Rotor test bench and test method with spigot connection structure

A technology of connecting structure and testing method, which is applied in the test bench and testing field of the rotor of the spigot connection structure, can solve the problems of large centrifugal force, increase the overall mass of the engine, affect the structural strength of the rotor, etc., and achieve the effect of convenient installation and disassembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and technical solutions.

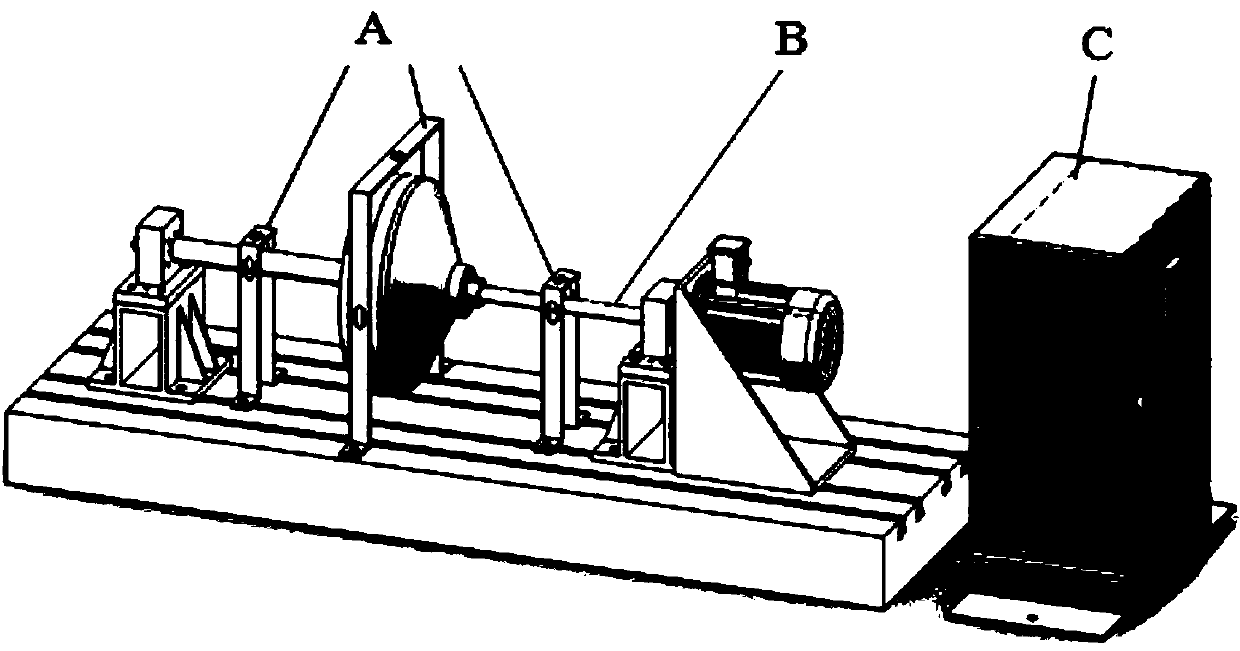

[0031] Such as figure 1 As shown, the present invention is a test device for rotor vibration characteristics considering the spigot connection structure, which mainly includes an electrical control box C, a rotor-support system B and a test sensing system A.

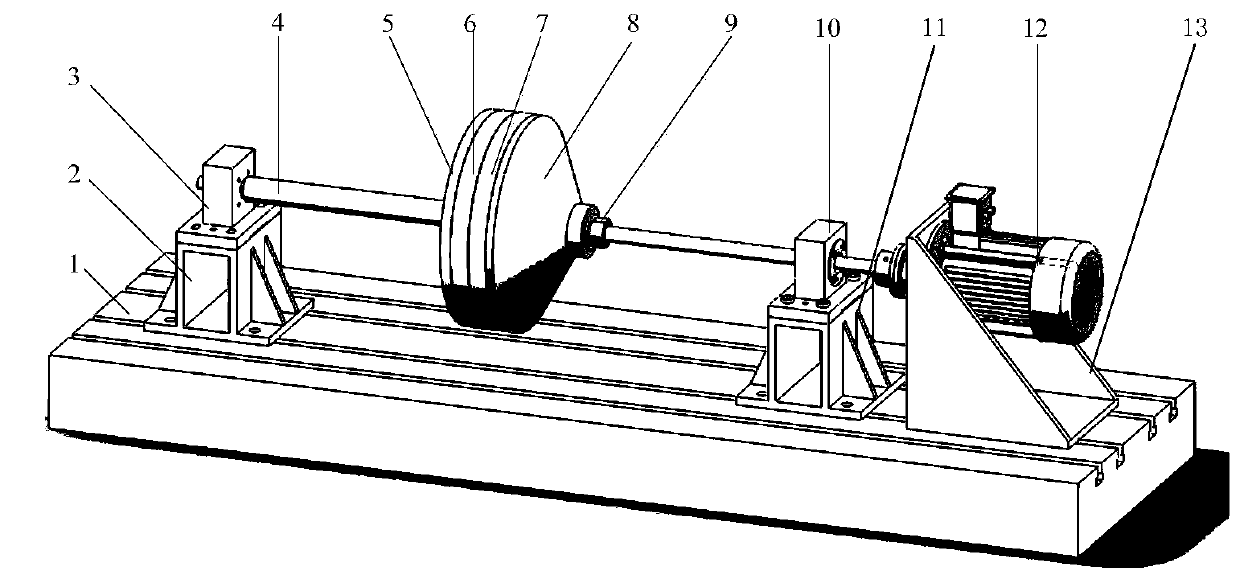

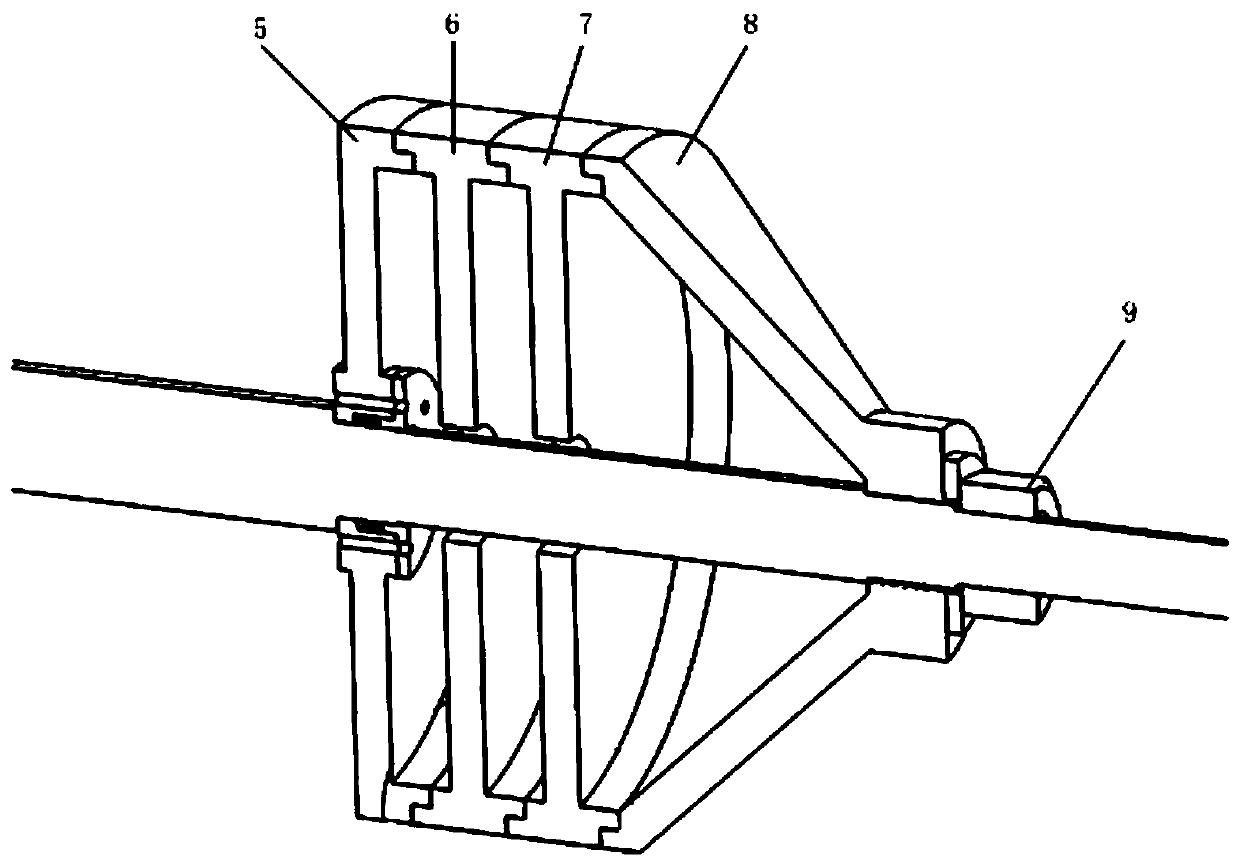

[0032] The rotor-support system B, such as figure 2 with image 3 As shown, it includes base 1, rotating shaft 4, left fixed plate 5, left spigot plate 6, right spigot plate 7, right conical cover 8, lock nut 9, deep groove ball bearing 16, left bearing seat 3, right Bearing seat 10, bearing seat support 2, right bearing seat support 11, variable frequency motor 12 and motor seat 13.

[0033] The base 1 is placed on a level ground, and its upper surface is provided with several T-shaped grooves. The left bearing support 2, the right bearing support 11, the mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com