A kind of lithium-ion battery assembly method

A lithium-ion battery and battery technology, applied in secondary batteries, secondary battery repair/maintenance, circuits, etc., can solve the problems of poor battery consistency and affecting the service life of battery packs, and achieve good consistency and long service life The effect of improving the accuracy of length, voltage and K value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

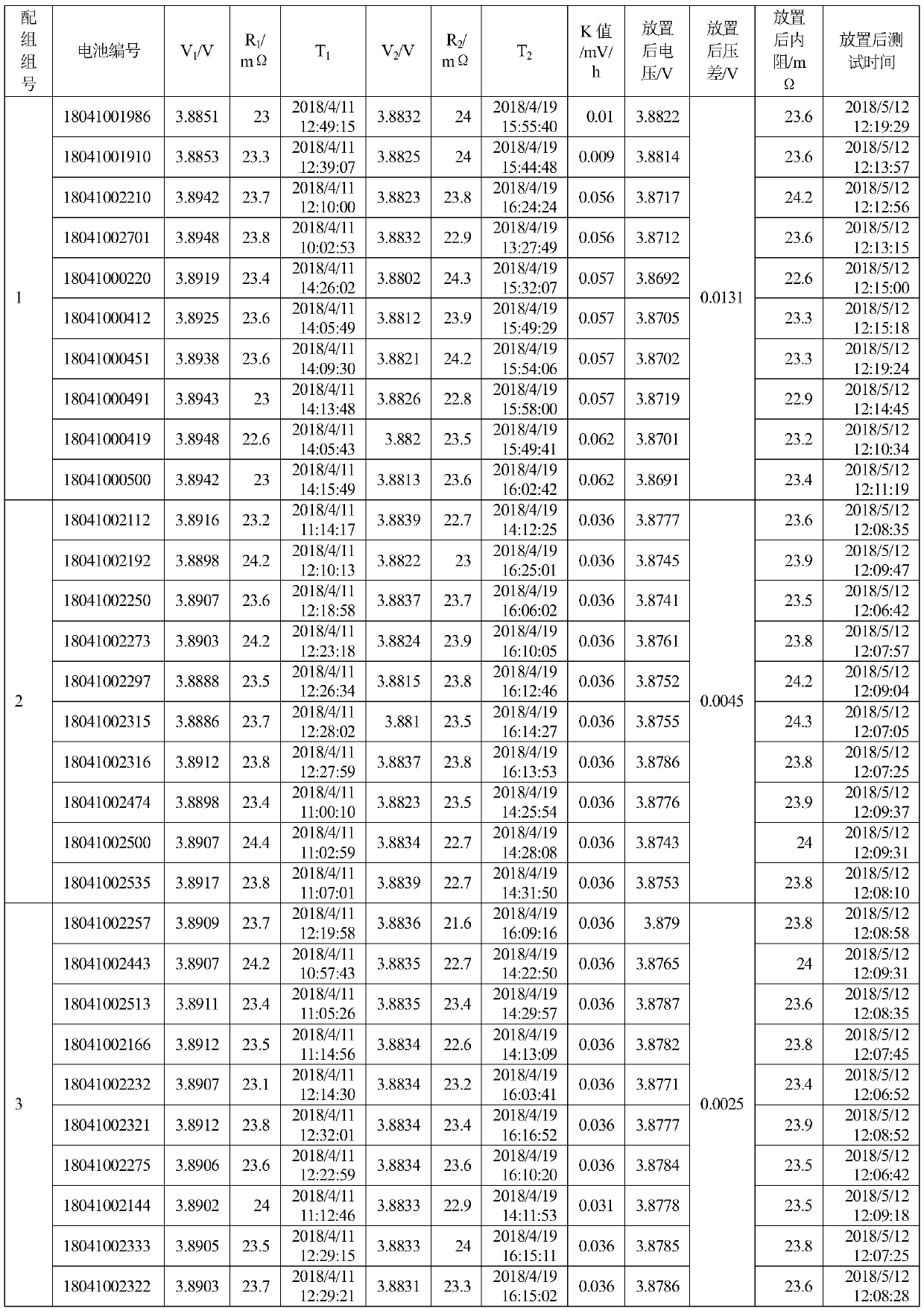

[0025] The matching method of the present invention is further described below in conjunction with the examples:

[0026] Capacity classification: Take a battery with a battery model of 805085-3600mAh as an example, and divide it into a container to test the capacity according to the following process:

[0027] 1. 1800mA constant current discharge, lower limit voltage 3.0V;

[0028] 2. Leave it on hold for 10 minutes;

[0029] 3. 1800mA constant current and constant voltage charging, upper limit voltage 4.2V, cut-off current 36mA;

[0030] 4. Leave it on hold for 10 minutes;

[0031] 5. 1800mA constant current discharge, lower limit voltage 3.0V;

[0032] 6. Leave it on hold for 10 minutes;

[0033] 7. 1800mA constant current and constant voltage charging, upper limit voltage 3.9V, cut-off current 36mA;

[0034] 8. Stop.

[0035] After the capacity test process is over, classify the lithium batteries according to the discharge capacity of the above process 5, and classif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electric potential / voltage | aaaaa | aaaaa |

| internal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com