Bicycle operation mechanism

An operating mechanism, a bicycle technology, applied in the direction of bicycle gear shifting mechanism, bicycle accessories, transportation and packaging, etc., can solve the problems of enlarged stroke, enlarged finger operation stroke, discomfort, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

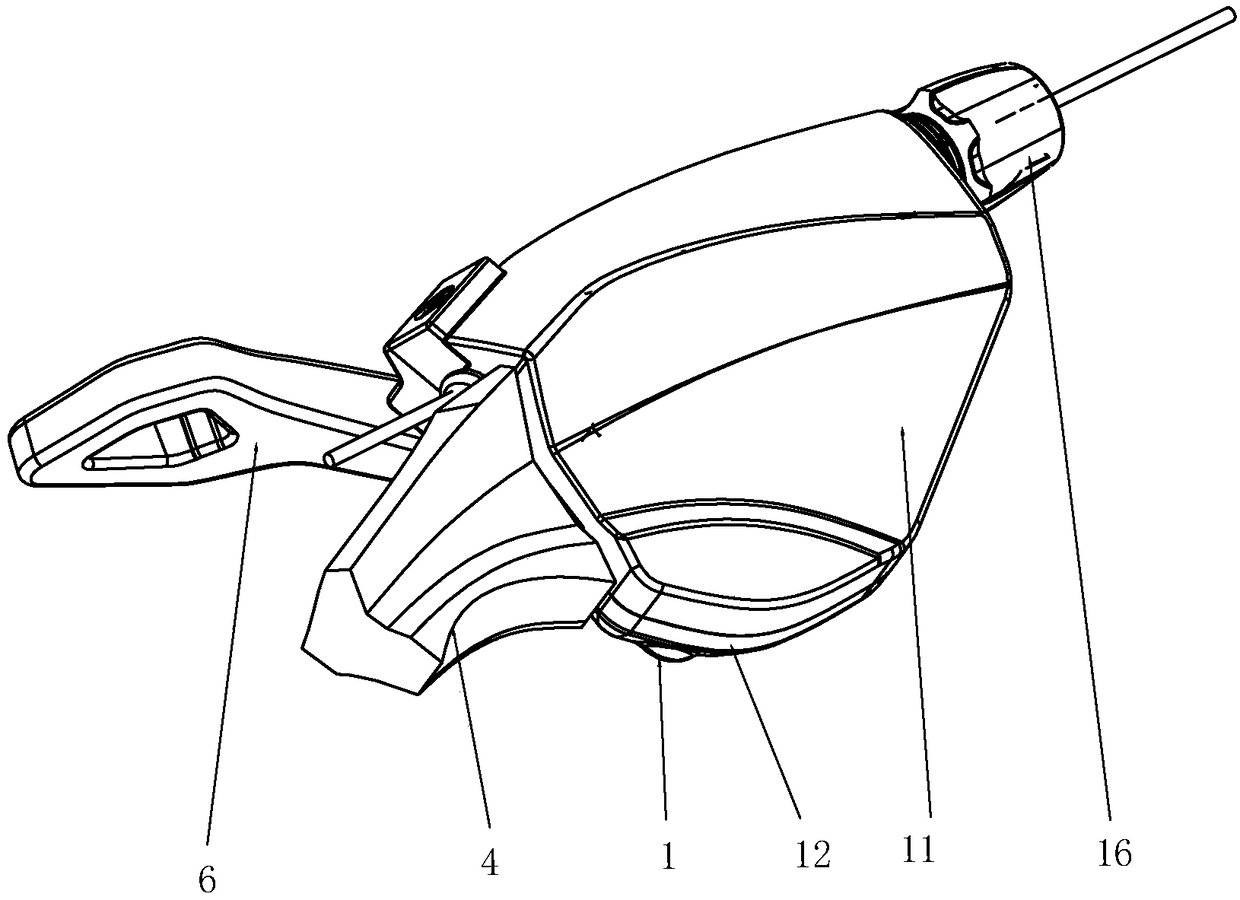

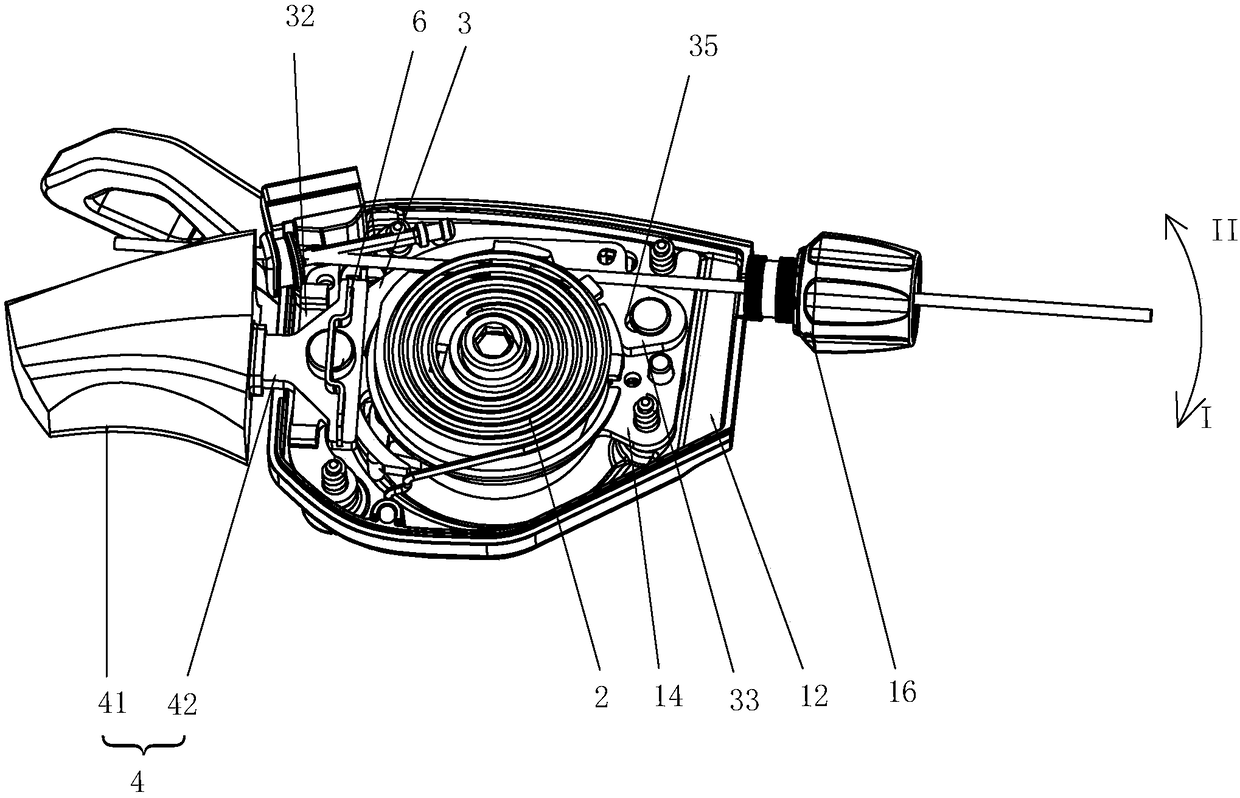

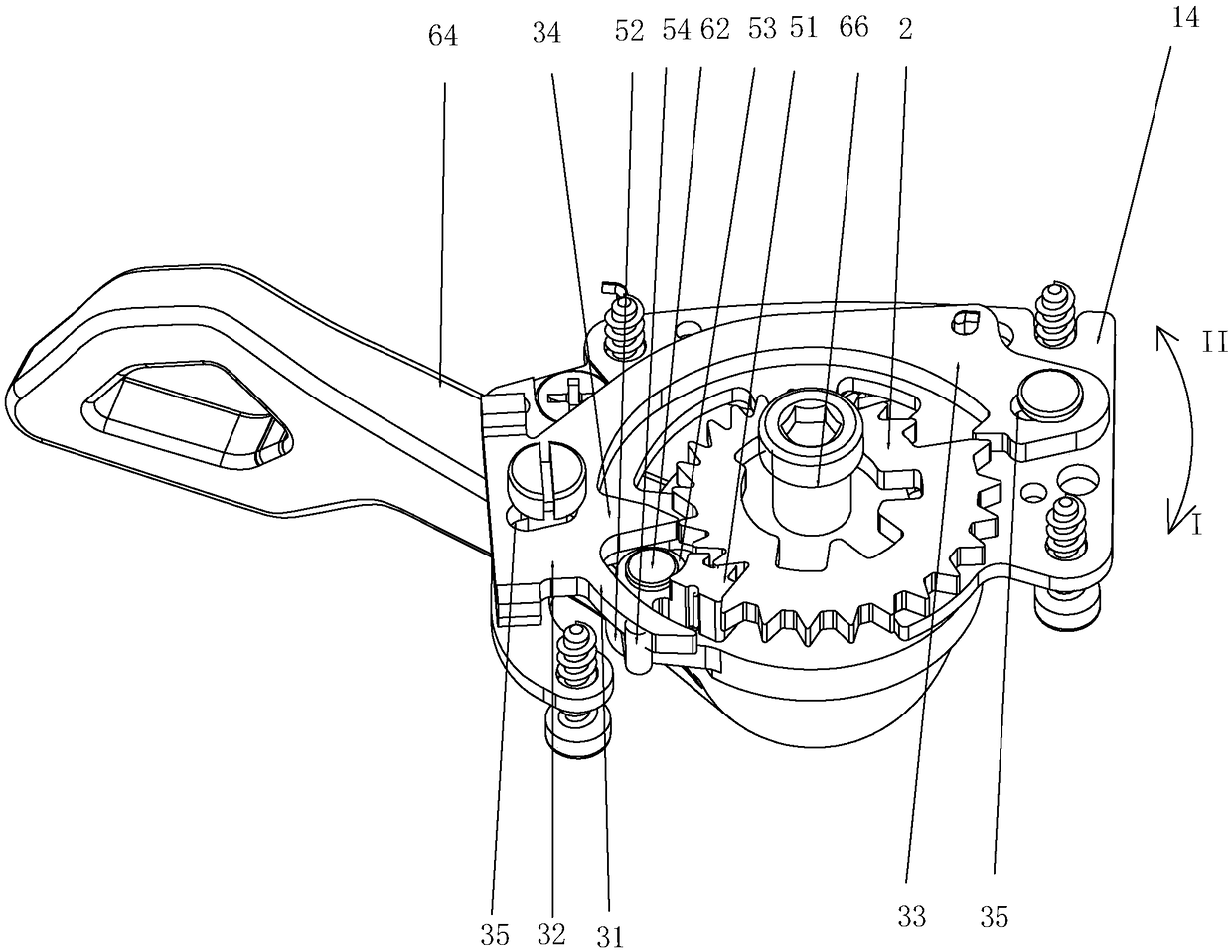

[0028] see Figure 1 to Figure 6 , a bicycle operating mechanism of the present invention, comprising a base housing 1, a ratchet assembly 2 rotatably installed in the base housing 1 and resettable, sliding between a first position and a second position to control the ratchet assembly 2. The ratchet hook member 3 that rotates clockwise or stops rotating and the lever assembly 4 used to drive the ratchet hook member 3 to move, and also includes the ratchet member 5 and the gear assembly 6 used to drive the ratchet wheel assembly 2 to rotate clockwise. It is convenient to distinguish the direction of rotation. In this application, the attached Figure 1 to Figure 5 In the figure, the direction I is counterclockwise, and the direction II is clockwise. The ratchet member 5 is rotatably mounted on one side of the gear shift assembly 6 , and the ratchet member 5 includes a toothed portion 51 capable of engaging with the ratchet assembly 2 and a swing portion 52 abutting against the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com