Super-high-density array transducer

An ultra-high-density, transducer technology, applied in ultrasonic/sonic/infrasonic diagnosis, medical science, sound wave diagnosis, etc., can solve the problems of time-consuming and labor-intensive welding of leads, difficulty in welding leads on the surface of the vibrator, etc., and achieve rapid industrialization in batches The effect of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

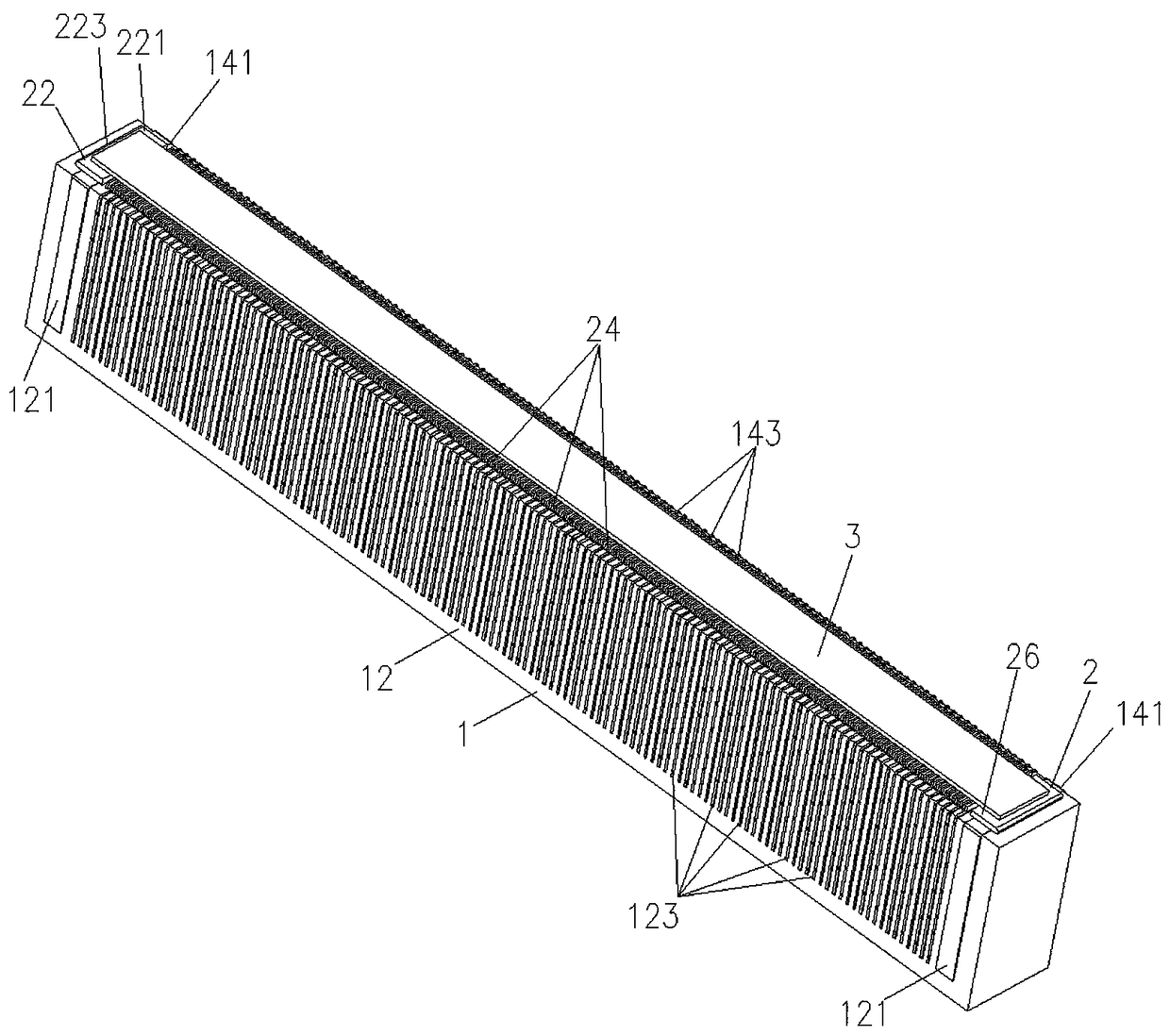

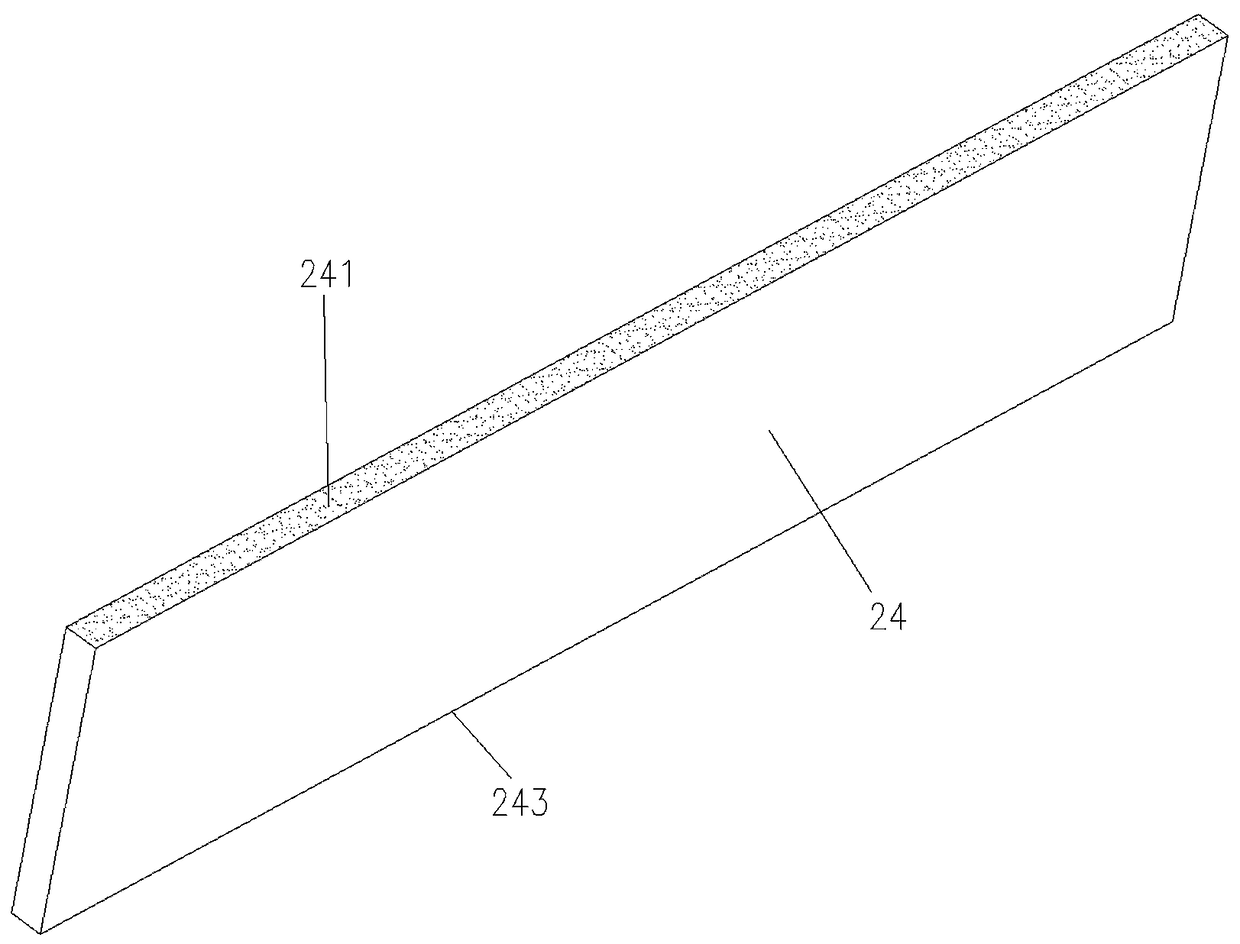

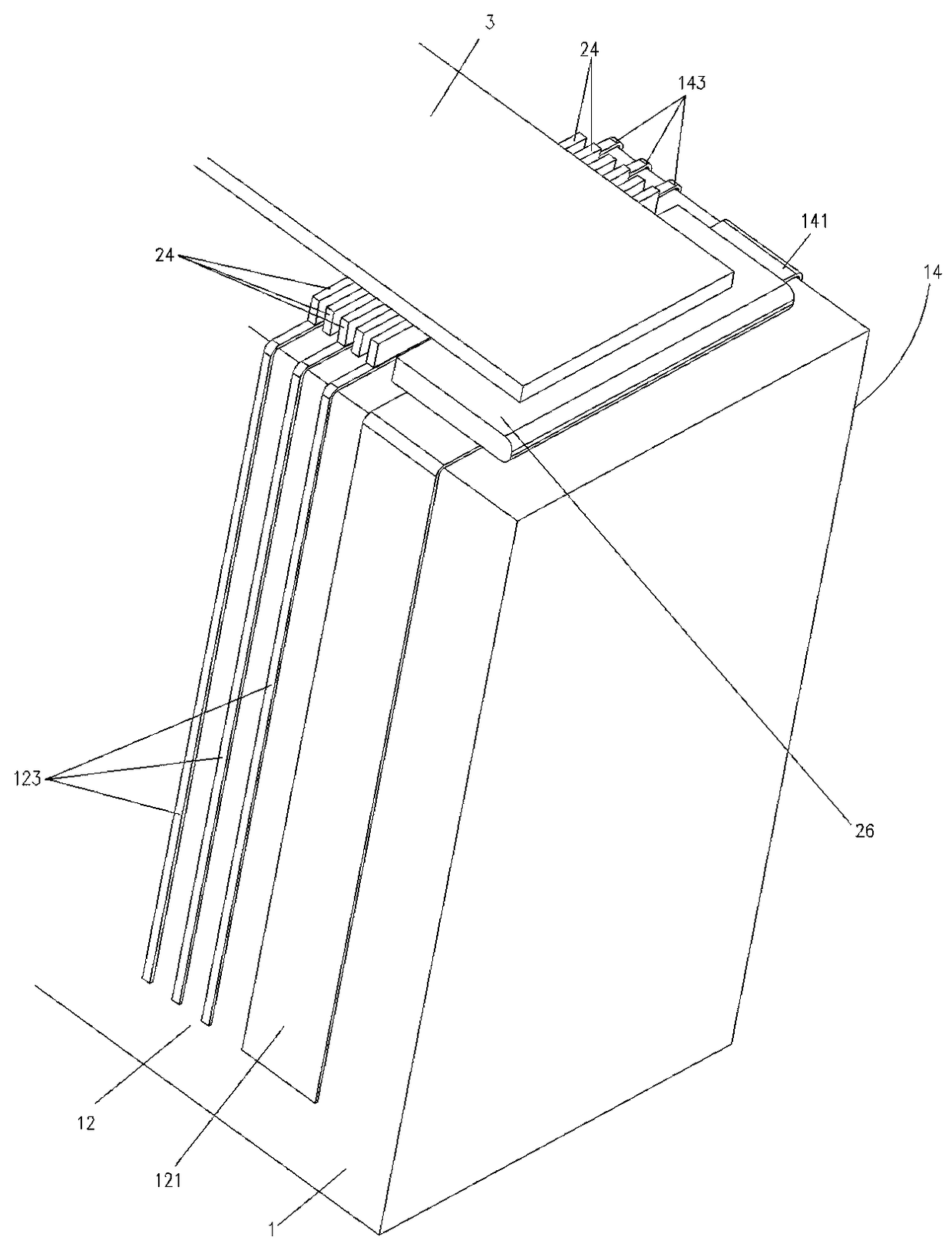

[0034] see Figure 1 to Figure 4 , an ultra-high-density array transducer, which includes a flexible printed circuit board (FPC) 1, a piezoelectric material layer 2, and a matching material layer 3.

[0035] The flexible printed circuit board 1 includes a front surface 12 and a rear surface 14 .

[0036] The left and right ends of the front surface 12 are respectively provided with a front ground lead 121 .

[0037] Several front signal leads 123 are arranged side by side between the two front ground leads 121 on the front surface 12 .

[0038] The left and right ends of the rear surface 14 are respectively provided with a rear ground lead 141 .

[0039] Several rear signal leads 143 are arranged side by side between the two rear ground leads 141 on the rear surface 14 .

[0040] Tops of the front ground lead 121 , the front signal lead 123 , the rear ground lead 141 , and the rear signal lead 143 are all arranged on the top surface of the flexible printed circuit board 1 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com