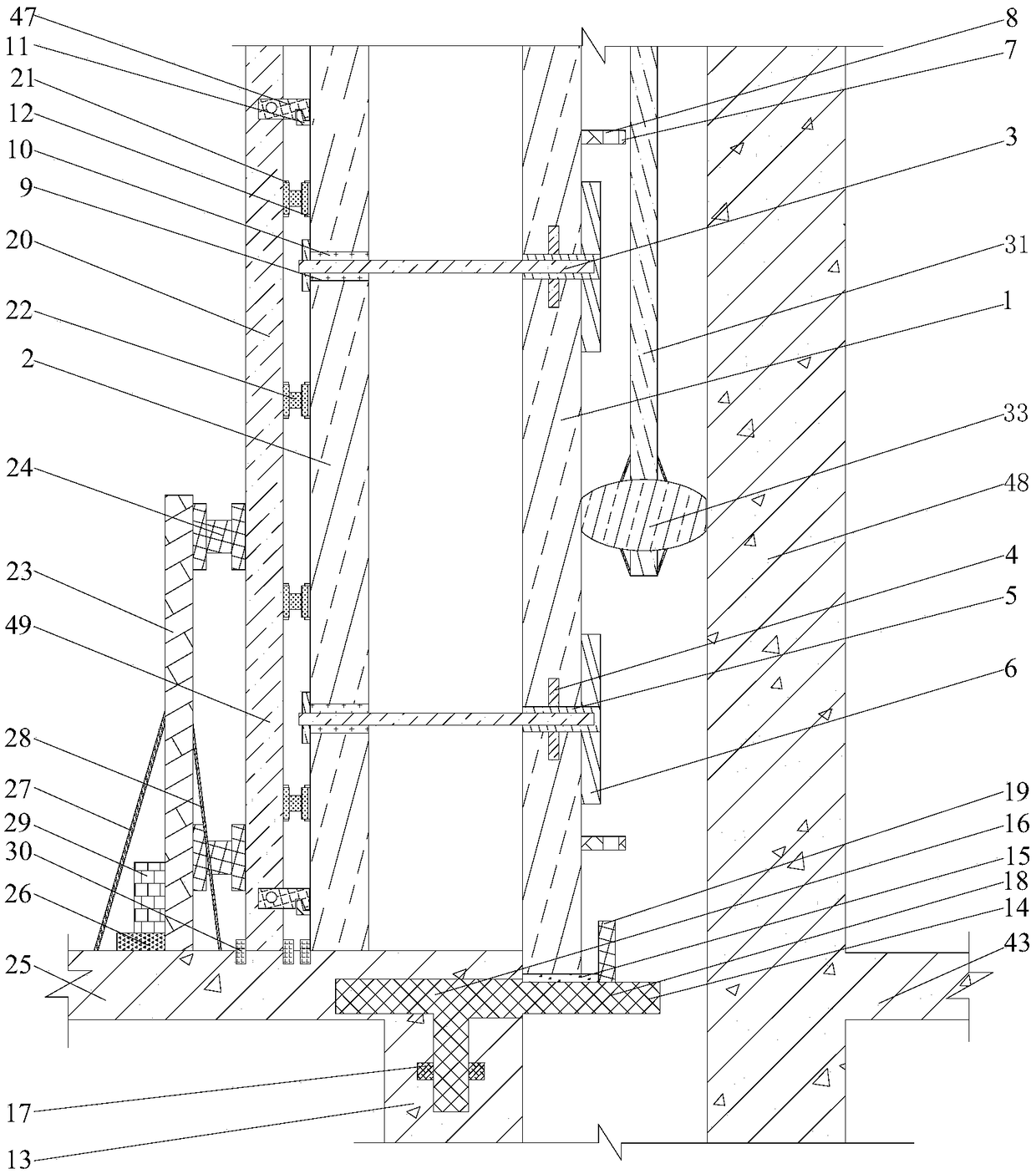

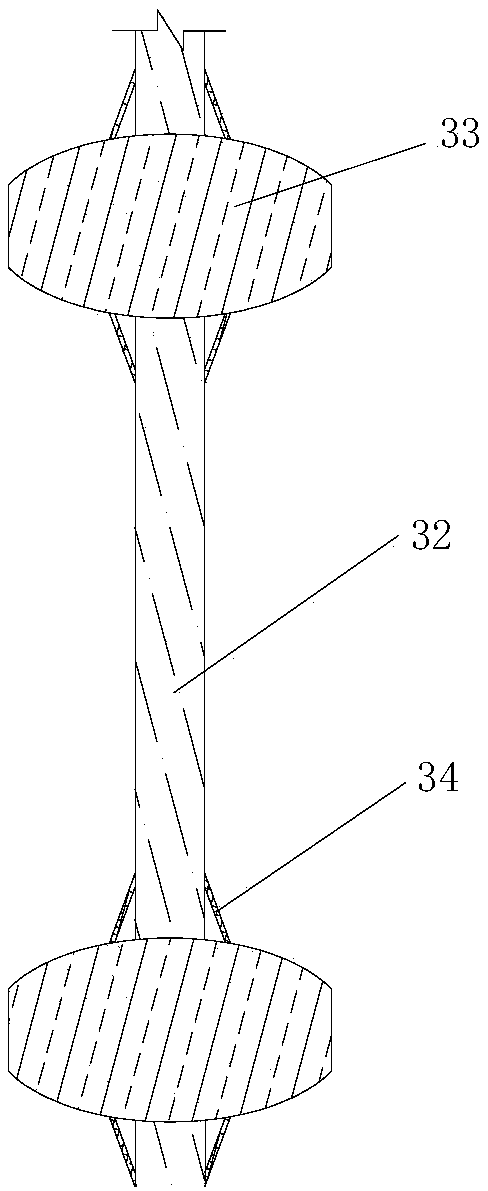

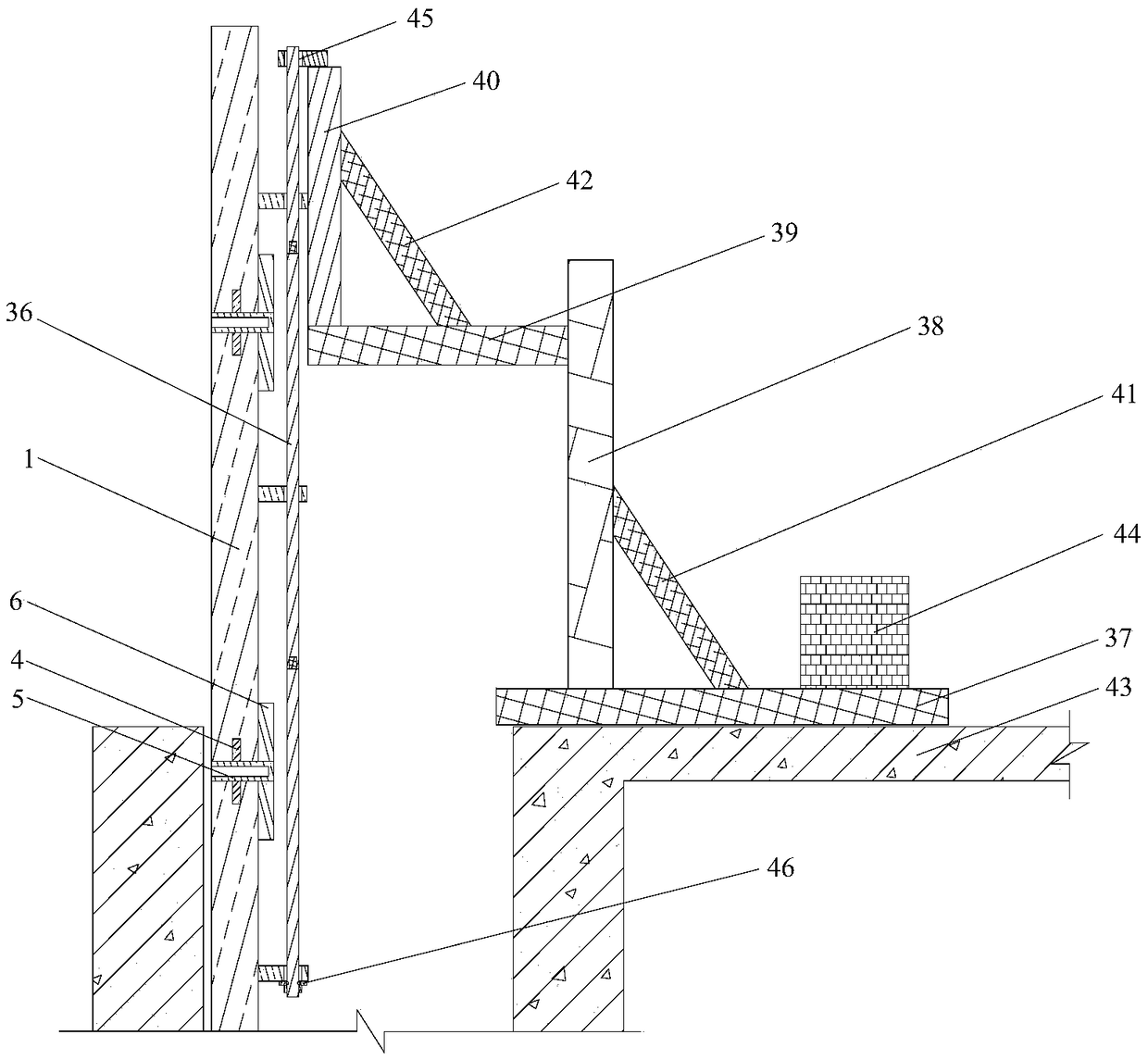

[0033] figure 1 It is a schematic diagram of the construction structure of the wall in a narrow space based on the overall assembly of large formwork in the present invention, figure 2 It is a schematic cross-sectional view of the vertical outer support structure of the present invention, image 3 It is a schematic cross-sectional view of the sliding form guide frame of the present invention after the layout is completed. refer to Figure 1 ~ Figure 3 As shown, the built-in bolt 5 connected with the pull screw 3 is arranged on the outer mold 1, and the connecting ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com